Conformal cutting layer and path planning method for curved surface 3D printing

A path planning and 3D printing technology, applied in the field of surface 3D printing, which can solve the problem of failure to consider the force distribution and path shape when the part is stressed, can not fully adapt to surface layering and path planning, ignore the impact of mechanical properties of parts, etc. problems, to save material and printing time, improve step effects, reduce gaps and voids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

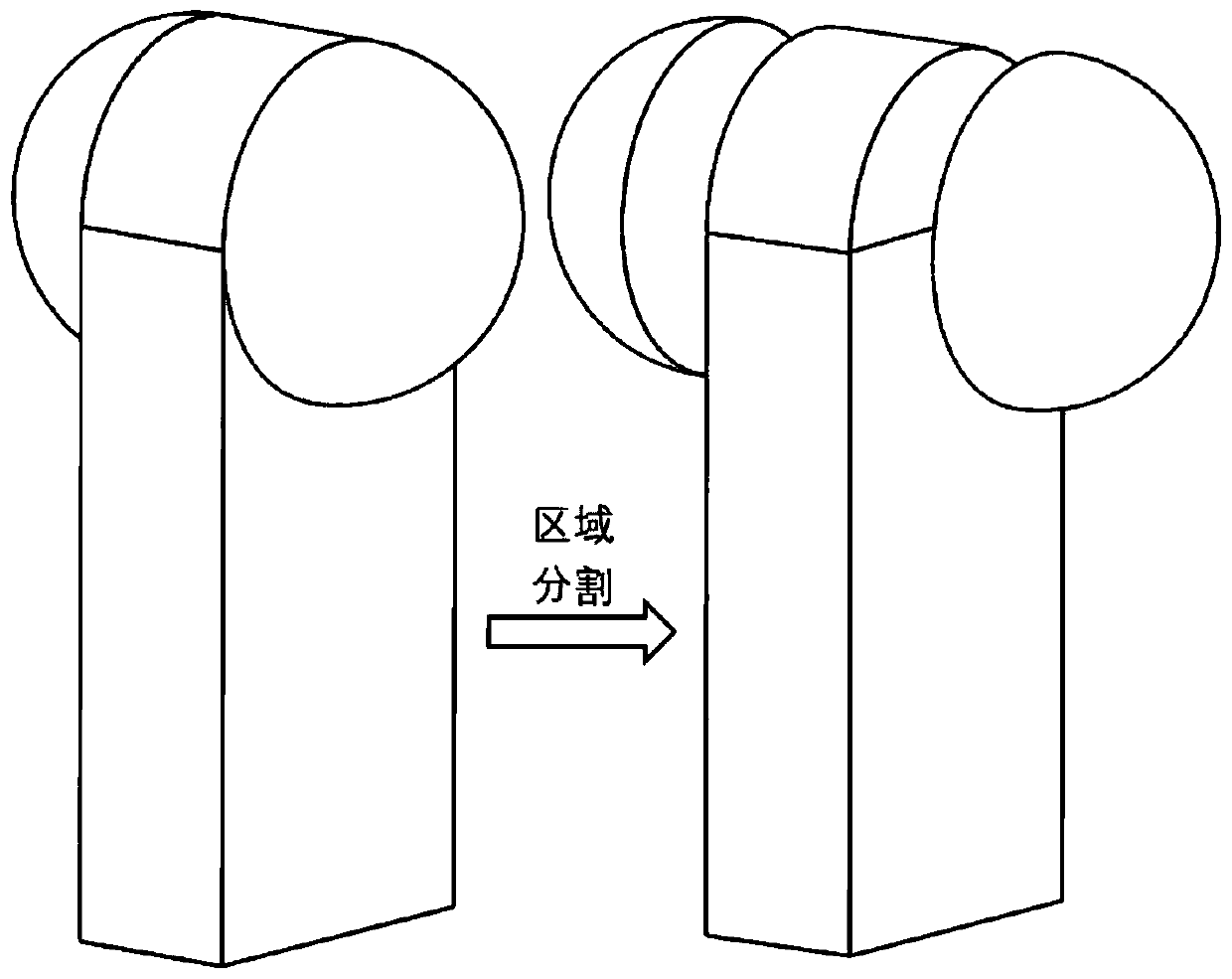

[0040] This embodiment performs model layering and spatial path planning for the FDM process. The model to be printed is as follows: figure 2 As shown, the file format is OBJ, and the multi-axis printer used is composed of two parts: the upper nozzle is fixed at the end of the ABB six-degree-of-freedom robotic arm, and the lower part, which is used to carry parts, is fixed on the two-axis turntable.

