Preparation method of alginate/polyacrylamide composite hydrogel with wrinkled surface

A composite hydrogel and polyacrylamide technology, which is applied in diagnostic recording/measurement, instrumentation, diagnosis, etc., can solve the problems of not suitable for large-scale preparation, complex 3D printing equipment, high preparation cost, etc., and achieve the goal of increasing the area Effect of changing, improving mechanical strength and modulus, and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

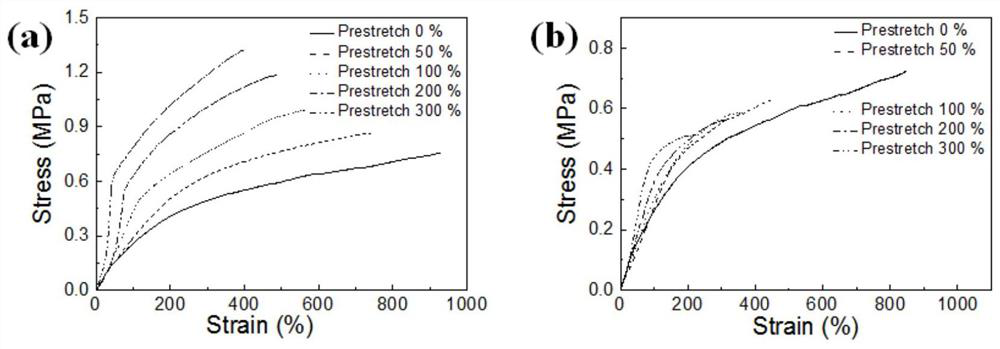

[0035] (1) Dissolve 0.75g of alginate, 6g of acrylamide, 4mg of N,N-methylenebisacrylamide and 0.078g of calcium sulfate dihydrate in 35ml of water, stir and remove air bubbles, and then add 50mg / mL of persulfuric acid 5 ml of ammonium aqueous solution was stirred and mixed, and nitrogen gas was passed through to remove dissolved oxygen. Then, the mixture was injection molded and sealed, and placed in an oven at 70°C for reaction. Finally, the prepared hydrogel was removed from the mold.

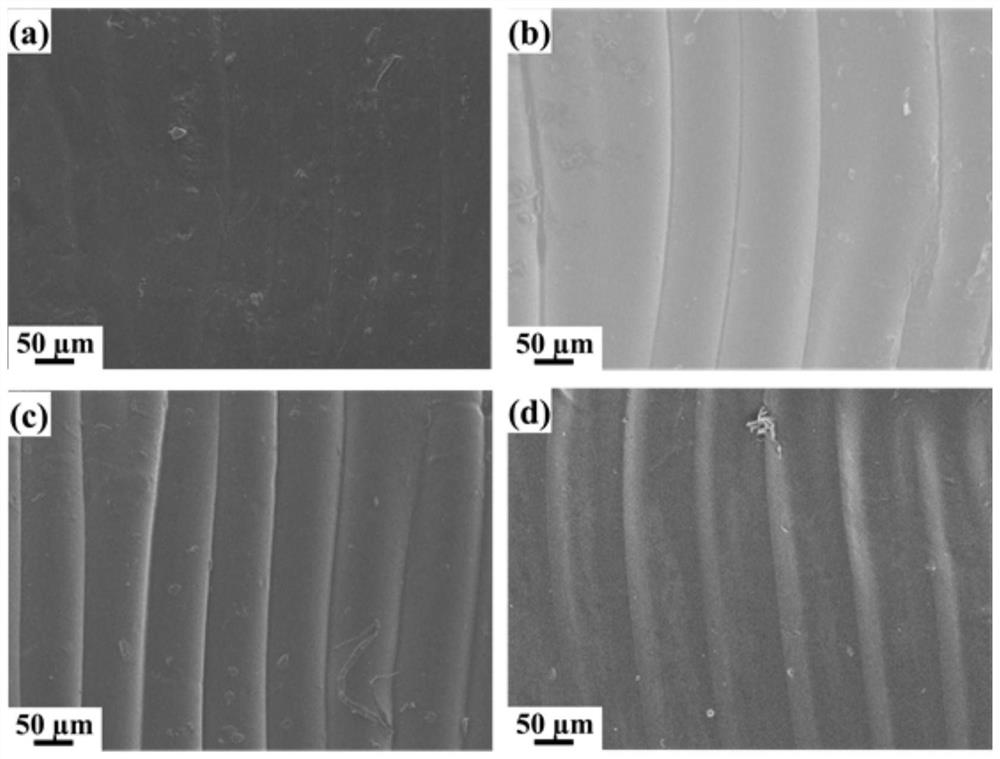

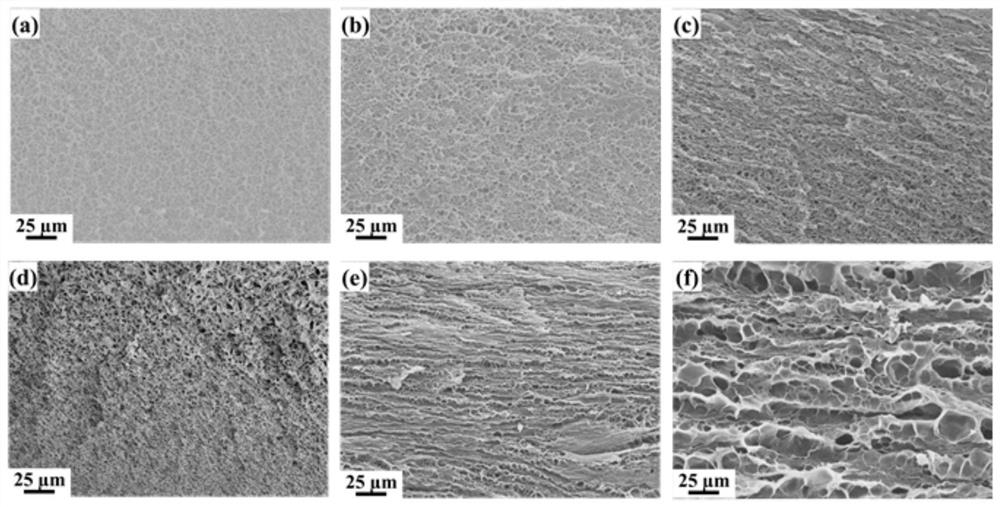

[0036] (2) Take the hydrogel prepared in (1) and cut it into a cuboid of 20*5*2mm, and carry out different degrees of pre-stretching on it, and the amount of pre-stretching is 50%, 100%, 200% and 300% respectively ;

[0037] (3) The hydrogels with different pre-stretching were soaked in 2.7mg / mL ferric chloride hexahydrate aqueous solution for 0.5min, 3min, 30min and 180min. Release the pulling force after soaking, and finally wash off excess ions with deionized water.

[0038] (4) A die...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com