Preparation method of paclitaxel injection resistant to terminal sterilization

A technology for preparing injection and paclitaxel, which is applied in the field of preparing paclitaxel injection and the preparation of paclitaxel injection resistant to terminal sterilization, can solve the problems of inability to terminal sterilization and poor thermal stability of paclitaxel, and achieves prolonged storage time, The effect of prolonging the storage time and avoiding the degradation of substances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

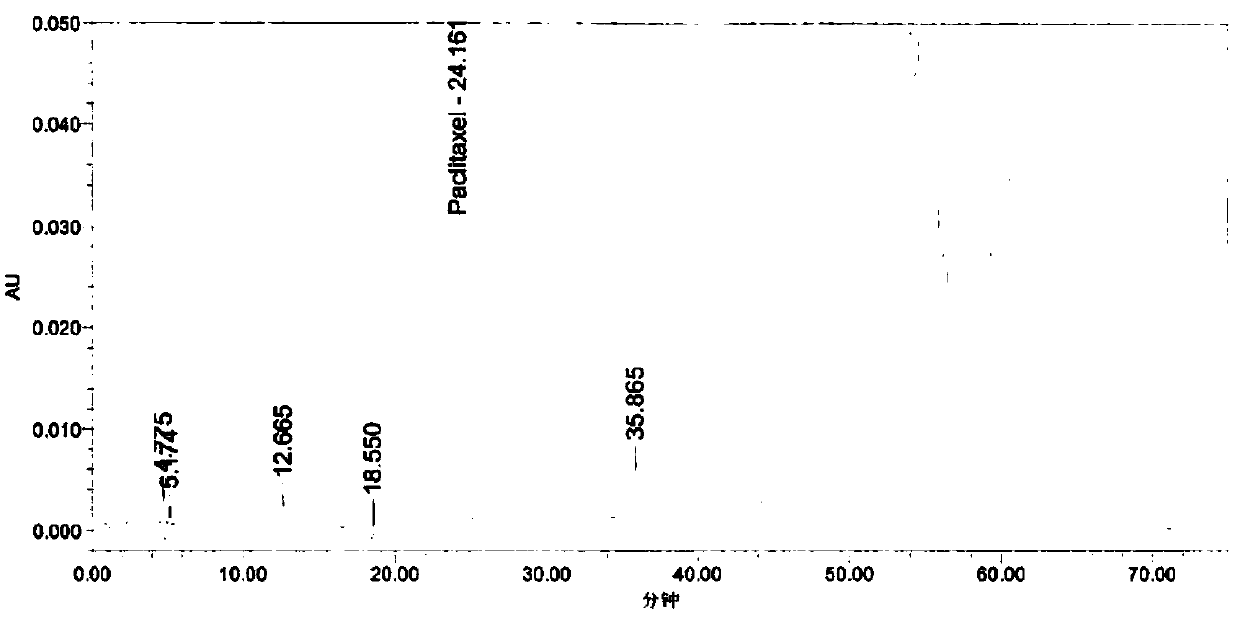

Embodiment 1

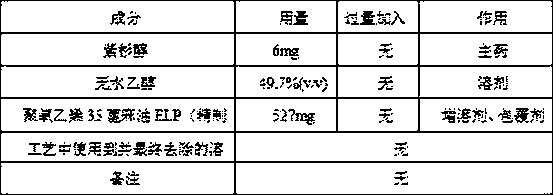

[0033] The preparation method of paclitaxel injection resistant to terminal sterilization of embodiment 1 comprises the following steps:

[0034] (1) Add the prescribed amount of paclitaxel to the prescribed amount of polyoxyethylene (35) castor oil, and stir and shear at a high speed for more than 120 minutes under the condition of a rotation speed ≥ 4000 rpm to obtain solution A; the details are as follows:

[0035] Wash the liquid preparation tank and pipeline with absolute ethanol for 3 times; take the prescribed amount of polyoxyethylene (35) castor oil and add it to the liquid preparation tank; Cut for 120 minutes, dissolve paclitaxel and wrap it into polyoxyethylene (35) castor oil to obtain solution A.