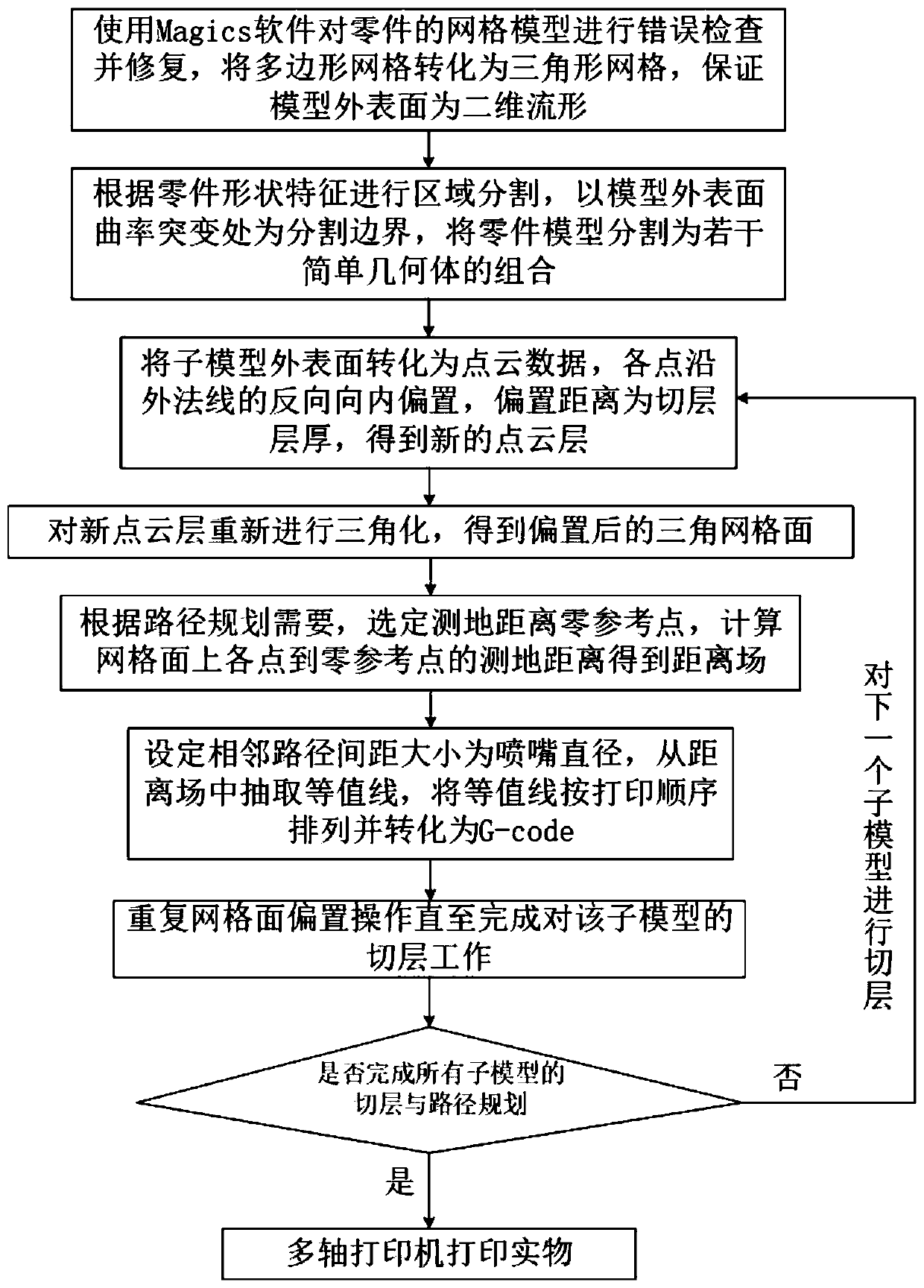

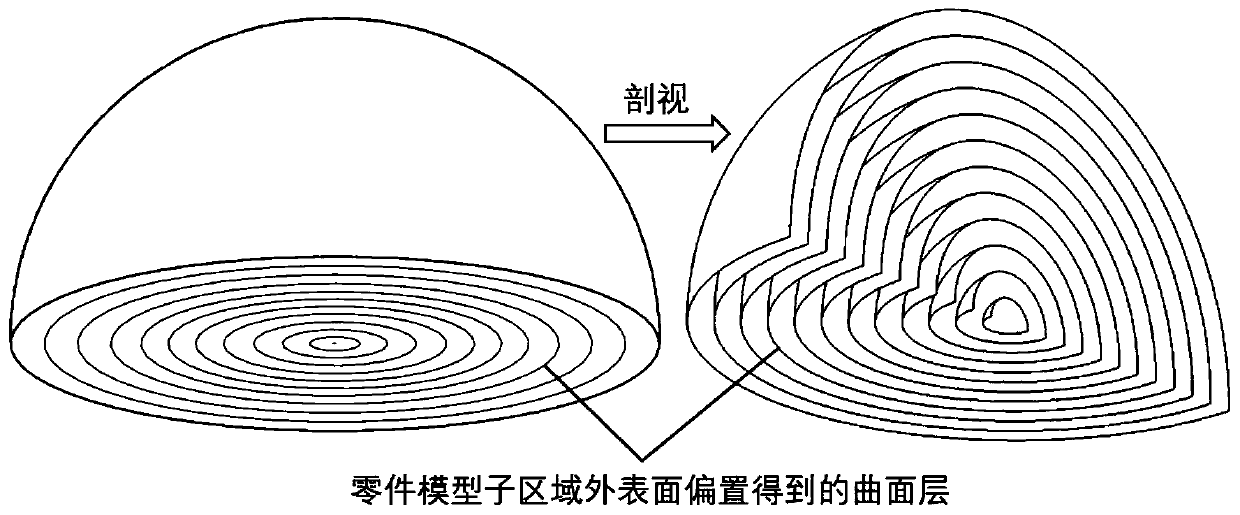

[0041] refer to figure 1 , a method for conformal layer slicing and path planning for curved surface 3D printing, comprising the following steps:

[0042] 1) Use Solidworks software to establish such as figure 2 (Left) Part model M as shown, then save the model as a file in OBJ format, check its outer surface S 0 Whether it is a two-dimensional manifold, if the meshes in the model are not all triangular units, first perform mesh triangulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com