Vehicle air conditioner and heat pump integrated system

A vehicle air conditioner and heat pump technology, which is applied to vehicle parts, refrigeration and liquefaction, and air treatment equipment, etc., can solve the problems of large filling capacity, air leakage and heat leakage, and occupy a lot of space, so as to reduce the risk of safe driving accidents , The effect of reducing the pressure on the high pressure side and uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Embodiment 1. Vehicle air-conditioning heat pump integrated system

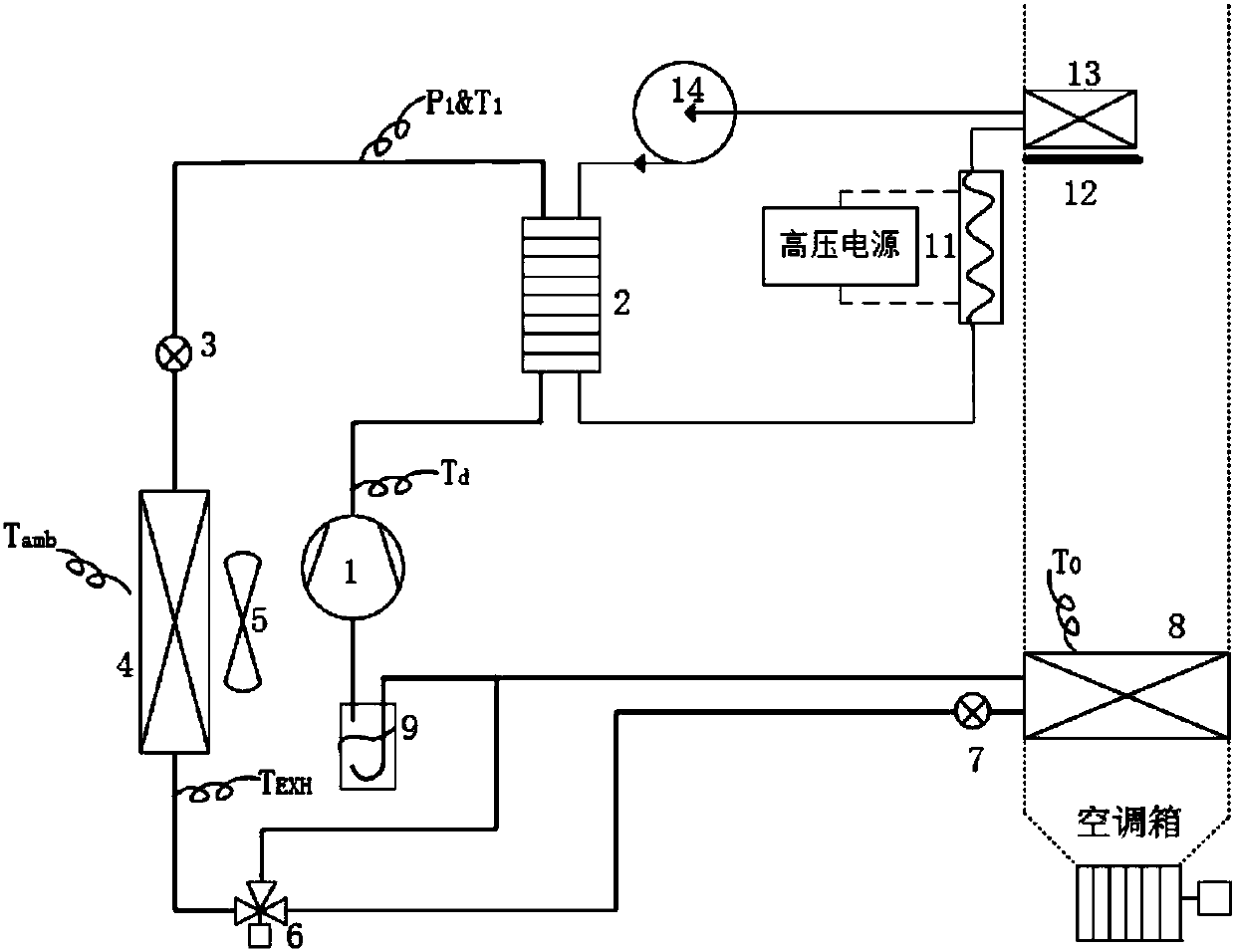

[0056] Such as figure 1 As shown, it is a schematic diagram of the vehicle air-conditioning heat pump integrated system of the present invention, which includes two subsystems: a refrigerant circulation system (heat pump system) and a secondary loop system.

[0057] The refrigerant circulation system includes a compressor 1, a first plate heat exchanger 2, a first electronic expansion valve 3, a heat exchanger 4, a fan 5, a three-way solenoid valve 6, a second electronic expansion valve 7, and an indoor evaporator 8 , and the liquid storage separator 9; wherein:

[0058] The compressor 1, the first plate heat exchanger 2, the first electronic expansion valve 3, the heat exchanger 4, the three-way solenoid valve 6, the second electronic expansion valve 7, the indoor evaporator 8, and the liquid storage separator 9 pass through the pipe The circuits are connected in turn to form a cycle; wherein, the ...

