Ceramic white bleeding ink and preparation method thereof, ceramic tile and preparation method thereof

A ceramic tile and white technology, applied in the field of ceramic material preparation, can solve problems such as blocked nozzles, poor color rendering, and delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

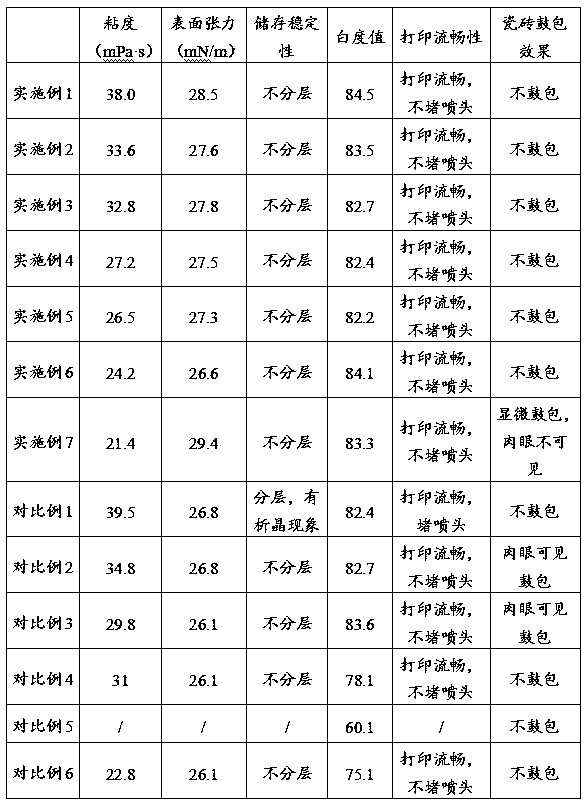

Examples

Embodiment 1

[0063] The preparation method of ceramic white bleed flower ink comprises the following steps:

[0064] (1) NaOH and isooctanoic acid were used as raw materials, the temperature was controlled at 80°C, and the reaction time was 5 hours, and sodium isooctanoate was prepared through acid-base saponification;

[0065] (2) Prepare the sodium isooctanoate obtained in step (1) into a solution with a mass fraction of 10%, and add 42% metal salt solution and isopropyl myristate solvent, and mix well;

[0066] (3) After the reaction in the above step (2), the organic phase was obtained by extraction and liquid separation, and the moisture in the organic phase was removed by vacuum distillation at a temperature of 128° C. to obtain a chromogenic organic isooctanoic acid metal salt;

[0067] (4) According to mass percentage, 1% BYK110, 50% metal salt of chromogenic organic isooctanoate (among them, 23% of cerium isooctanoate, 76% of zirconium isooctanoate, 1% of aluminum isooctanoate) an...

Embodiment 2

[0075] The preparation method of ceramic white bleed flower ink comprises the following steps:

[0076] (1) Using NaOH and organic carboxylic acid as raw materials, the temperature is controlled at 60°C, and the reaction time is 10h, and sodium isooctanoate is prepared through acid-base saponification;

[0077] (2) The sodium organic carboxylate obtained in the step (1) is formulated into a solution with a mass fraction of 17%, and 26% of the water-soluble metal salt solution and isopropyl palmitate solvent are added, and mixed uniformly;

[0078](3) After the reaction in the above step (2), the organic phase is obtained by extraction and liquid separation, and the moisture in the organic phase is removed by vacuum distillation at a temperature of 150° C. to obtain a chromogenic organic organic carboxylate metal salt;

[0079] (4) According to mass percentage, 1% BYK111, 50% metal salt of chromogenic organic carboxylic acid (among them, 25% cerium isooctanoate, 69.9% zirconium...

Embodiment 3

[0086] The preparation method of ceramic white bleed flower ink comprises the following steps:

[0087] (1) Using NaOH and organic carboxylic acid as raw materials, the temperature is controlled at 60°C, and the reaction time is 10h, and sodium isooctanoate is prepared through acid-base saponification;

[0088] (2) The sodium organic carboxylate obtained in the step (1) is formulated into a solution with a mass fraction of 17%, and 26% of the water-soluble metal salt solution and isopropyl palmitate solvent are added, and mixed uniformly;

[0089] (3) After the reaction in the above step (2), the organic phase is obtained by extraction and liquid separation, and the moisture in the organic phase is removed by vacuum distillation at a temperature of 150° C. to obtain a chromogenic organic organic carboxylate metal salt;

[0090] (4) According to mass percentage, 3.8% BYK111, 40% metal salt of chromogenic organic carboxylic acid (among them, 25% cerium isooctanoate, 67% zirconiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com