Composite rubber film used for complex shape surface multi-pas laser shock reinforcement

A laser shock strengthening, complex shape technology, applied in the direction of film/sheet adhesives, adhesives, etc., can solve the problems of increasing cost, reducing the efficiency of laser shock strengthening, etc., to achieve strong resistance to vaporization, a wide range of engineering applications, The effect of engineering application cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] In engineering practice, when the surface of the part is designed or the surface of the planar part is notched due to corrosion and other reasons to form a curved surface, which requires laser shock strengthening, the surface of the target is a complex curved surface. The surface of the target 4 of the present invention can be any complex curved shape, Figure 10 Shown are several basic complex surface shapes, including basic shape elements: convex cylindrical surface, concave cylindrical surface, biconvex curved surface, biconcave curved surface, convex-concave (saddle-shaped) curved surface, etc.

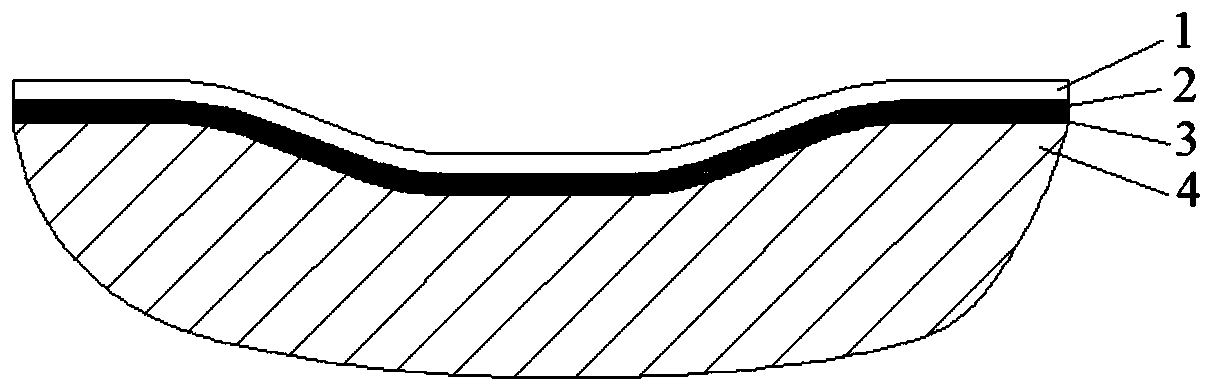

[0041] Such as figure 1 As shown, a composite adhesive film for multi-pass laser shock strengthening on complex-shaped surfaces is composed of an energy-absorbing layer and an energy-constraining layer; The film consists of two layers of materials, which are connected by black electrical tape 2 and black double-sided tape 3; the energy-constrained layer is a transparent co...

Embodiment 2

[0051] Such as figure 2 As shown, the material of the transparent constrained layer in this embodiment is E-42 double atmosphere A-type epoxy resin and YS-1618 alicyclic amine curing agent according to the formula of 1.5:1 mass ratio, and the material of the transparent constrained layer is made of silica gel mold The 2.2 mm thick transparent constrained layer is kept at 100°C for 30 minutes, and the transparent constrained layer is in a semi-cured state at this time.

[0052] During the waiting period for the semi-curing of the constrained layer material, the image 3 A commercially available black electrical tape as shown is applied to the Figure 10 On the complex surface target shown in (B), and then Figure 4 Commercially available black double-sided tape shown affixed to black electrical tape. Then paste the semi-cured transparent constraining layer on the black double-sided tape, and then continue to heat it with a hair dryer at about 60°C for 25 minutes to obtain a...

Embodiment 3

[0054] Such as figure 2 As shown, the material of the transparent constrained layer in this embodiment is obtained by blending EX-20 double atmosphere A-type epoxy resin and WZH-155 alicyclic amine curing agent at a mass ratio of 1.5:1, and the material of the transparent constrained layer is made of a silica gel mold of 2.1 The transparent constrained layer with a thickness of mm is kept at 100°C for 35 minutes, and the transparent constrained layer is in a semi-cured state at this time.

[0055] During the waiting period for the semi-curing of the constrained layer material, the image 3 A commercially available black electrical tape as shown is applied to the Figure 10 On the complex surface target shown in (D), the Figure 4 Commercially available black double-sided tape shown affixed to black electrical tape. Then paste the semi-cured transparent constraining layer on the black double-sided tape, and then continue to heat it with a hair dryer at about 60°C for 20 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com