Preparation method of composite material, composite material and super-capacitor

A technology of composite materials and nanocomposites, which is applied in the preparation of composite materials, composite materials and supercapacitors, and can solve the problems of complex preparation process and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

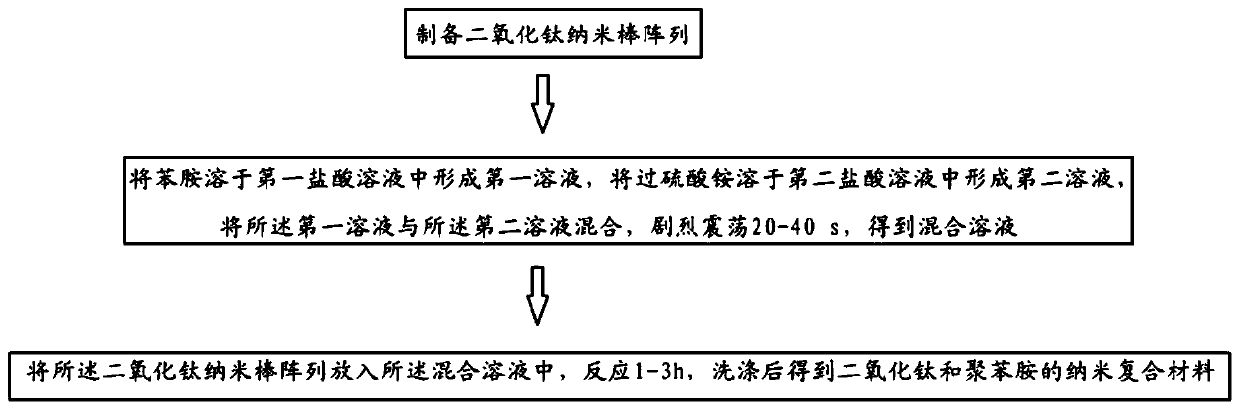

[0021] see figure 1 , a method for preparing a composite material provided in an embodiment of the present invention includes the following steps:

[0022] Step S1, preparing a titania nanorod array.

[0023] Step S2, dissolving aniline in the first hydrochloric acid solution to form a first solution, dissolving ammonium persulfate in a second hydrochloric acid solution to form a second solution, mixing the first solution and the second solution, and shaking vigorously for 20-40s to obtain mixture.

[0024] Step S3, putting the titanium dioxide nanorod array into the mixed solution, reacting for 1-3 hours, and obtaining a nanocomposite material of titanium dioxide and polyaniline after washing.

[0025] Specific embodiments of the application to prepare titanium dioxide nanorod arrays, the obtained titanium dioxide nanorod arrays can increase the electron transport rate, aniline is dissolved in the first hydrochloric acid solution to form the first solution, and ammonium per...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com