Starch adhesive suitable for high-speed corrugated paper board production line and preparation method of starch adhesive

A technology for starch adhesives and corrugated cardboard, applied in the direction of starch adhesives, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problem of long heating and drying time, low paper feeding speed, The problem of high raw material cost can save the amount of glue, improve the compressive strength and lower the gelatinization temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

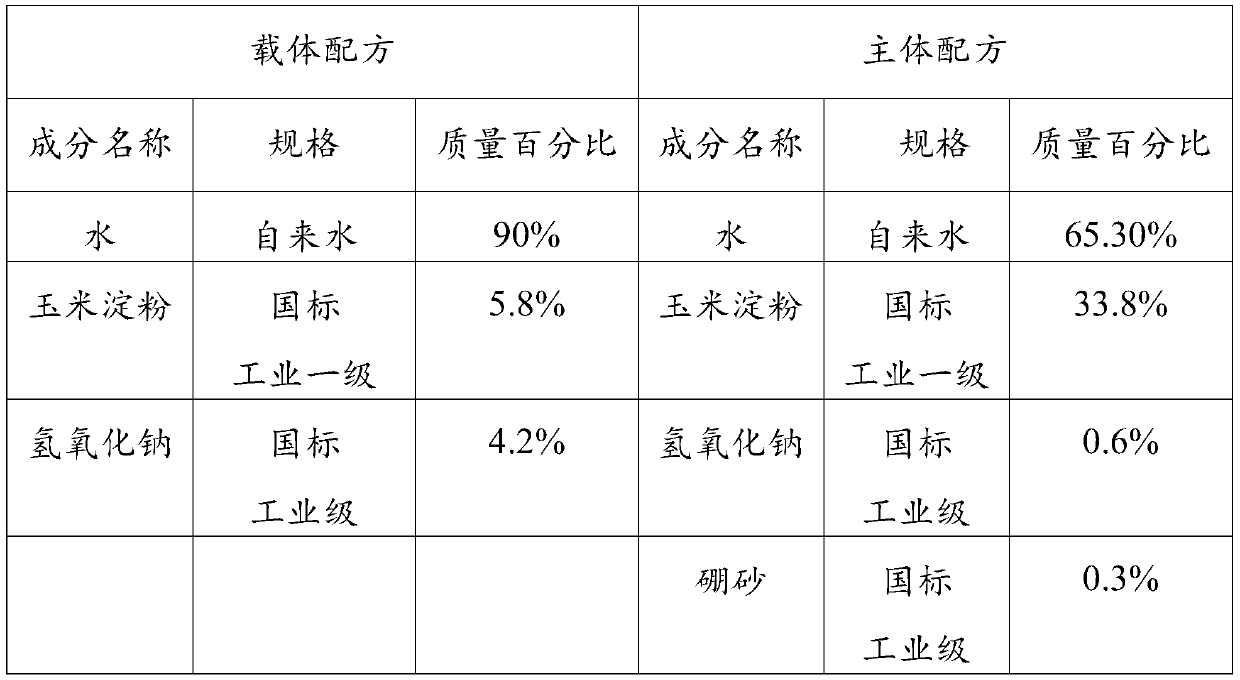

[0031] A starch adhesive suitable for a high-speed corrugated board production line, consisting of the following raw materials and their mass fractions:

[0032]

[0033]

[0034] A kind of preparation method that is applicable to the starch adhesive of high-speed corrugated cardboard production line, comprises the steps:

[0035] The first step, the preparation of carrier starch:

[0036] A. Add measured water into the carrier reaction tank and heat to 35°C;

[0037] B, continue to add cornstarch in the carrier reaction tank, stir by the frequency conversion turbine stirring impeller, the stirring speed is 500~1000 rpm, and the stirring time is 500 seconds;

[0038] C, after sodium hydroxide is dissolved in water, obtain the sodium hydroxide solution that concentration is 99.0%, add in the carrier reaction tank three times and stir, stirring speed is 1000~1500 rev / min, and stirring time is 500 seconds, thus obtains Starch paste gelatinized under alkaline conditions; ...

