Thin size high-strength steel for engineering machinery and strip shape control method

A technology for construction machinery and high-strength steel plates, applied in the field of high-strength steel manufacturing, can solve the problems of high strength and elongation margin, high content of precious metal Mo, and push up production costs, etc., to achieve a cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

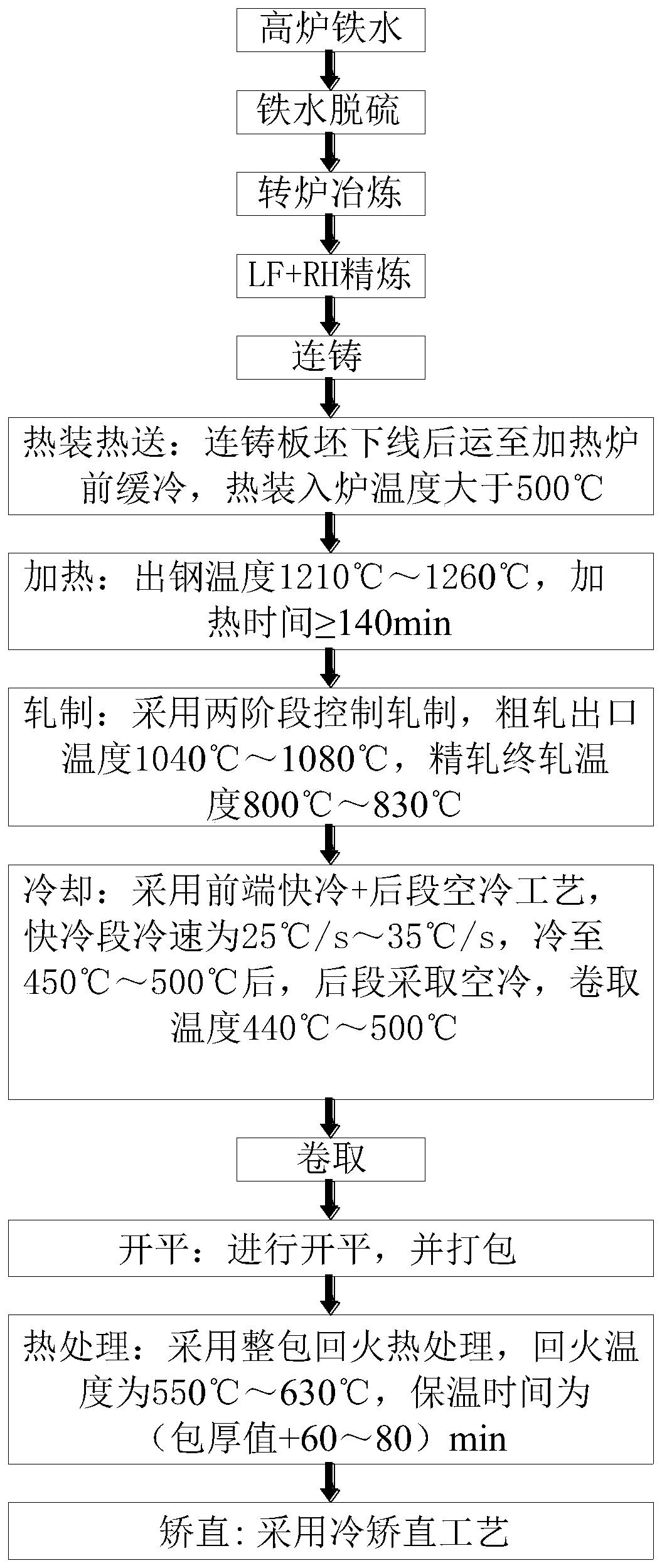

Method used

Image

Examples

Embodiment 1~3

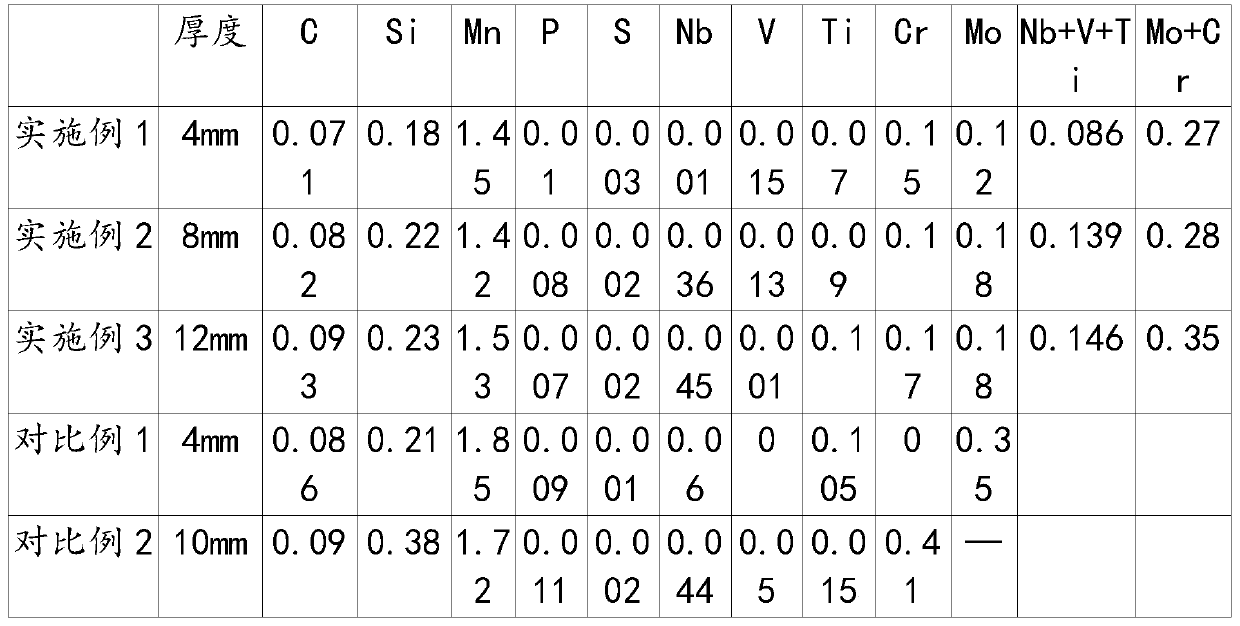

[0057] Examples 1-3, a high-strength steel for thin-gauge construction machinery, the specific chemical components and their weight percentages are shown in Table 1; Comparative Examples 1-2, the chemical components and their weight percentages are also shown in Table 1:

[0058] Table 1

[0059]

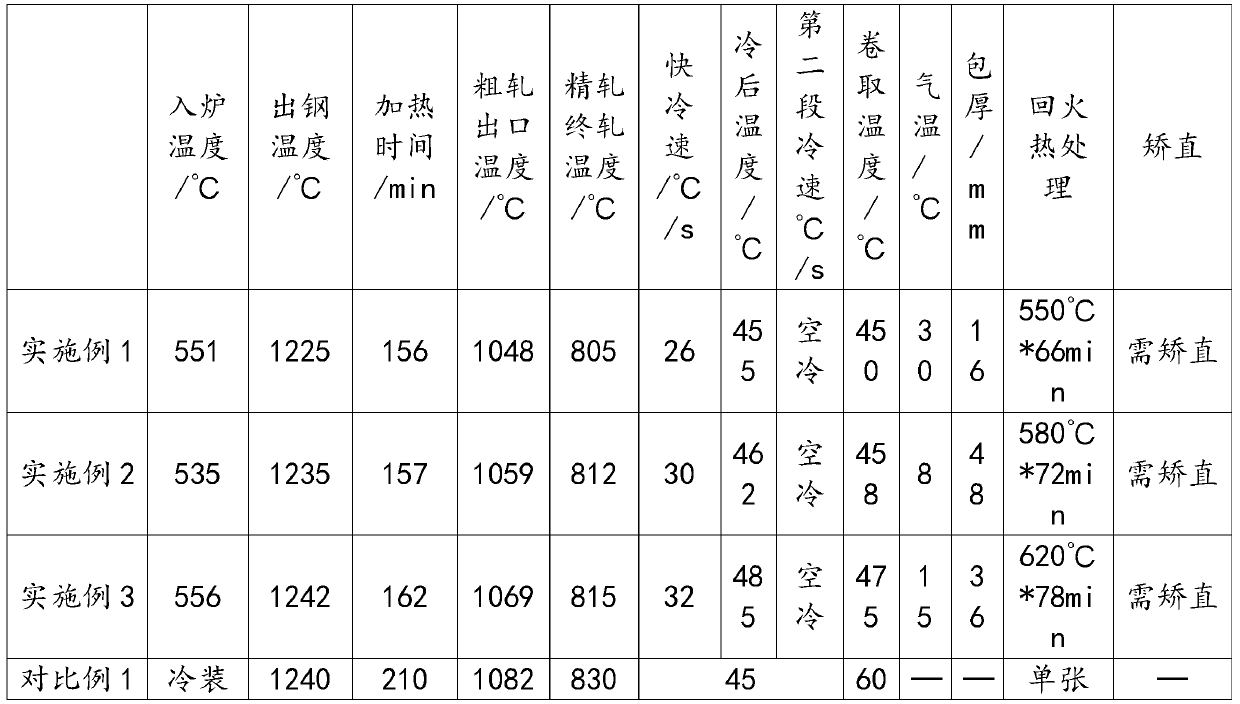

[0060] The concrete process data of production process feature among embodiment 1-3 and comparative example 1-2 is shown in Table 2:

[0061] Table 2

[0062]

[0063]

[0064] According to national standards GB / T228 and GB / T231, the properties of the thin-gauge high-strength engineering machinery steels described in Examples 1-3 and Comparative Examples 1-2 are shown in Table 3.

[0065] table 3

[0066]

[0067]

[0068] It can be seen that under the three processes of the example, the yield strength is above 690MPa, the tensile strength is above 790MPa, the A50 is above 21%, the low temperature toughness at -20°C is excellent, the transverse and longitudinal cold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com