[0036] (2) Add the prescribed amount of absolute ethanol to solution A, and stir until the solution is evenly mixed to obtain solution B;

[0037] (3) Deoxygenate solution B; details are as follows:

[0038] Feed clean nitrogen into solution B until the dissolved oxy...

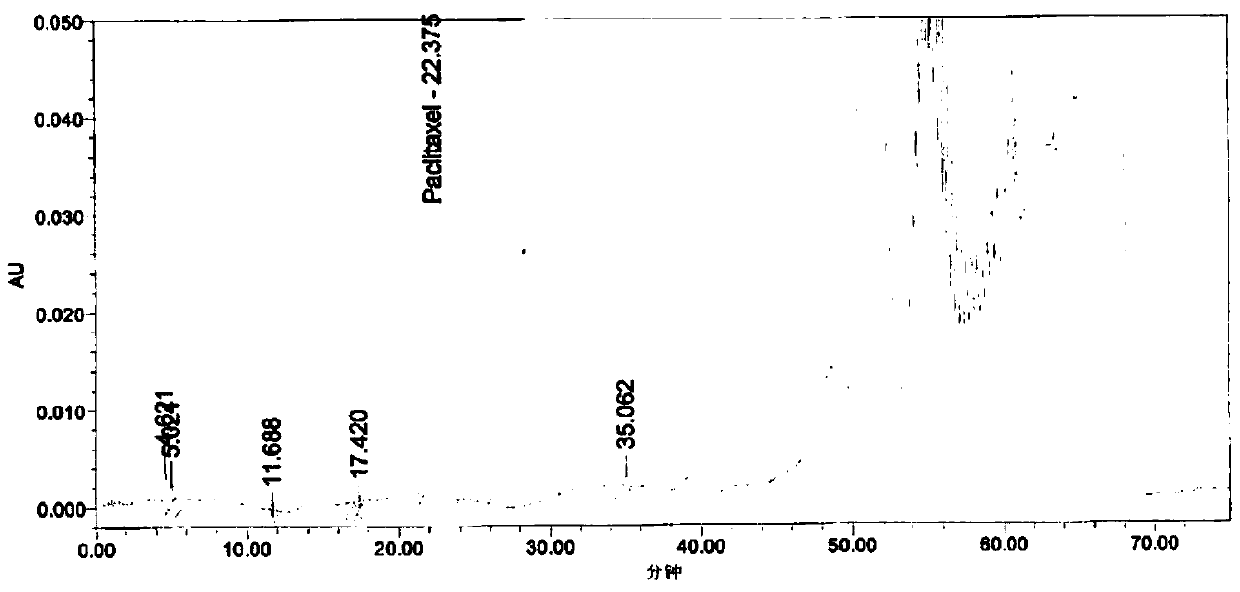

Embodiment 2

[0042] The preparation method of the paclitaxel injection resistant to terminal sterilization of embodiment 2 comprises the following steps:

[0043] (1) Add the prescribed amount of paclitaxel to the prescribed amount of polyoxyethylene (35) castor oil, and stir and shear at a high speed for more than 120 minutes under the condition of a rotation speed ≥ 4000 rpm to obtain solution A; the details are as follows:

[0044] Wash the liquid preparation tank and pipeline with absolute ethanol for 3 times; take the prescribed amount of polyoxyethylene (35) castor oil and add it to the liquid preparation tank; Cut for 120 minutes, dissolve paclitaxel and wrap it into polyoxyethylene (35) castor oil to obtain solution A.

[0045] (2) Add the prescribed amount of absolute ethanol to solution A, and stir until the solution is evenly mixed to obtain solution B;

[0046] (3) Deoxygenate solution B; details are as follows:

[0047]Pass clean nitrogen into solution B until the dissolved ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com