Biaxially oriented polyester film with excellent dimensional stability at high temperature, and production method thereof

A biaxially oriented polyester, dimensional stability technology, applied in the field of polymer films, can solve the problems of decreased dimensional stability, limited application range, poor heat resistance and high temperature dimensional stability, etc. The effect of good toughness and excellent high temperature dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

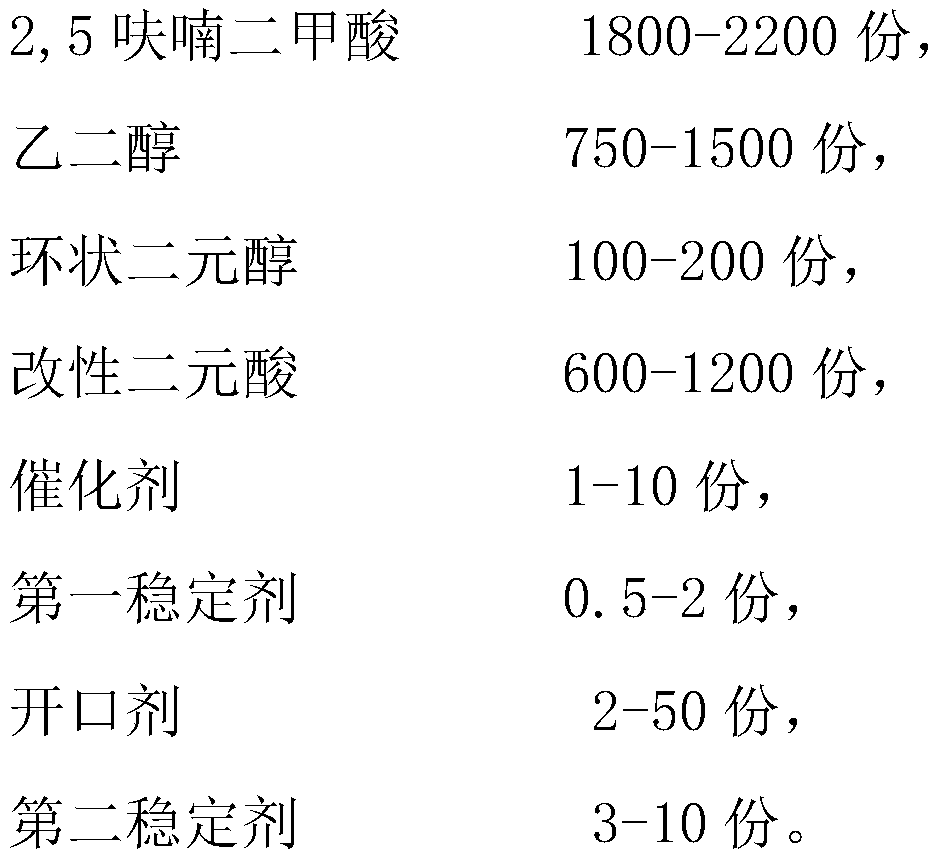

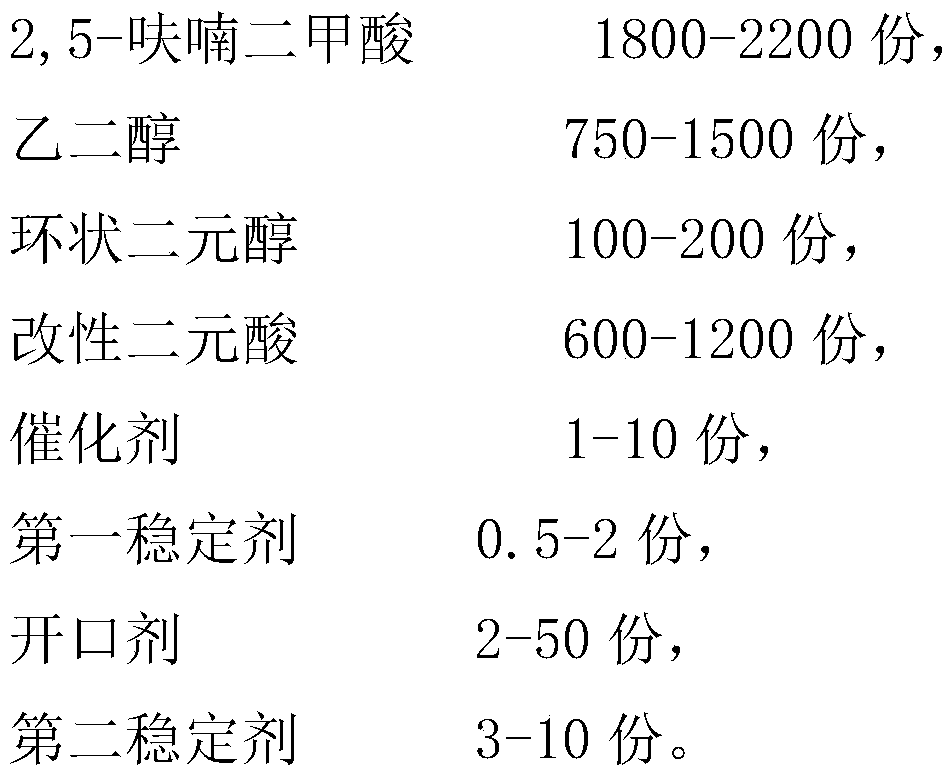

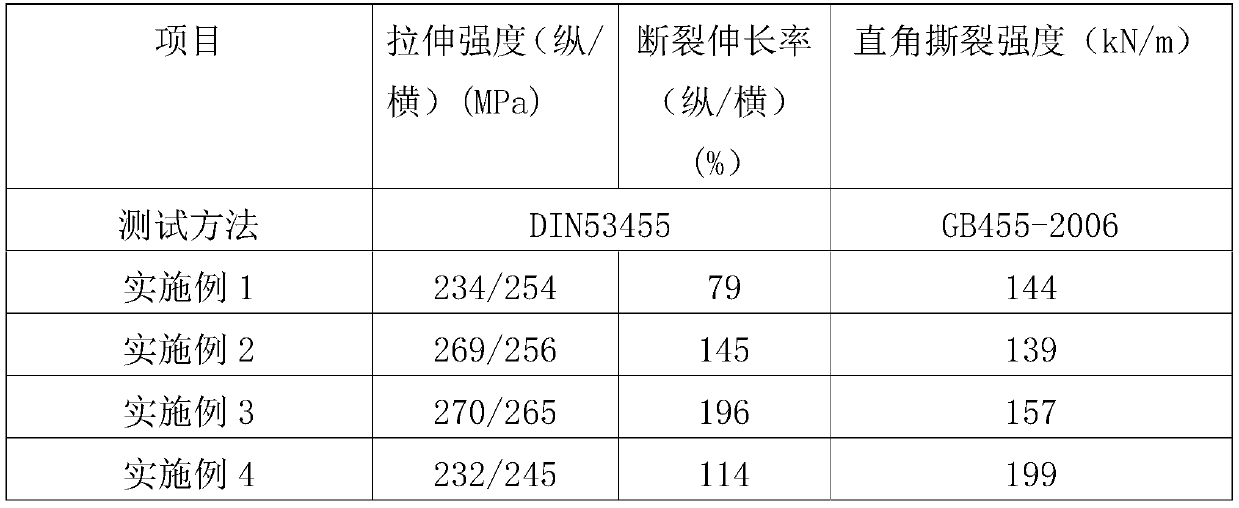

[0020] Weigh the following raw materials in parts by weight: 2000g of tere-2.5-furandicarboxylic acid, 870g of ethylene glycol, 100g of 1,4-cyclohexanedimethanol, 600g of terephthalic acid, 5g of ethylene glycol antimony catalyst, and 1.5 g of triphenyl phosphate g, 3g of silica blocking agent with a particle size of 5 μm, and 5g of EV234.

[0021] Mix the above weighed 2.5-furandicarboxylic acid, ethylene glycol, 1,4-cyclohexanedimethanol, terephthalic acid, ethylene glycol antimony catalyst, silicon dioxide opening agent, EV234, and add to 5L reactor, stirring for half an hour. Then slowly vacuum the reactor to below 100Pa, then slowly fill the reactor with nitrogen to 250KPa, and then slowly release the nitrogen. After repeating this twice, raise the temperature and pressure of the reactor to carry out the esterification reaction, and maintain the reaction during the esterification process. The temperature in the kettle is 230° C., and the pressure inside the reactor is ke...

Embodiment 2

[0025] Weigh the following raw materials in parts by weight: 1,800 g of 2,5-furandicarboxylic acid, 750 g of ethylene glycol, 200 g of isosorbide, 1,200 g of 1,4 cyclohexanedicarboxylic acid, 1 g of ethylene glycol antimony catalyst, and 0.5 g of triphenyl phosphate , 2g of barium sulfate opening agent with a particle size of 5μm, 3g of ST13006.