Embodiment 2

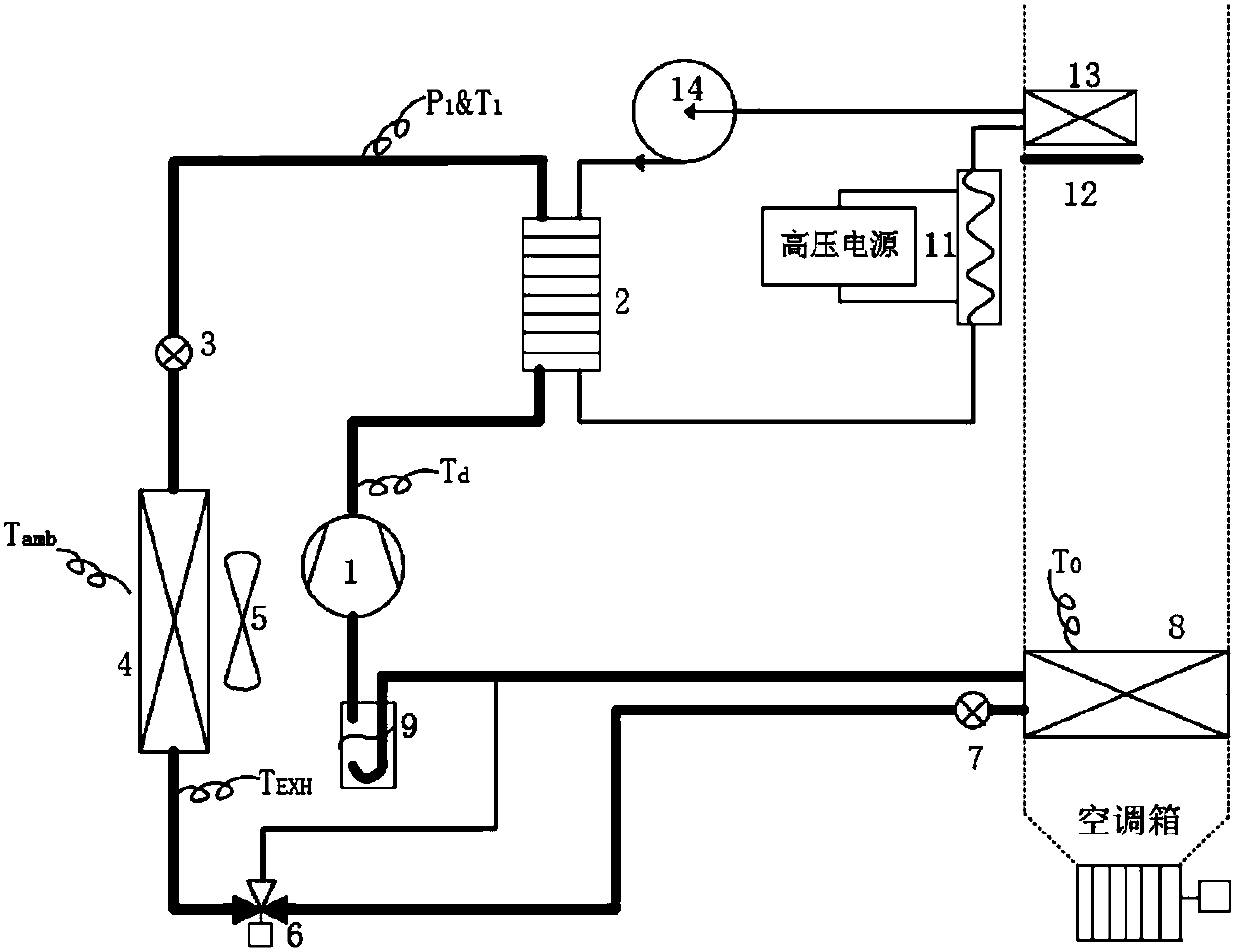

[0065] Embodiment 2, cooling mode

[0066] When the temperature inside the car is high and the temperature inside the car needs to be lowered, the system operates in cooling mode. Such as figure 2 As shown, in the refrigerant circulation system, the high-temperature and high-pressure gaseous refrigerant discharged from the compressor 1 passes through the first plate heat exchanger 2, enters the outdoor heat exchanger 4, releases heat into the atmosphere of the external environment, and becomes a liquid refrigerant, and then After passing through the three-way solenoid valve 6, the liquid refrigerant flows into the second electronic expansion valve 7 for throttling, becomes a low-pressure and low-temperature two-phase refrigerant, and then enters the indoor evaporator 8 to absorb the heat of the air blown by the blower in the air-conditioning box, and becomes a two-phase refrigerant. The phase / gaseous refrigerant enters the liquid storage separator 9, and in the liquid storag...

