Porcelain algae silicon composite material and preparation method thereof

A silicon composite material and porcelain technology, applied in the field of porcelain algal silica composite material and its preparation, can solve the problems of high overall density, poor air permeability, lack of adsorption of harmful gases, etc., and achieve the effect of smooth and clean surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

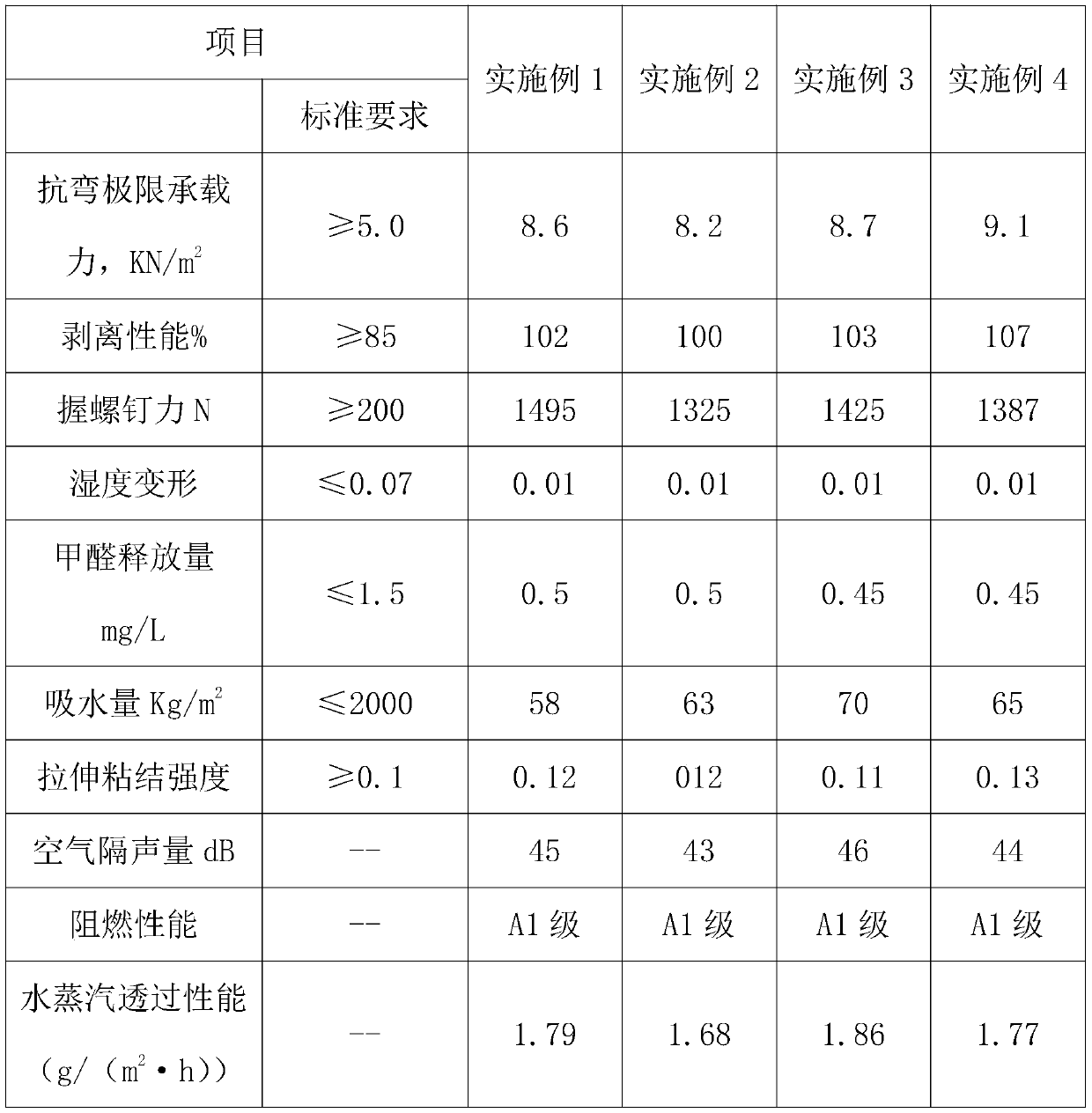

Examples

Embodiment 1

[0039] A porcelain algae silica composite material, comprising in parts by weight:

[0040] Kaolin 25Kg, diatomite 40Kg, cement 30Kg, silica fume 7Kg, basalt fiber 4Kg, magnesium oxide 10Kg, magnesium sulfate 20Kg, bamboo powder 40Kg, condensate fluid 1Kg.

[0041] A preparation method of porcelain algae silica composite material, comprising the steps of:

[0042] Step 1. Weigh the raw materials of each component according to the formula of the porcelain algae-silicon composite material for later use;

[0043] Step 2, premix the bamboo powder and cement evenly, then add magnesium oxide, magnesium sulfate, basalt fiber and silica fume to mix evenly for the second time, and finally add kaolin, diatomaceous earth and a small amount of water to mix evenly to obtain a mixed dry material;

[0044] Step 3. Add diatomite and kaolin to the high-speed mixer and mix at a speed of 1400-1500rpm for 5-15 minutes, so that the temperature of diatomite and kaolin in the high-speed mixer reach...

Embodiment 2

[0047] A kind of porcelain algae silicon composite material, comprises by weight Kg:

[0048] Kaolin 10Kg, diatomite 20Kg, cement 20Kg, silica fume 6Kg, basalt fiber 3Kg, magnesium oxide 5Kg, magnesium sulfate 10Kg, bamboo powder 30Kg, condensate fluid 1Kg.

[0049] The preparation method of the composite material of Example 2 is the same as that of Example 1.

Embodiment 3

[0051] A kind of porcelain algae silicon composite material, comprises by weight Kg:

[0052] Kaolin 50Kg, diatomite 60Kg, cement 20Kg, silica fume 10Kg, basalt fiber 6Kg, magnesium oxide 20Kg, magnesium sulfate 40Kg, bamboo powder 70Kg, condensate fluid 2Kg.

[0053] The preparation method of the composite material of embodiment 3 is the same as that of embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com