Low-temperature starch adhesive for paper products and preparation method thereof

A starch adhesive and low temperature technology, applied in the direction of starch adhesive, adhesive type, polymer adhesive additive, etc., can solve the problems of poor cardboard quality, unstable performance, and easy damage of paper fibers , to achieve excellent viscosity stability, improve water resistance, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The low-temperature paper product starch adhesive of the present invention comprises the following components: starch, solvent water, lye, borax solution, stabilizer, low-temperature additive, starch and solvent water are mixed to prepare starch slurry.

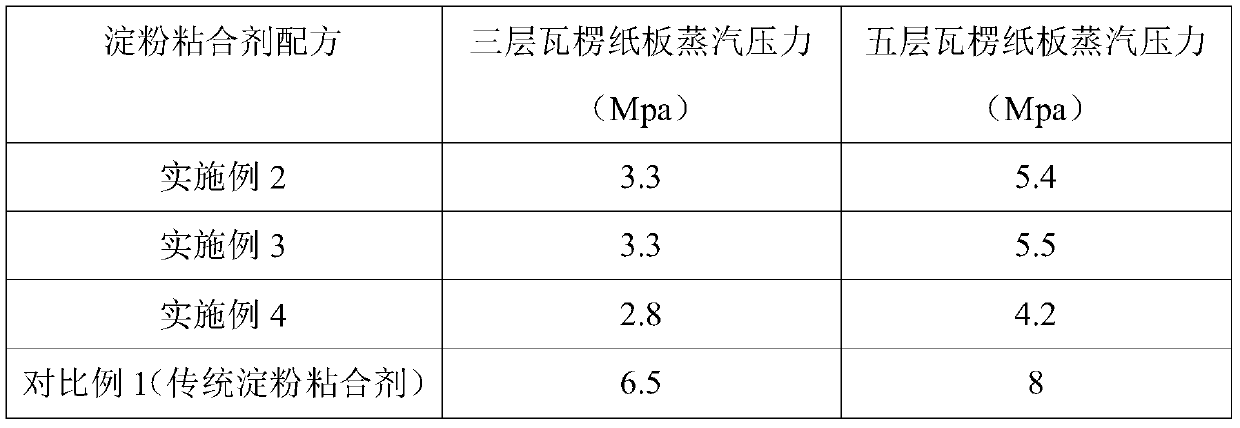

[0032] The present invention changes and improves the low temperature resistance of the adhesive by adding low temperature additives and stabilizers to the starch adhesive, thereby reducing the temperature and air pressure of the cardboard production line, and the produced cardboard has a very strong Moisture resistance, burst resistance, water resistance, and bonding strength are significantly better than national standards.

Embodiment 2

[0034] Based on Example 1, the low-temperature paper product starch binder includes the following components in parts by weight: 100 parts of starch, 300 parts of solvent water, 5 parts of 30% caustic soda, 10 parts of 10% caustic soda Solution, 5 parts of 10% borax solution, 0.7 parts of stabilizer, 2.4 parts of low temperature additive. The stabilizer comprises the following components by weight percentage: polyvinyl formal 55%-75%, hydroxyethyl cellulose 25%-45%. The low-temperature additive includes the following components in weight percentage: 40%-55% of polyvinyl alcohol, 30%-40% of urea-formaldehyde resin, 5-15% of light calcium carbonate, and 3-10% of other resins. The influence of borax on the adhesive index cannot be measured by instruments. It can only be adjusted according to the bonding effect of corrugated cardboard. Moreover, the air humidity changes in the climate, and the amount of borax needs to be adjusted accordingly. The adjustment range depends on the st...

Embodiment 3

[0036] Based on Example 1, the low-temperature paper product starch adhesive includes the following components in parts by weight: 135 parts of starch, 450 parts of solvent water, 7 parts of 30% caustic soda, 19 parts of 10% caustic soda solution, 26 parts of 10% borax solution, 1.2 parts of stabilizer, and 3.3 parts of low-temperature additive. The stabilizer comprises the following components by weight percentage: polyvinyl formal 55%-75%, hydroxyethyl cellulose 25%-45%. The low-temperature additive includes the following components in weight percentage: 40%-55% of polyvinyl alcohol, 30%-40% of urea-formaldehyde resin, 5-15% of light calcium carbonate, and 3-10% of other resins. In this example, the adhesive has very good viscosity stability when the temperature is above 10°C, and it does not precipitate when placed. When the temperature is as low as 2°C-10°C, it is stored for 24 hours and can quickly recover to the initial viscosity and performance of the finished product w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com