Method for improving flashover voltage of ceramic insulator

A ceramic insulator and flashover voltage technology, which is applied in the direction of insulators, circuits, electrical components, etc., can solve the problems that the coating cannot be used in complex structures, the reliability is not high, and the improvement of vacuum insulation flashover characteristics is not large. Improve vacuum surface flashover characteristics, less influencing factors, and improve the effect of surface breakdown voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

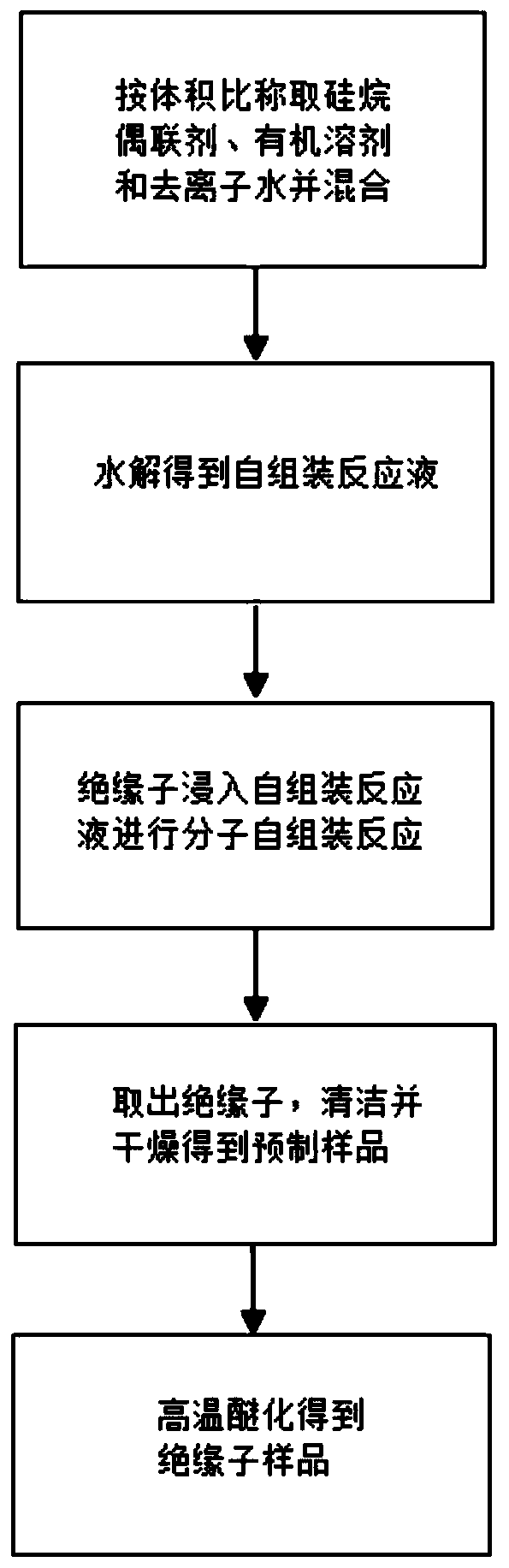

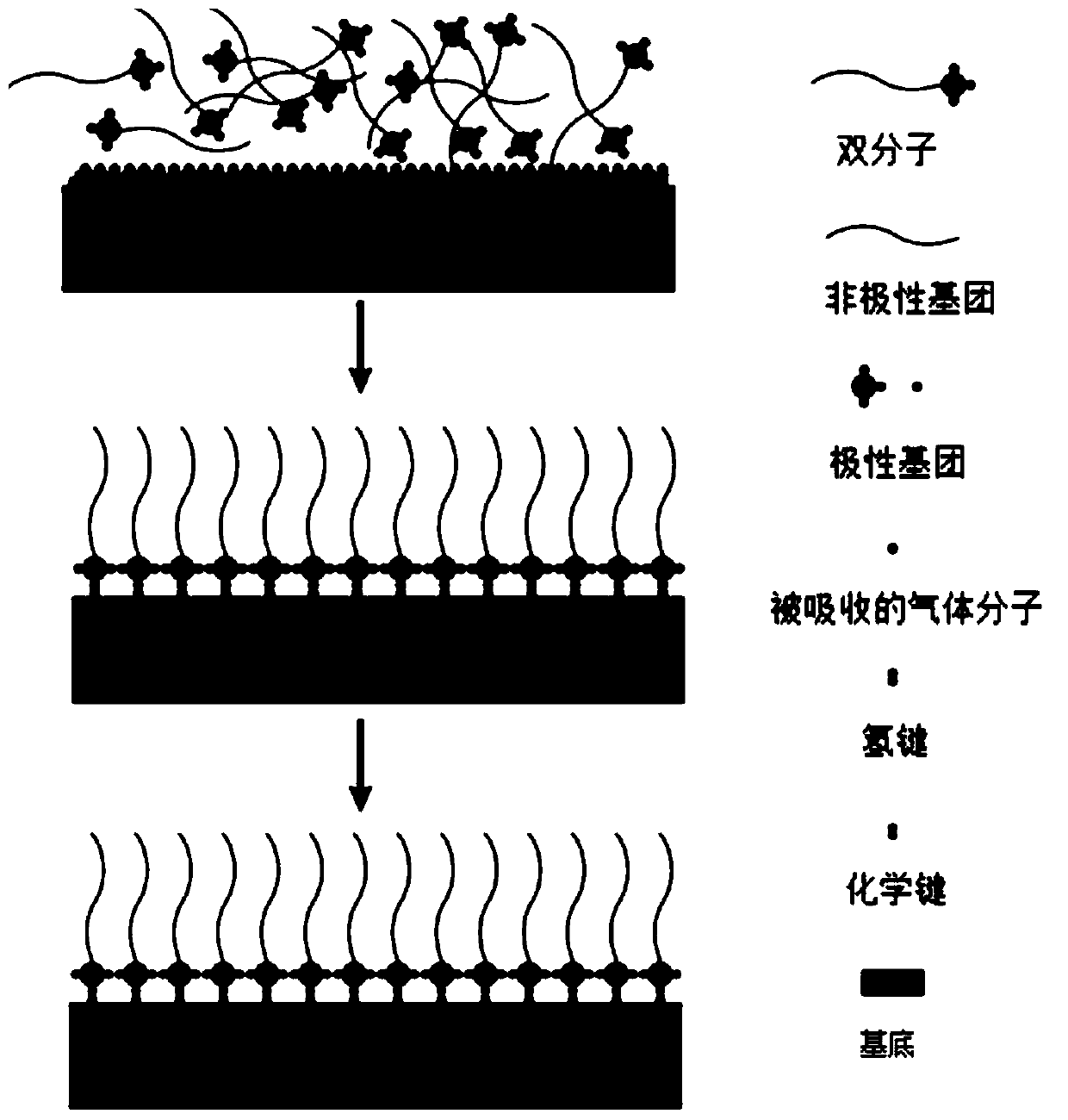

[0038] (1) Measure octadecyltrichlorosilane, deionized water and toluene according to the volume ratio of 1:1:30, and dissolve octadecyltrichlorosilane and deionized water in toluene to prepare octadecyltrichlorosilane The toluene solution of silane was stirred and hydrolyzed for 1 h at room temperature to obtain a self-assembly reaction solution;

[0039](2) Immerse a cylindrical aluminum oxide ceramic insulator with a diameter of 30 mm and a thickness of 10 mm in the above-mentioned self-assembly reaction solution and let it stand for 24 hours of molecular self-assembly reaction;

[0040] (3) Take out the insulator, use toluene, ethanol and water to clean it ultrasonically successively, remove the residue on the surface, and dry it under vacuum in an oven at 60°C for 6 hours;

[0041] (4) Raise the temperature of the oven to 120°C, keep it for 2 hours for high-temperature etherification, take it out after cooling, and finally obtain a ceramic insulator sample with a self-ass...

Embodiment 2

[0045] (1) Mix the silane coupling agent KH-570, deionized water and absolute ethanol at a volume ratio of 1:1:450, and perform stirring and hydrolysis at 40°C for 2 hours to obtain a self-assembly reaction solution;

