Remediation reagent for mine soil contaminated with heavy metal lead and use method of remediation reagent

A soil remediation and lead pollution technology, applied in the field of environmental governance, can solve the problems of non-absorption, damage of soil acid-base balance, increase of soil remediation cost, etc., and achieve the effect of facilitating plant planting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

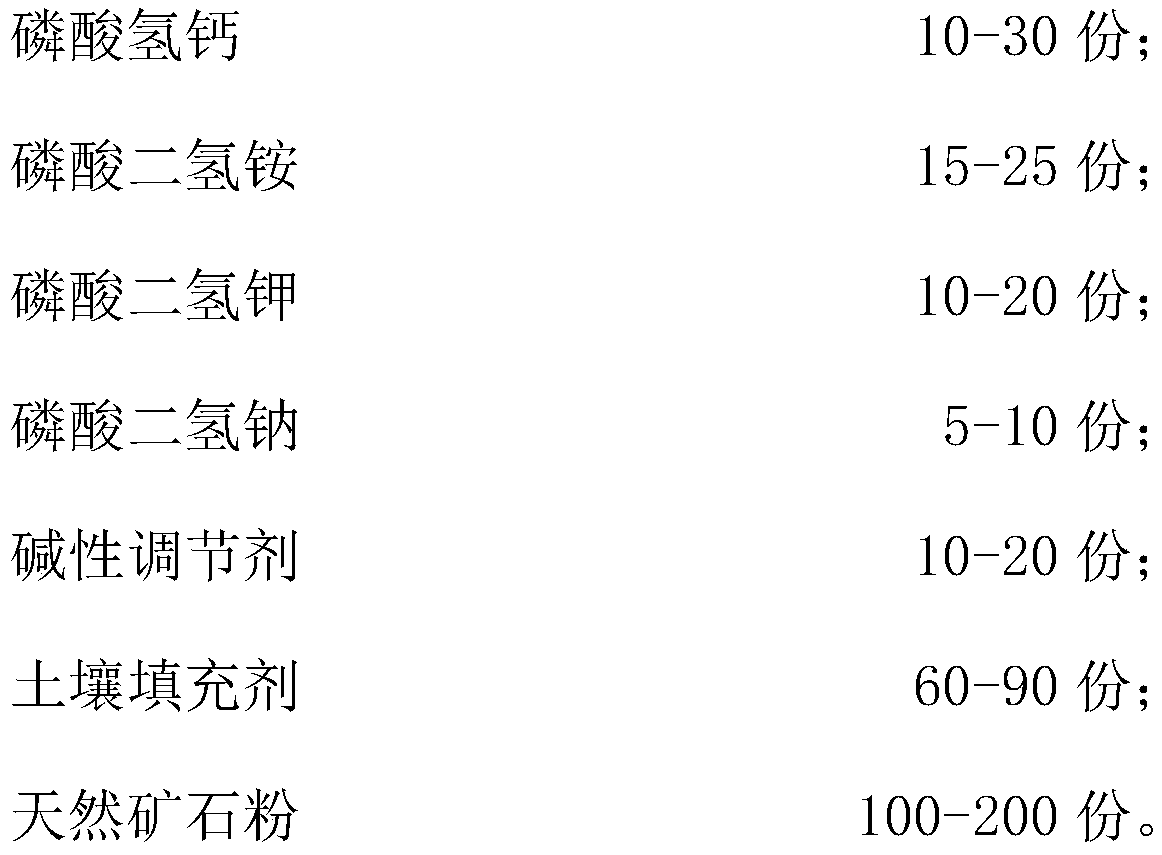

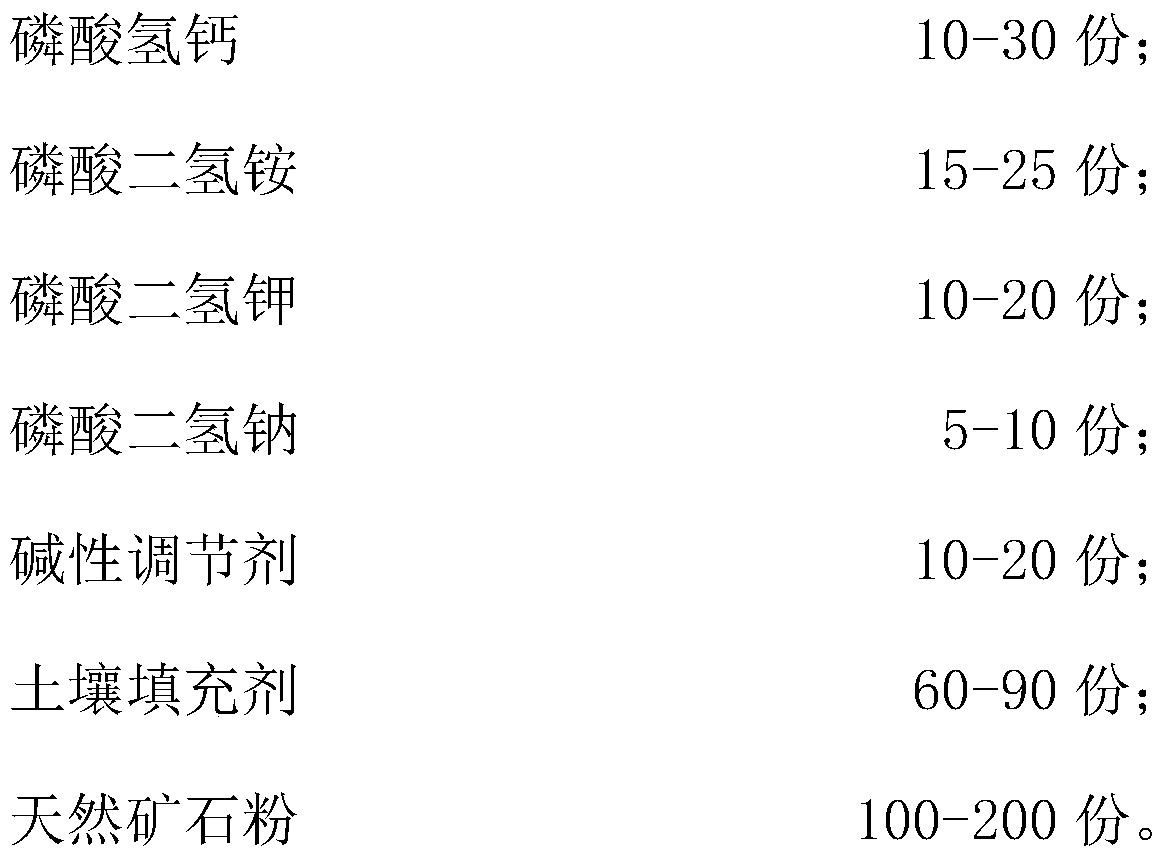

Embodiment 1

[0020] Step 1: Weigh 10g calcium hydrogen phosphate, 15g ammonium dihydrogen phosphate, 10g potassium dihydrogen phosphate, 5g sodium dihydrogen phosphate, 10g alkaline conditioner, 60g soil filler, 100g natural ore powder, mix, pulverize, and set aside;

[0021] Step 2: fully mix the powder in step 1 with the soil contaminated by metal lead according to the ratio of 1:7, and place it in the external environment;

[0022] Step 3: Observe and record the content of free lead ions in samples every three days.

Embodiment 2

[0024] Step 1: Weigh 30g calcium hydrogen phosphate, 25g ammonium dihydrogen phosphate, 20g potassium dihydrogen phosphate, 10g sodium dihydrogen phosphate, 20g alkaline conditioner, 90g soil filler, 200g natural ore powder, mix, pulverize, and set aside;

[0025] Step 2: fully mix the powder in step 1 with the soil contaminated by metal lead according to the ratio of 1:12, and place it in the external environment;

[0026] Step 3: Observe and record the content of free lead ions in samples every three days.

Embodiment 3

[0028] Step 1: Weigh 20g calcium hydrogen phosphate, 20g ammonium dihydrogen phosphate, 15g potassium dihydrogen phosphate, 7.5g sodium dihydrogen phosphate, 15g alkaline conditioner, 75g soil filler, 150g natural ore powder, mix, crush and set aside ;

[0029] Step 2: fully mix the powder in step 1 with the soil contaminated by metal lead according to the ratio of 1:9, and place it in the external environment;

[0030] Step 3: Observe and record the content of free lead ions in samples every three days.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com