White primer composition and preparation method thereof

A composition and primer technology, applied in primers, coatings, polyurea/polyurethane coatings, etc., can solve the problems of inconspicuous opening effect, uneven paint film surface, and insufficient texture layering, etc., to achieve color development Ideal, simple preparation process, obvious effect of opening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Another aspect of the present invention also provides a preparation method of the white primer composition, comprising the steps of: 1) adding the polyurethane resin at a stirring speed of 400-600r / min.

[0034] In step 1), the water-based polyurethane resin is added into a container, such as a reaction kettle, and the stirring is started. The stirring is, for example, 400r / min, 500r / min, 600r / min.

[0035] The preparation method of the white primer composition of the present invention also includes the step: 2) adding the titanium white slurry, the wetting agent, the penetrating agent, the film-forming aid, the thickener and the Add water and continue to stir to prepare the white primer composition.

[0036] In step 2), the titanium dioxide slurry is prepared, for example, in the manner described above:

[0037]a) Add the water, the pH regulator, the dispersant, the defoamer, and the titanium dioxide to a container, such as a reactor;

[0038] b) stirring and disper...

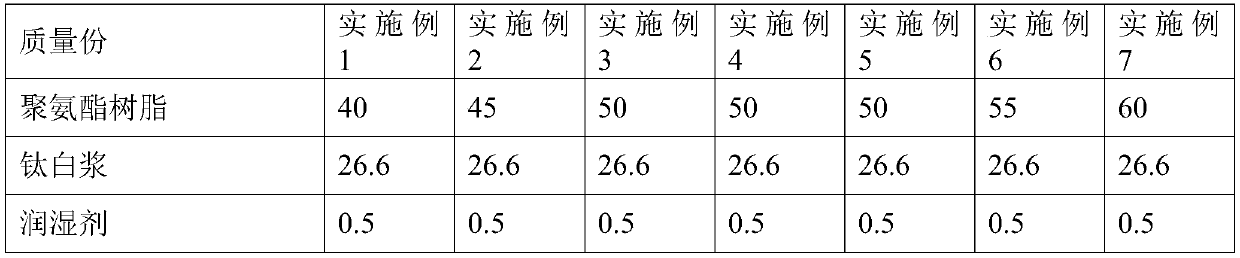

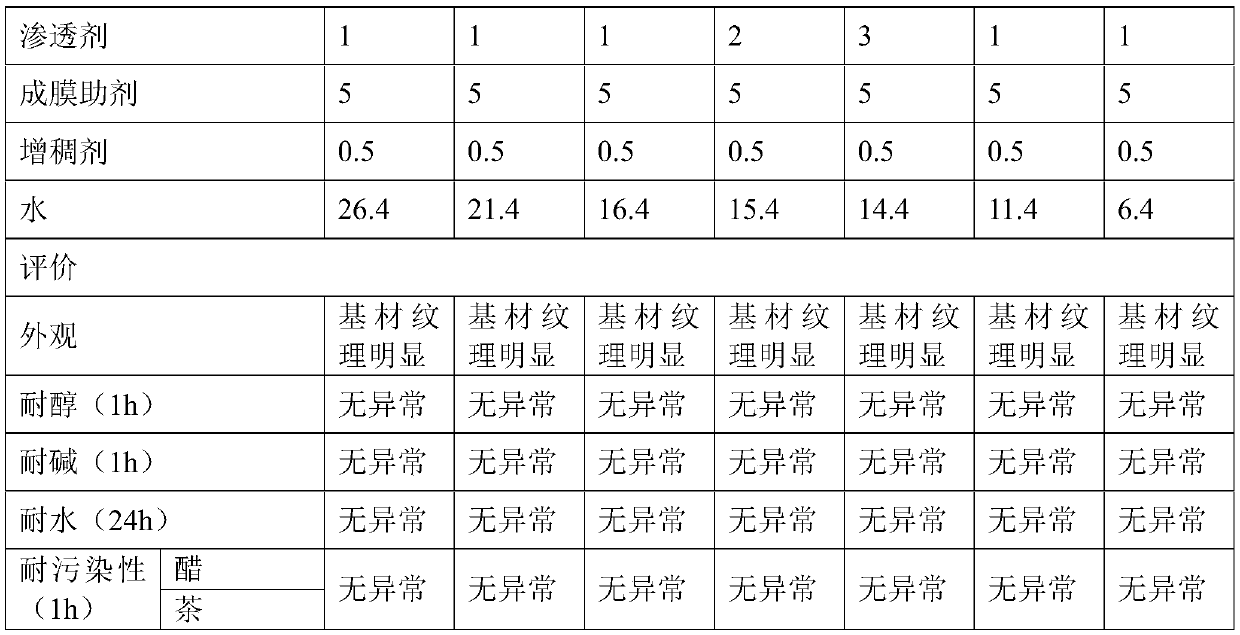

Embodiment 1

[0044] 1) Turn on the stirring speed of 400r / min, add 5g of water, 0.1g of AMP-95, 1g of BYK-190, 0.5g of Digo 902W, and 20g of titanium dioxide in the container, and increase the speed to 1200r / min for high-speed dispersion for 18min. A titanium white slurry was obtained, and its fineness was 15 μm after being tested by the scraper fineness meter.

[0045] 2) Weigh 40g of polyurethane resin and add it to the reaction kettle, turn on the stirring speed of 400r / min, and stir;

[0046] 3) In the reaction kettle, add 26.6g titanium white paste titanium white paste, 0.5g Digo 4100, 1g Siluoke 8141, 5g the DPM film-forming aid, 0.5g the Dow 2020 thickener and 26.4g of remaining water, and continued to stir for 30 minutes to prepare white primer composition 1, and the specific proportions are shown in Table 1.

Embodiment 2

[0048] 1) Turn on the stirring speed of 500r / min, add 5g of water, 0.1g of AMP-95, 1g of BYK-192, 0.5g of Digo 902W, and 20g of titanium dioxide in the container, and increase the speed to 1200r / min for high-speed dispersion for 15 minutes. A titanium white slurry was obtained, and its fineness was 15 μm after being tested by the scraper fineness meter.

[0049] 2) Weigh 45g of polyurethane resin and add it to the reaction kettle, and start stirring at a stirring speed of 400r / min;

[0050] 3) In the reaction kettle, add 26.6g titanium white paste titanium white paste, 0.5g Digo 4100, 1g Siluoke 8141, 5g the DPM film-forming aid, 0.5g the Dow 2020 thickener and 21.4g of remaining water, and continued to stir for 30 minutes to prepare white primer composition 2, and the specific proportions are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com