Embodiment 2

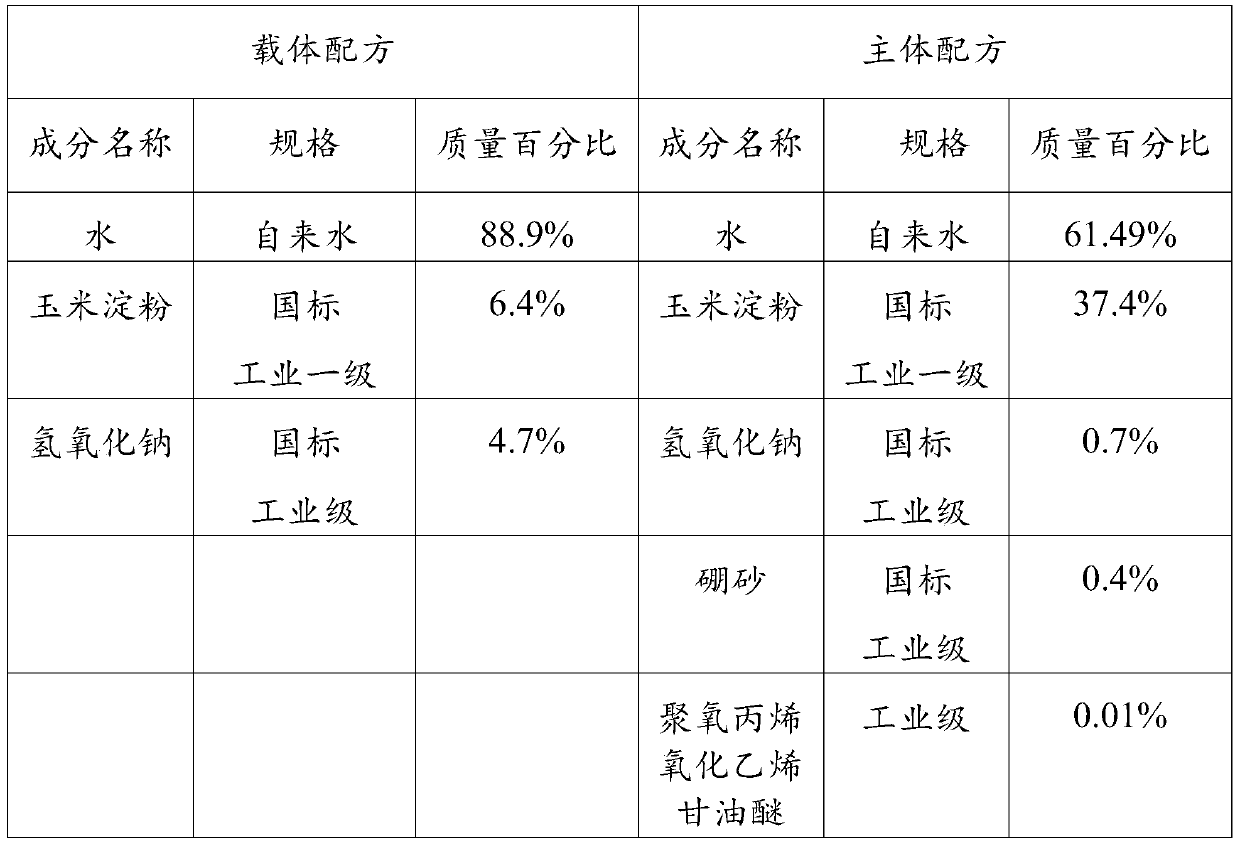

[0049] A starch adhesive suitable for a high-speed corrugated board production line, consisting of the following raw materials and their mass fractions:

[0050]

[0051] A kind of preparation method that is applicable to the starch adhesive of high-speed corrugated cardboard production line, comprises the steps:

[0052] The first step, the preparation of carrier starch:

[0053] A. Add measured water into the carrier reaction tank and heat to 40°C;

[0054] B, continue to add cornstarch in the carrier reaction tank, stir by the frequency conversion turbine stirring impeller, the stirring speed is 500~1000 rpm, and the stirring time is 500 seconds;

[0055] C, after sodium hydroxide is dissolved in water, obtain the sodium hydroxide solution that concentration is 99.0%, add in the carrier reaction tank three times and stir, stirring speed is 1000~1500 rev / min, and stirring time is 500 seconds, thus obtains Starch paste gelatinized under alkaline conditions;

[0056] Sec...

Embodiment 3

[0066] A starch adhesive suitable for a high-speed corrugated board production line, consisting of the following raw materials and their mass fractions:

[0067]

[0068] A kind of preparation method that is applicable to the starch adhesive of high-speed corrugated cardboard production line, comprises the steps:

[0069] The first step, the preparation of carrier starch:

[0070] A. Add measured water into the carrier reaction tank and heat to 38°C;

[0071] B, continue to add cornstarch in the carrier reaction tank, stir by the frequency conversion turbine stirring impeller, the stirring speed is 500~1000 rpm, and the stirring time is 500 seconds;

[0072] C, after sodium hydroxide is dissolved in water, obtain the sodium hydroxide solution that concentration is 99.0%, add in the carrier reaction tank three times and stir, stirring speed is 1000~1500 rev / min, and stirring time is 500 seconds, thus obtains Starch paste gelatinized under alkaline conditions;

[0073] Sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com