Embodiment 3

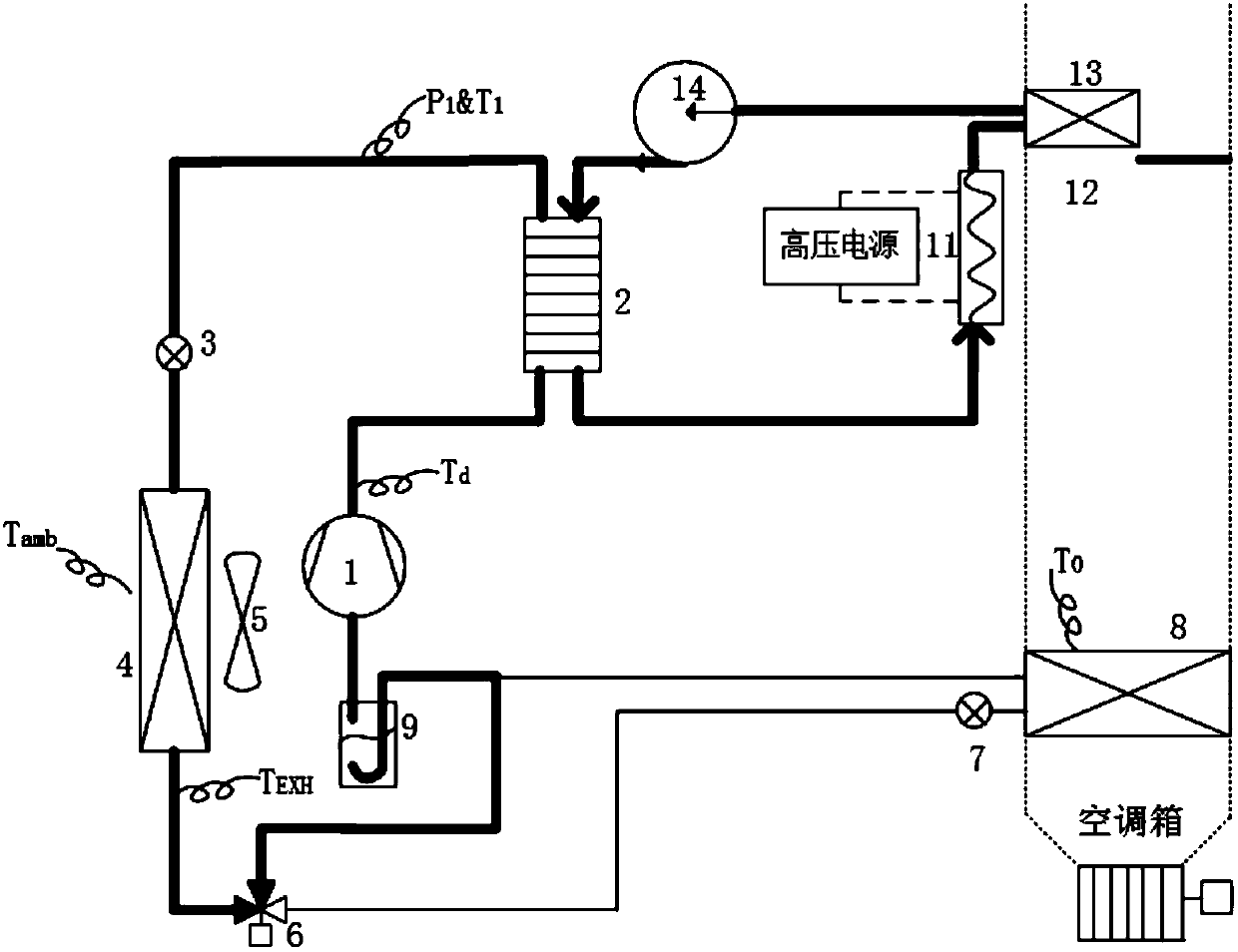

[0068] Embodiment 3, heat pump heating mode

[0069] When the temperature inside the car is low and the car needs to be heated, the system will turn on the heat pump heating mode, because in terms of improving energy utilization, the heating efficiency of the heat pump is greater than 1, while the heating efficiency of PTC water is less than 1, so it will not be used to turn on the PTC heating mode alone. Heat mode, supplying heating to the passenger compartment. Such as image 3 As shown, in the refrigerant circulation system, the high-temperature and high-pressure gaseous refrigerant discharged from the compressor 1 enters the first plate heat exchanger 2, releases heat into the circulating water of the secondary circuit, becomes a liquid refrigerant, and then enters the first electronic expansion valve 3 throttling, it becomes a two-phase refrigerant, and enters the outdoor heat exchanger 4, absorbs the heat of the atmosphere in the external environment, becomes a two-phas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com