[0026] Mix the above weighed 2,5-furandicarboxylic acid, ethylene glycol, isosorbide, 1,4-cyclohexanedicarboxylic acid, ethylene glycol antimony catalyst, barium sulfate opening agent and ST13006, add to 5L reaction In the kettle, stir for half an hour. Then slowly vacuum the reactor to below 100Pa, then slowly fill the reactor with nitrogen to 250KPa, and then slowly release the nitrogen. After repeating this twice, raise the temperature and pressure of the reactor to carry out the esterification reaction, and maintain the reaction during the esterification process. The temperature in the kettle is 240° C., and the internal pressur...

Embodiment 3

[0030] Weigh the following raw materials in parts by weight: 2100g of 2,5 furandicarboxylic acid, 1200g of ethylene glycol, 150g of 2,2,4,4-tetramethyl-1,3-cyclobutanediol, 900g of isophthalic acid, 7g of antimony glycol catalyst, 1g of triphenyl phosphate, 10g of silicon dioxide blocking agent with a particle size of 5μm, and 7g of EV234.

[0031] The above weighed 2,5 furandicarboxylic acid, ethylene glycol, 2,2,4,4-tetramethyl-1,3-cyclobutanediol, isophthalic acid, ethylene glycol antimony catalyst, di After mixing the silicon oxide anti-blocking agent and EV23 evenly, add it to the 5L reaction kettle and stir for half an hour. Then slowly evacuate the reactor to below 100Pa, then slowly pump nitrogen to 250KPa, and then slowly release the nitrogen. After repeating this twice, the reactor is heated and pressurized to carry out the esterification reaction, and the reactor is maintained during the esterification process. The internal temperature is 230°C, and the internal pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com