A Quenching Device for Large Forged Fan Spindle

A large-scale forging and quenching device technology, applied in the direction of quenching devices, furnace types, furnaces, etc., can solve problems such as poor quenching, inability to improve toughness, and inability to pursue the quenching effect alone, so as to improve the quenching effect and increase the depth of the hardened layer , the effect of improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

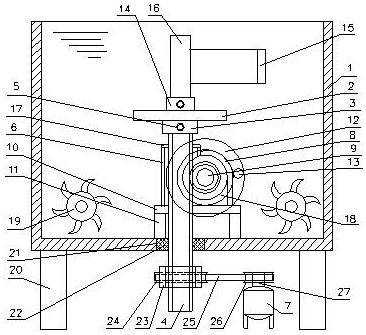

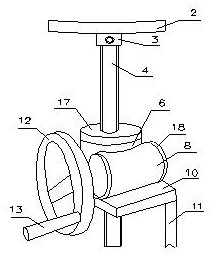

[0015] A quenching device for a fan spindle for large-scale forgings, comprising: a sample tank 1, a rotating platform 2 is arranged in the sample tank, the rotating platform is fixedly connected to a circular sleeve 3, and the circular sleeve is connected to a lifting screw 4. The round sleeve and the lifting screw are fixed by screws 5, the lifting screw is installed in the housing 6, the bottom of the lifting screw is connected to the transmission device, and the transmission device is connected to the motor 7, The housing is fixedly connected to the sub-housing 8, the sub-housing is equipped with a horizontal screw 9, the horizontal screw engages the lifting screw, and the housing is connected to the sub-housing The base plate 10, the base plate is connected to the support leg 11, the horizontal screw rod is connected to the control panel 12, the control panel is connected to the handle 13, the rotating platform is connected to the fixed sleeve 14, the fixed sleeve is conne...

Embodiment 2

[0017] A quenching device for a large-scale forging blower fan spindle described in Example 1, the housing is connected to the sealing cover 17, the auxiliary housing is connected to the auxiliary sealing cover 18, and maple leaves are arranged around the sample tank. Stirrer 19, the maple leaf stirrer is distributed around the lifting screw, the bottom of the maple leaf stirrer is fixed on the bottom of the sample tank, and the bottom of the sample tank is connected to the total support leg 20.

Embodiment 3

[0019] In the quenching device for a fan spindle for a large forging fan described in Example 2, a through hole 21 is opened at the bottom of the sample tank, and the lifting screw passes through the through hole, and the through hole is connected to the through hole. A sealing ring 22 is installed between the lifting screws, the lifting screw is connected to the threaded sleeve 23, the threaded sleeve is fixedly connected to the pulley 24, the pulley is connected to the belt 25, and the belt is connected to the main pulley 26. The output shaft 27 of the primary pulley connected motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com