[0046] (2) Immerse a cylindrical zirconia ceramic insulator with a diameter of 30mm and a thickness of 10mm in the self-assembly reaction solution, and carry out a molecular self-assembly reaction at 60°C for 6h;

[0047] (3) Ultrasonic cleaning with ethanol and deionized water successively to remove residues on the surface, and then vacuum drying in an oven at 60°C for 6 hours;

[0048] (4) Raise the temperature of the oven to 110°C for 2 hours for high-temperature etherification, then take it out after cooling, and finally obtain a ceramic insulator sample with a self-assembled film on the surface, which is designated as insulator sample 2.

Embodiment 3

[0050] (1) Measure the silane coupling agent KH-550, deionized water and acetone according to the volume ratio of 1:1:20, and dissolve the silane coupling agent KH-550 and deionized water in acetone to prepare the silane coupling agent KH- 550 of acetone solution, stirred and hydrolyzed for 10 h at room temperature to obtain a self-assembly reaction solution;

[0051] (2) Immerse a cylindrical silicate ceramic insulator with a diameter of 30 mm and a thickness of 10 mm in the above self-assembly reaction solution and let it stand for 12 hours of molecular self-assembly reaction;

[0052] (3) Take out the insulator, ultrasonically clean it with toluene, ethanol and water to remove the residue on the surface, and dry it in a vacuum oven at 60°C for 6 hours;

[0053] (4) Raise the temperature of the oven to 100° C., keep it for 2 hours for high-temperature etherification, take it out after cooling, and finally obtain a ceramic insulator sample with a self-assembled film on the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com