Oxygen-doped modification method of two-dimensional material

A two-dimensional material and oxygen doping technology, which is applied in the field of oxygen doping modification of two-dimensional materials, can solve problems such as the inability to use selective doping, and achieve no secondary pollution, strong universality, and high accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

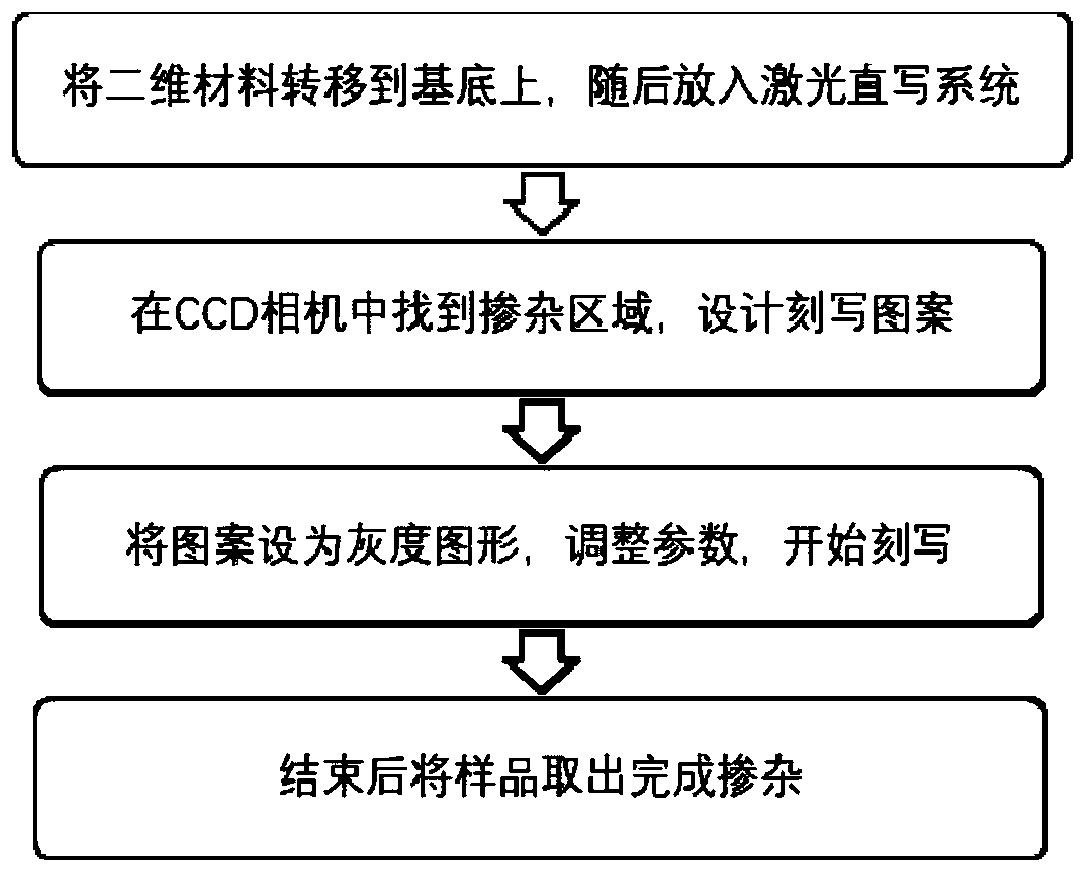

[0061] This embodiment provides a method for modifying two-dimensional materials by oxygen doping, the specific steps of which are as follows:

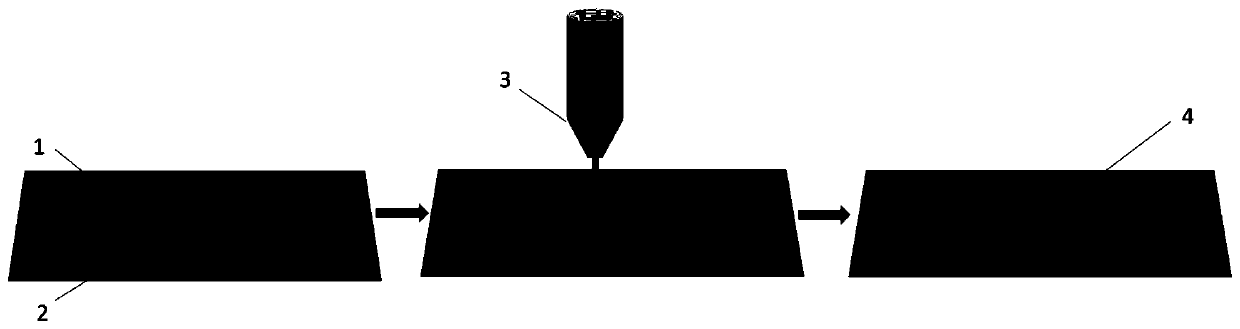

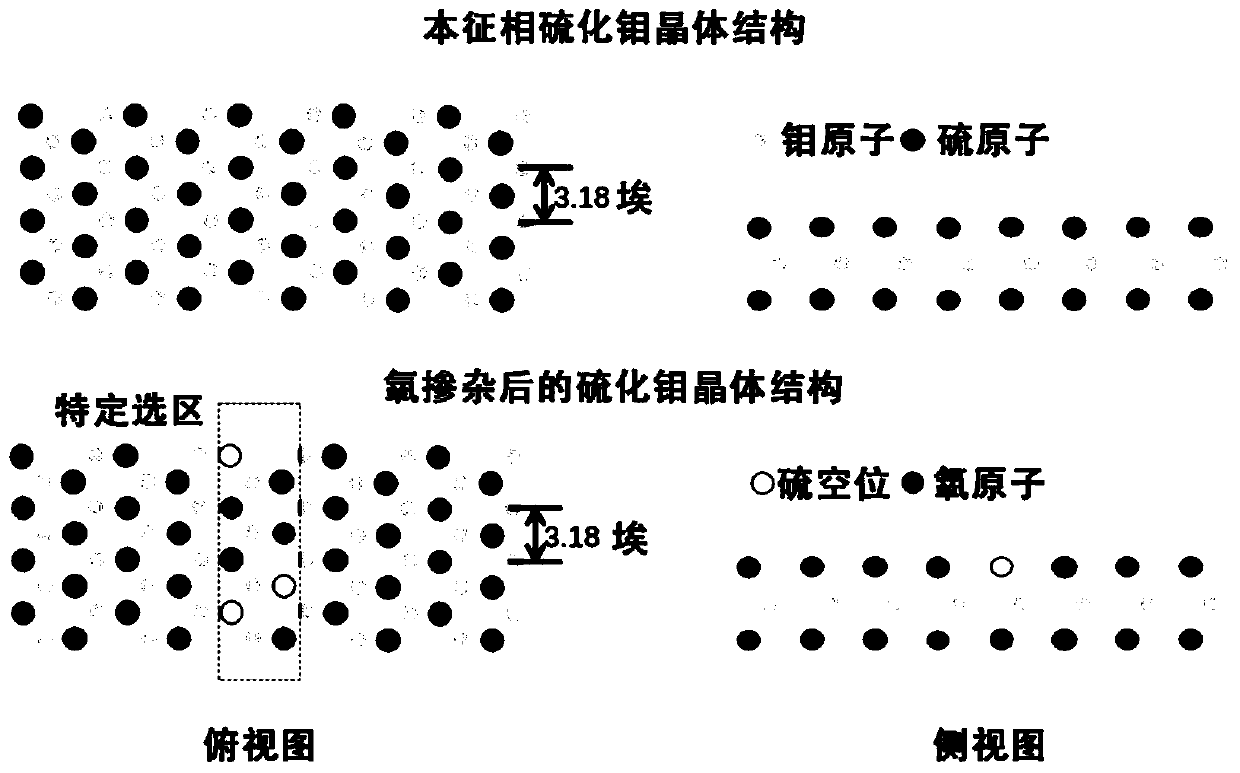

[0062] (1) Mechanically exfoliated MoS 2 2D material transfer to SiO 2 / Si substrate, then with the MoS 2 The substrate of the two-dimensional material is placed on the stage of the laser direct writing system (laser direct writing lithography machine), and the CCD camera is used in conjunction with the moving system of the stage (moving accuracy is 10nm) to find the area to be modified.

[0063] (2) Use the laser direct writing system to carry out laser direct writing in the air according to the set grayscale image in the region to be modified in step (1), set the laser pulse width of the laser direct writing to be 10 ns, and the laser power As the grayscale becomes larger, it increases linearly, 0 grayscale 0 power output, 255 grayscale 100mW power output, and oxygen-doped modified MoS is obtained. 2 2D materials;

[0064] Where...

Embodiment 2

[0072] This embodiment provides a method for oxygen doping modification of two-dimensional materials. Referring to Embodiment 1, the difference is that in this embodiment, the two-dimensional material in step (1) is WSe obtained by chemical vapor deposition. 2 The grayscale image of step (2) is an isosceles right-angled triangle, the grayscale at the apex of the right angle is 0, and the grayscale at the hypotenuse is 255. The grayscale of the grayscale image changes gradually from the apex to the hypotenuse, gradually increasing Large; set the laser pulse width of laser direct writing to 1000ns, the laser power changes linearly with the increase of the gray scale, the power output of 0 gray scale is 36mW, and the power output of 255 gray scale is 80mW. Other specific conditions and parameters are the same as in Example 1.

[0073] In this example, the obtained modified WSe 2 The oxygen-doped modification area of the two-dimensional material is an isosceles right-angled tri...

Embodiment 3

[0075] In this embodiment, the black solid-color rectangular pattern with the same shape and size as the oxygen-doped writing pattern is used instead of the grayscale image, and other specific conditions and parameters are the same as in the embodiment 1.

[0076] In this example, the obtained modified MoS 2 The oxygen-doped modified area of the two-dimensional material is rectangular, and the oxygen-doped content is the same at all points in the doped area, which is the doping of the product in Example 1 corresponding to the position where the gray scale of the grayscale image in Example 1 is 255. The oxygen doping content of the position is the same. The accuracy of the doping position in this embodiment reaches 100 nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com