Apparatus and method for uniformly mixing ice powder and sand or soil

A technology of uniform mixing and ice powder, applied in the preparation of test samples, etc., can solve the problem of difficulty in obtaining samples, and achieve the effect of simple and efficient method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

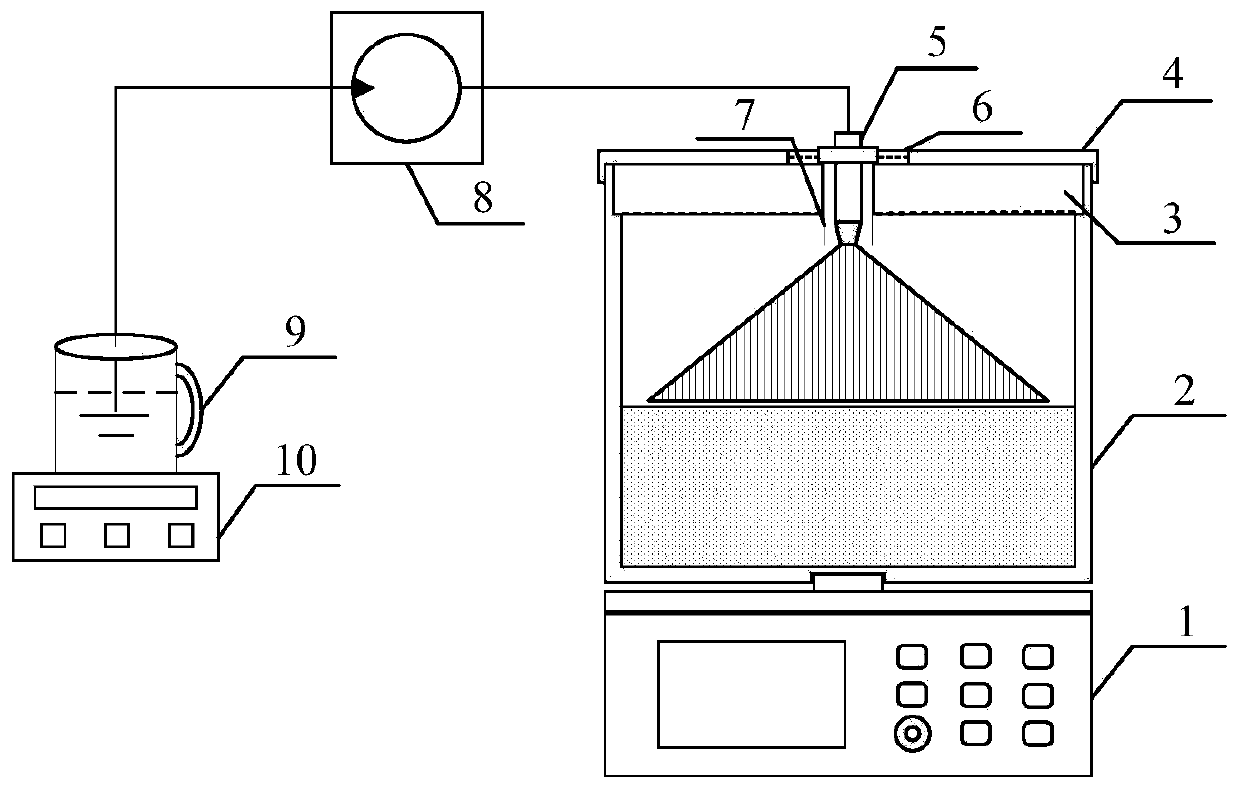

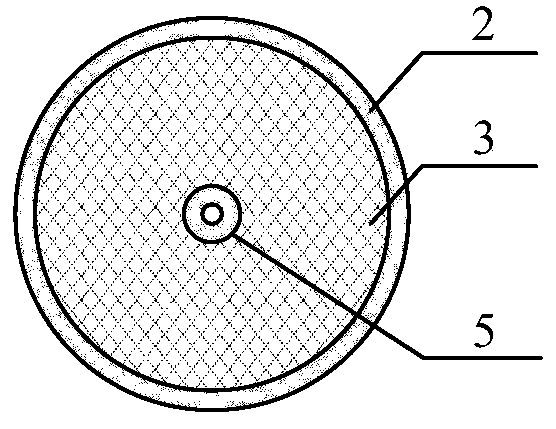

[0028] Embodiment one, refer to figure 1 , the present embodiment proposes a device for evenly mixing ice powder and sand, including an adjustable-speed rotator 1, a stainless steel container 2, a filter screen 3, an atomizing nozzle 5, a ventilation hole 6, a protective cover 7, a constant flow Pump 8, water cup 9 and mass scale 10.

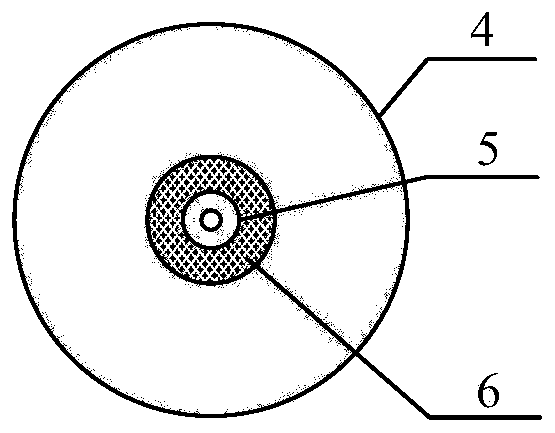

[0029] The stainless steel container 2 includes a stainless steel container main body and an upper cover 4, the bottom of the stainless steel container main body is connected with the adjustable speed rotator 1 through a slot, and a filter screen 3 is placed in the upper groove; the stainless steel container 2 An atomizing nozzle 5 is installed in the middle of the upper cover 4 .

[0030] A protective cover 7 is provided at the contact between the outside of the atomizing nozzle 5 and the filter screen 3; the atomizing nozzle 5 is connected to the outlet of the constant flow pump 8 through a pipeline, and the inlet of the constant flow pump 8 ...

Embodiment 2

[0035] Embodiment 2, this embodiment proposes a method for evenly mixing ice powder and sand, combining figure 1 The specific steps are described as follows:

[0036] (1) Place the stainless steel container 2 on the adjustable speed rotator 1, open the upper cover 4 of the stainless steel container 2, remove the filter screen 3, pour an appropriate amount of liquid nitrogen into the stainless steel container 2, and install the filter screen in sequence 3. Atomizing nozzle 5 and its protective cover 7;

[0037] (2) After the filter screen 3 is pre-cooled with liquid nitrogen, pour an appropriate amount of dry sand (or soil) into the filter screen 3, and spread it evenly, and then install the upper cover 4 of the stainless steel container 2;

[0038] (3) Pour secondary deionized distilled water into the water cup 9, and weigh the quality with a mass balance 10;

[0039] (4) Start the adjustable speed rotator 1 first, and the filter screen 3 moves and rotates under the drive of...

Embodiment 3

[0043] Embodiment three, this embodiment proposes a method for evenly mixing ice powder and sand, the difference from embodiment two lies in steps (3), (4) and (5), also refer to figure 1 ,Described as follows:

[0044] In step (1), liquid nitrogen is not poured into the stainless steel container 2; the steps (4) and (5) are carried out simultaneously, that is, the speed-adjustable rotator 1 and the constant-flow pump 8 are opened simultaneously to realize sand screening (or soil) and atomized water droplets in the simultaneous process, the atomized water droplets and sand (or soil) are evenly mixed, which can be used to prepare samples containing uniformly dispersed low-saturation gas hydrate in sediments.

[0045] In the method for uniform mixing of ice powder and sand, by adjusting the speed and time of the constant flow pump 8 and the speed-adjustable rotator 1, the mixture of atomized water droplets and dried sand (or soil) can be obtained. Proportion.

[0046] Other step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com