Low-temperature production process for corrugated paper board

A corrugated cardboard and production process technology, applied in the direction of mechanical processing/deformation, adhesive type, adhesive additives, etc., can solve the problems of paper fiber damage, paper fiber is easily damaged, and cardboard quality is poor, so as to reduce Effect of temperature and air pressure, improvement of low temperature resistance, and reduction of gluing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The invention relates to a low-temperature production process of corrugated cardboard, including corrugation, glue making, gluing paper, drying and shaping, glue making: preparing an adhesive, and the adhesive includes the following components in parts by weight: 100-135 parts of starch, 300-450 parts of solvent water, 5-7 parts of 30% caustic soda solution, 10-19 parts of 10% caustic soda solution, 5-26 parts of 10% borax solution, 0.7-1.2 parts of stabilizer, 2.4-3.3 part low-temperature additive; the stabilizer includes the following components in weight percentage: polyvinyl formal 55%-75%, hydroxyethyl cellulose 25%-45%; the low-temperature additive includes the following components in weight percentage: 40%-55% polyvinyl alcohol, 30%-40% urea-formaldehyde resin, 5-15% light calcium carbonate, 3-10% other resins; corn starch or tapioca starch is used as starch; the temperature for making glue is 35-40°C;

[0026] Laminated paper: After the corrugated core paper is ...

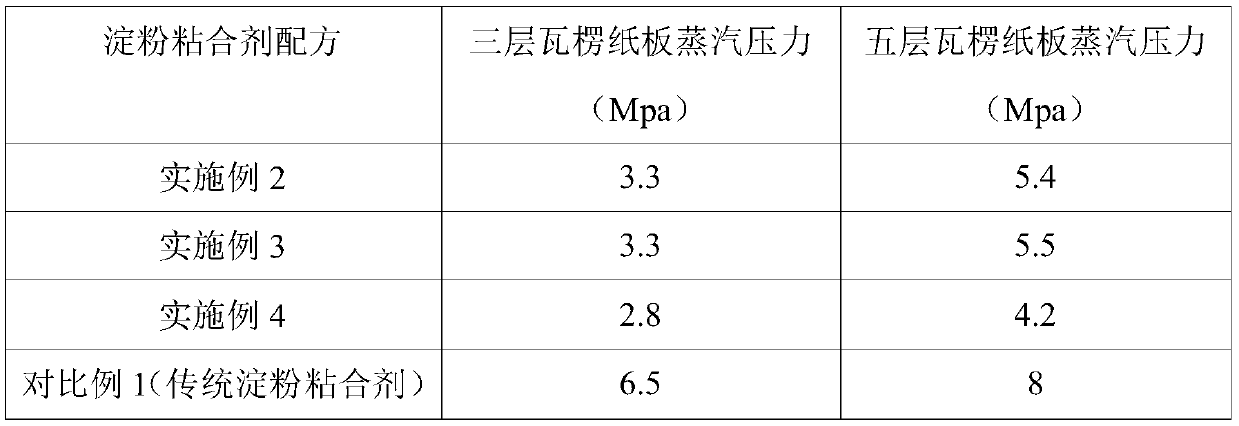

Embodiment 2

[0030] Based on the above examples, the adhesive includes the following components in parts by weight: 100 parts of starch, 300 parts of solvent water, 5 parts of 30% caustic soda, 10 parts of 10% caustic soda, 5 parts of 10% caustic soda Borax solution, 0.7 parts of stabilizing agent, 2.4 parts of low-temperature additive; Described stabilizing agent comprises the component of following percentage by weight: polyvinyl formal 68%, hydroxyethyl cellulose 35%; Described low-temperature additive comprises following weight percentage Components: polyvinyl alcohol 52%, urea-formaldehyde resin 35%, light calcium carbonate 12%, other resin 6%. In this example, the adhesive has very good viscosity stability when the temperature is above 10°C, and it does not precipitate when placed. When the temperature is as low as 2°C-10°C, it is stored for 24 hours and can quickly recover to the initial viscosity and performance of the finished product with only short stirring.

Embodiment 3

[0032] Based on the above examples, the low-temperature paper starch adhesive includes the following components in parts by weight: 135 parts of starch, 450 parts of solvent water, 7 parts of 30% caustic soda, 19 parts of 10% caustic soda solution, 26 parts of borax solutions with a concentration of 10%, 1.2 parts of stabilizers, and 3.3 parts of low-temperature additives; the stabilizers include the following components in percentage by weight: polyvinyl formal 68%, hydroxyethyl cellulose 35%; The low-temperature additive includes the following components in weight percentage: 52% of polyvinyl alcohol, 35% of urea-formaldehyde resin, 12% of light calcium carbonate, and 6% of other resins. In this example, the adhesive has very good viscosity stability when the temperature is above 10°C, and it does not precipitate when placed. When the temperature is as low as 2°C-10°C, it is stored for 24 hours and can quickly recover to the initial viscosity and performance of the finished p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com