Infrared absorption film and preparation method thereof

An infrared absorption and film technology, applied in the field of infrared absorption film and its preparation, can solve the problems of poor compatibility of micromachining process, expensive preparation equipment, etc., and achieve the effects of enhancing infrared absorption rate, increasing roughness, and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

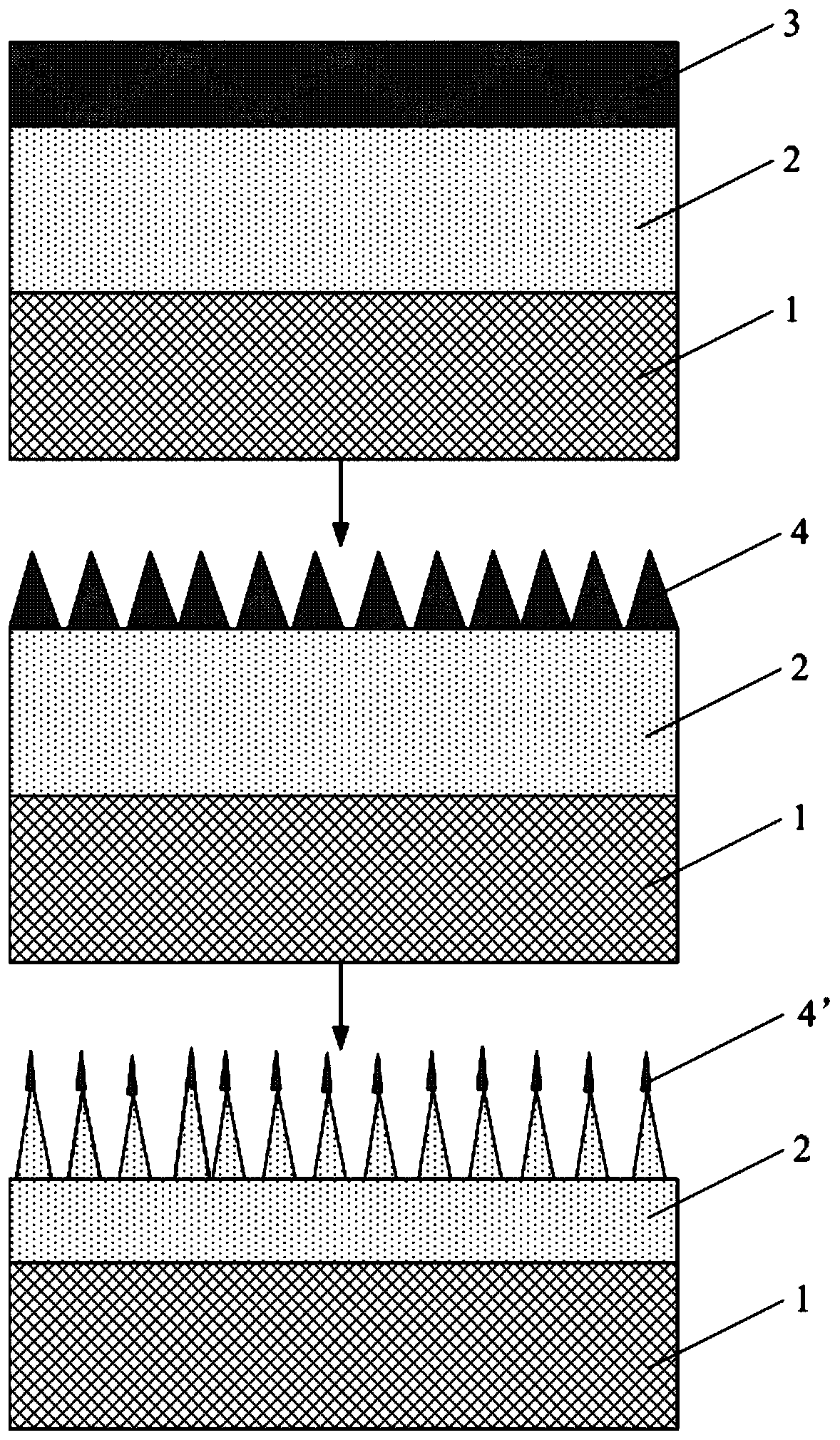

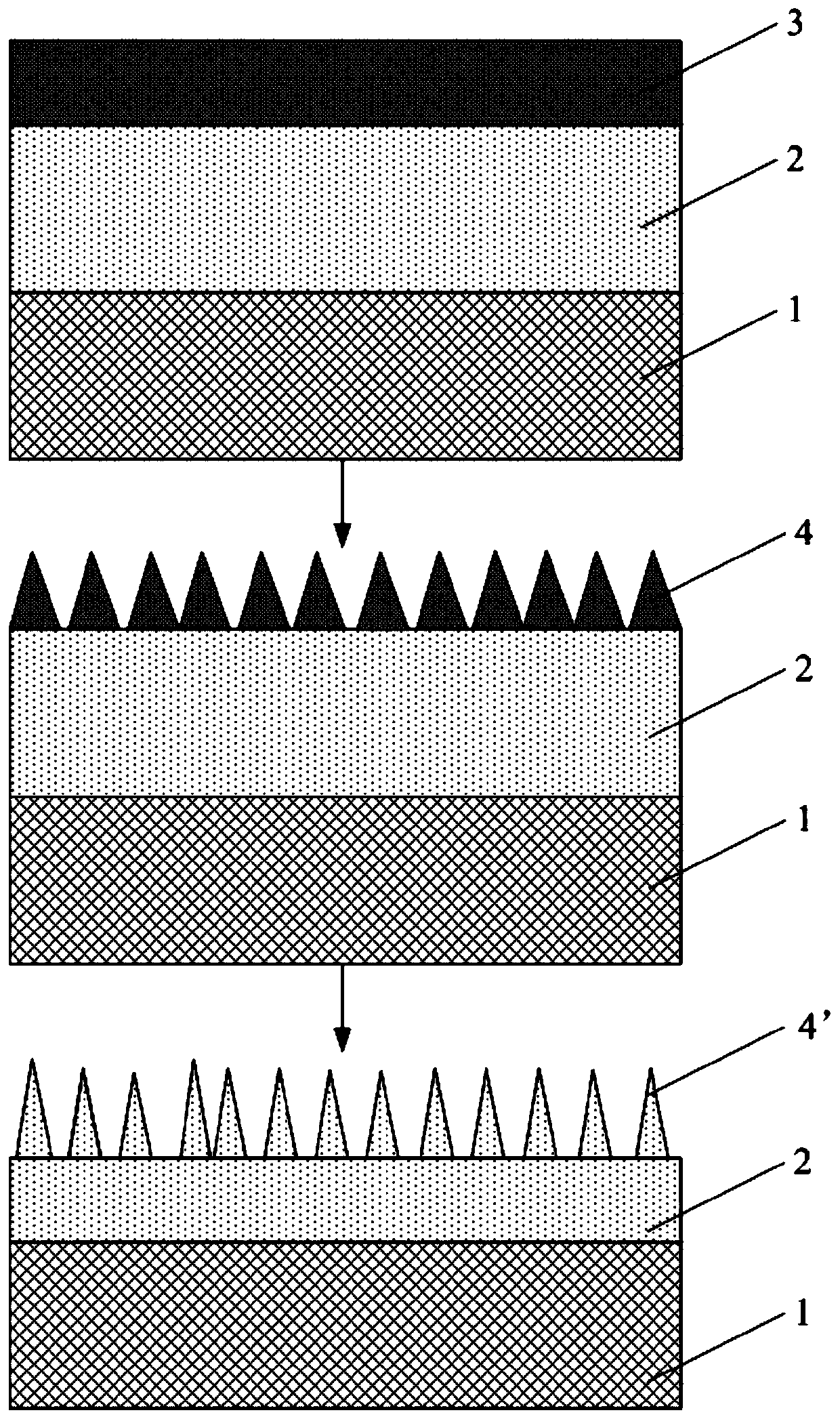

[0044] The application provides a method for preparing an infrared absorbing film, see Figure 1 to Figure 2 , including the following steps:

[0045] Form the sensitive layer 1 (for example, VO X layer or α-Si layer);

[0046] On the sensitive layer 1, an absorbing passivation layer 2 (for example, Si 3 N 4 layer) and graphic transfer layer 3;

[0047] Forming a nanostructure 4 on the side of the pattern transfer layer 3 away from the absorption passivation layer 2 by using the first plasma etching;

