Landfill leachate treatment method

A technology of landfill leachate and a treatment method, which is applied in the field of landfill leachate treatment, can solve the problems of increasing difficulty in leachate treatment, increasing the dosage of various chemicals, and increasing operating costs, so as to ensure that the effluent quality meets the standard and reduce the number of chemicals. The effect of dosage and operation cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

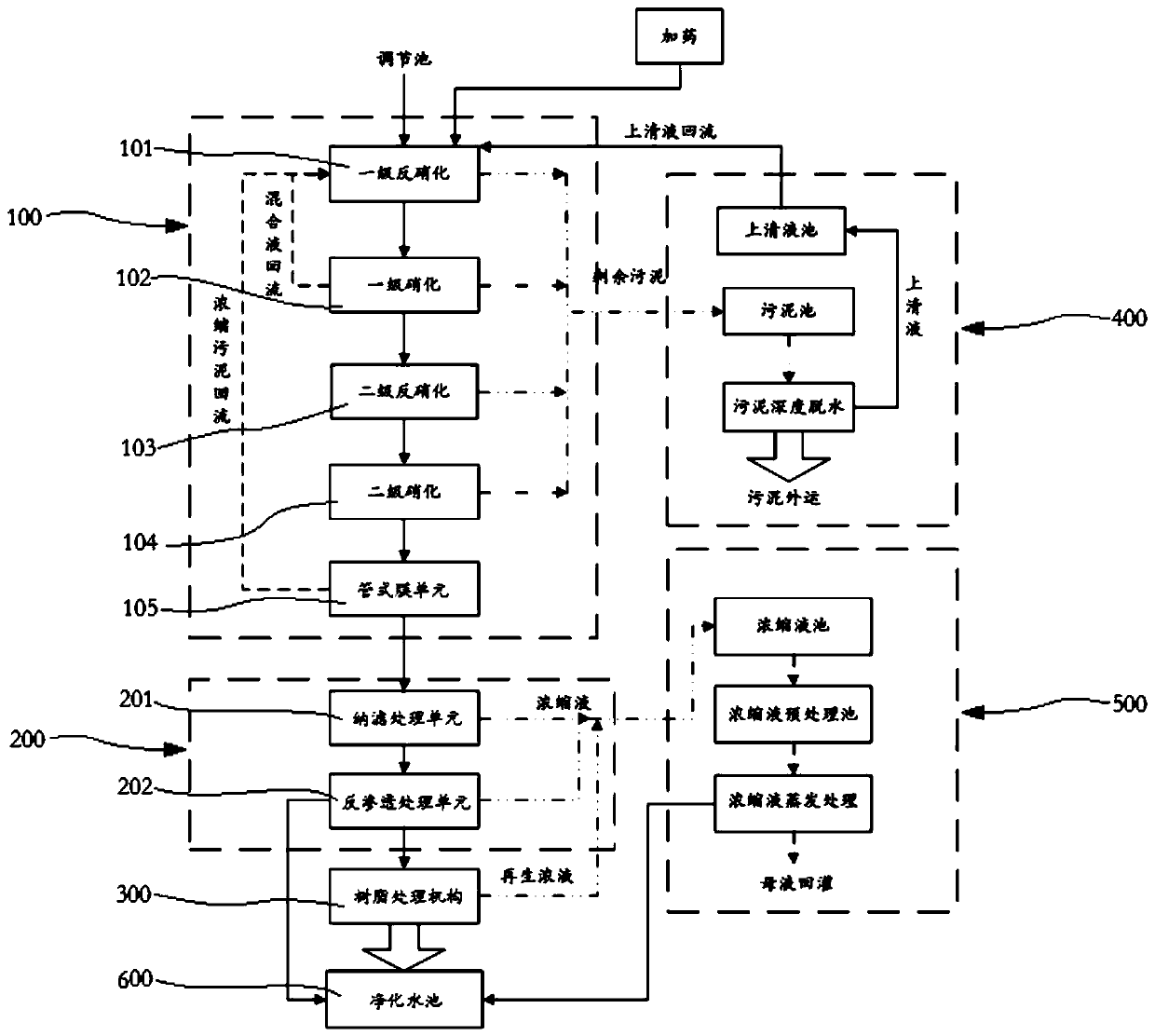

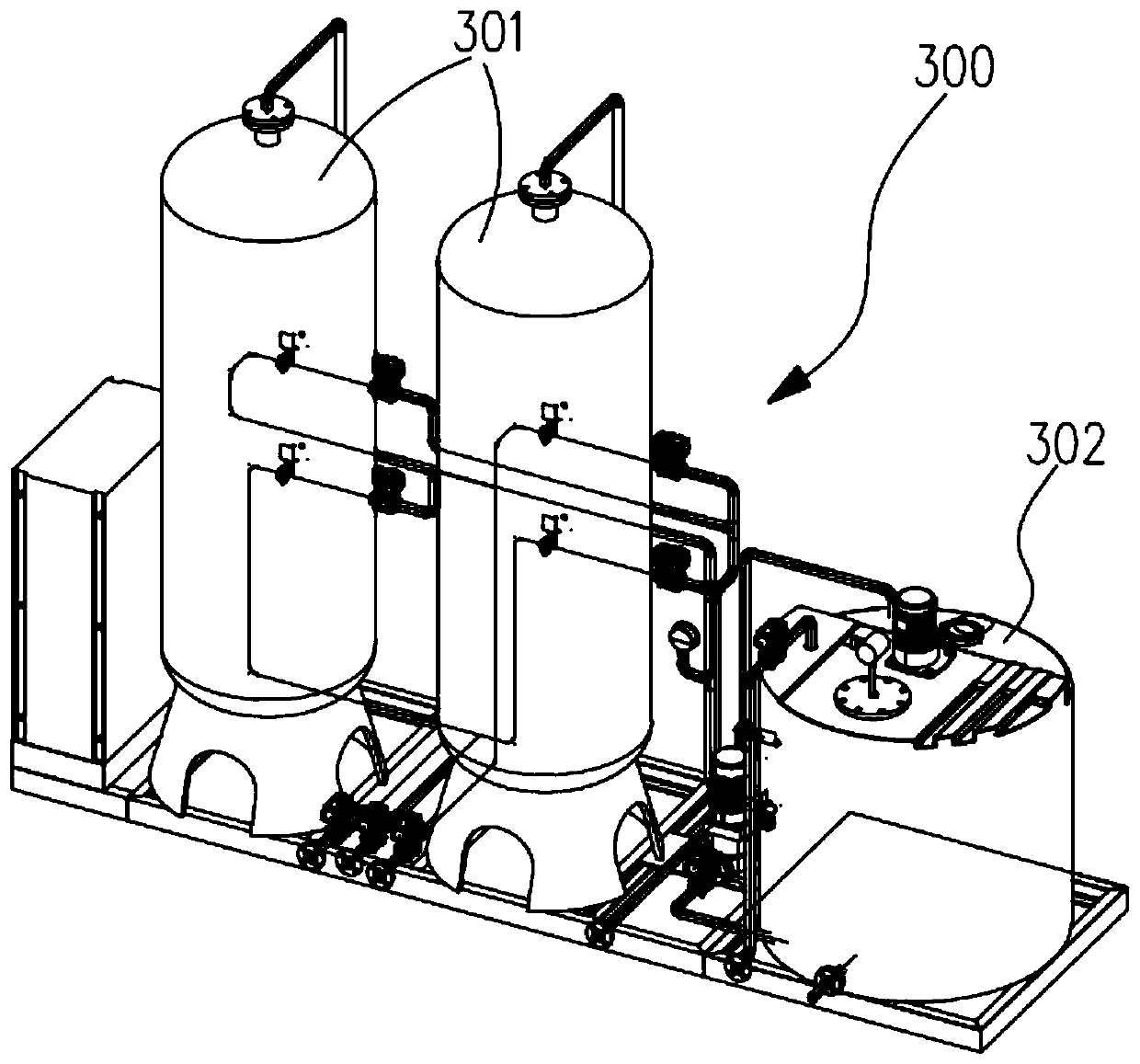

[0027] like figure 1 An embodiment of the present invention provides a landfill leachate treatment system, including a biochemical treatment mechanism 100, an advanced treatment mechanism 200, and a resin treatment mechanism 300. Along the leachate flow direction, the biochemical treatment mechanism 100, the advanced treatment mechanism 200 and the The resin processing mechanisms 300 are connected sequentially.

[0028] Existing biochemical treatment mechanisms 100 are applicable to this embodiment. As a preferred embodiment, such as figure 1 , the biochemical treatment mechanism 100 includes at least one stage of denitrification-nitrification units; when the denitrification-nitrification units have multiple stages, each of the denitrification-nitrification units is connected in series. The denitrification-nitrification unit is a conventional processing unit in the field, including a denitrification unit and a nitrification unit, and there is a mixed liquid return channel be...

Embodiment 2

[0066] like figure 1 , the embodiment of the present invention provides a landfill leachate treatment method, comprising the following steps:

[0067] S1, performing at least one denitrification-nitrification treatment on the leachate;

[0068] S2, the leachate after denitrification-nitration treatment is treated by tubular membrane filtration;

[0069] S3, the tubular membrane effluent is further treated by membrane filtration;

[0070] S4, using the resin adsorption method to perform denitrification treatment on the filtrate after the advanced membrane filtration treatment to obtain the standard discharge liquid.

[0071] Among them, the above-mentioned denitrification-nitration treatment steps, tubular membrane filtration treatment steps, membrane filtration advanced treatment steps and resin adsorption steps have corresponding content descriptions in the above-mentioned embodiment one, and can refer to the relevant content in the above-mentioned embodiment one , which w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com