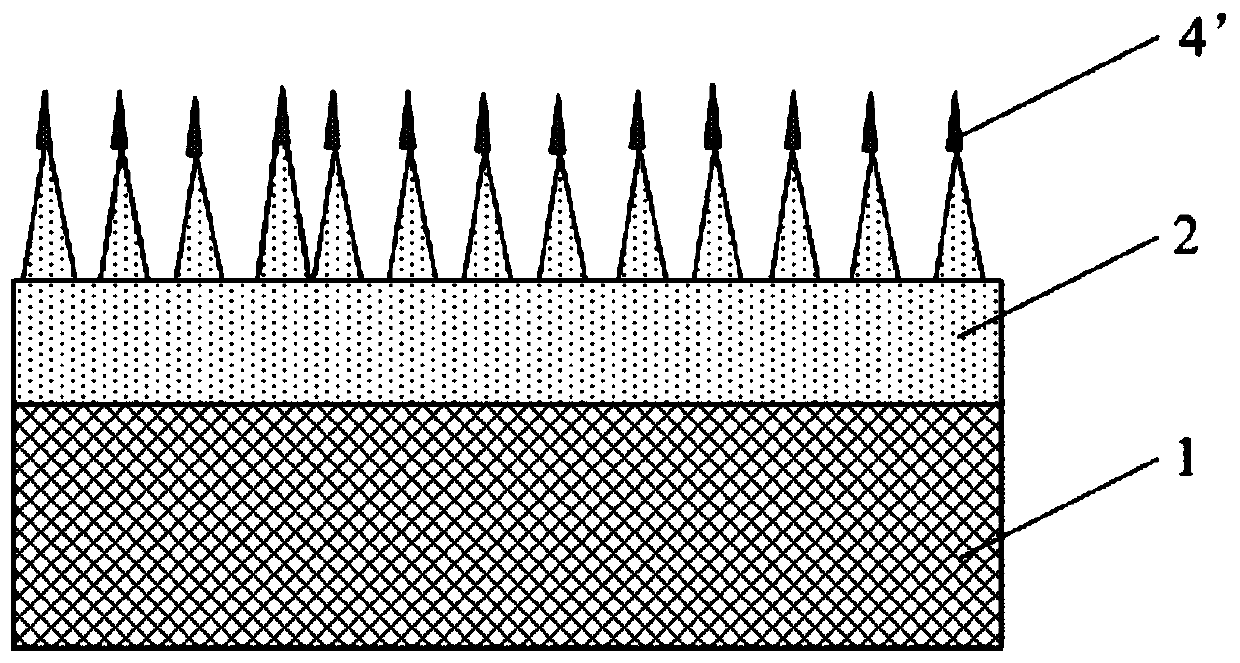

[0048] The nanostructure 4 of the pattern transfer layer 3 is transferred to the absorption passivation layer 2 by the second plasma etching, and the nanostructure 4' is formed on the side of the absorption passivation layer 2 away from the sensitive layer 1 to obtain an infrared absorption film.

[0049] It should be noted that the application of the preparation method of the infrared absorbing thin film of the present application is not limited to infrared absorption, and...

Embodiment 1

[0067] The preparation method of the infrared absorbing film of the present embodiment comprises the following steps:

[0068] form a sensitive layer;

[0069] An absorption passivation layer is formed on the sensitive layer, and a Ta layer is formed on the side of the absorption passivation layer away from the sensitive layer by using a magnetron sputtering process, as a pattern transfer layer, and the thickness of the pattern transfer layer is 100nm;

[0070] Utilize the first plasma etching to form a nanostructure on the side of the Ta layer away from the absorption passivation layer, wherein the etching conditions of the first plasma etching are as follows:

[0071] The etching gas pressure is 65mT, the upper radio frequency is 1600W, and the lower radio frequency is 40W. The etching gas includes C 4 f 6 , CO and Ar, C 4 f 6 The flow rate of CO is 10sccm, the flow rate of CO is 10sccm, and the flow rate of Ar is 250sccm;

[0072] Part or all of the Ta layer is etched ...

Embodiment 2

[0076] The preparation method of the infrared absorbing film of the present embodiment comprises the following steps:

[0077] form a sensitive layer;

[0078]Form an absorption passivation layer on the sensitive layer, and use ALD process to form a Ta layer on the side away from the sensitive layer of the absorption passivation layer, as a pattern transfer layer, and the thickness of the pattern transfer layer is 850nm;

[0079] Utilize the first plasma etching to form a nanostructure on the side of the Ta layer away from the absorption passivation layer, wherein the etching conditions of the first plasma etching are as follows:

[0080] The etching gas pressure is 297mT, the upper radio frequency is 3000W, and the lower radio frequency is 80W. The etching gas includes C 4 f 8 , CO and Ar, C 4 f 6 The flow rate of CO is 180sccm, the flow rate of CO is 185sccm, and the flow rate of Ar is 475sccm;

[0081] Part or all of the Ta layer is etched by the second plasma etching,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com