Method for patterning nanoparticle layer, quantum dot light-emitting device and display device

A quantum dot light-emitting, nano-particle technology, applied in nano-optics, chemical instruments and methods, luminescent materials, etc., can solve problems such as difficult to achieve, high resolution, and no breakthrough in QLED high-resolution patterning technology. Good performance, high-resolution effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

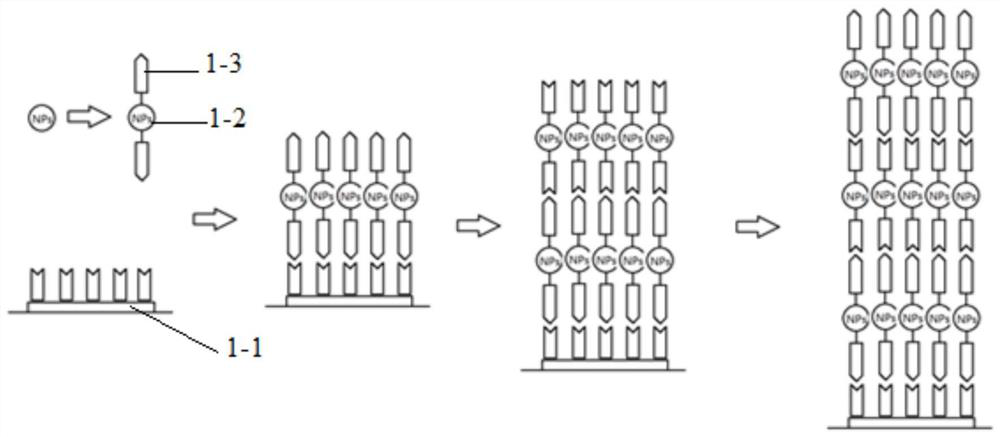

[0120] 1.1 Nanoparticle treatment

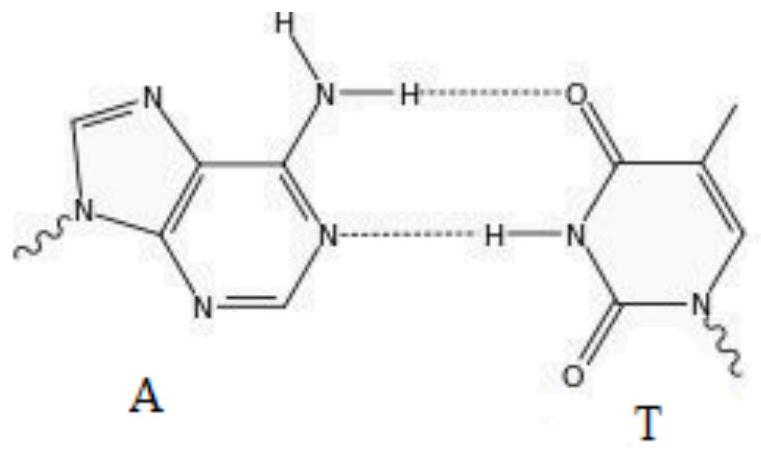

[0121] 1.1.1 Mix the ligand containing adenine (A) and the nanoparticle solution, precipitate after stirring, and centrifuge to obtain adenine-modified nanoparticles (A-NPs);

[0122] 1.1.2 The ligand containing thymine (T) and the nanoparticle solution were mixed, stirred, precipitated, and centrifuged to obtain thymine-modified nanoparticles (T-NPs).

[0123] 1.2 Nanoparticle deposition

[0124] 1.2.1 Chemically modify the substrate to obtain a substrate containing T on the surface; specifically:

[0125]1) Hydroxylation of the substrate: soak the glass substrate in the mixed washing solution of concentrated sulfuric acid and hydrogen peroxide (the volume ratio of concentrated sulfuric acid: hydrogen peroxide is 7:3), heat it to 80 degrees Celsius for 5 hours, and wash it with deionized water after the reaction , to obtain a hydroxylated glass substrate; 2) chemical modification: soak the substrate in a toluene solution (0.5mmol / L) conta...

Embodiment 2

[0131] 2.1 Quantum dot processing

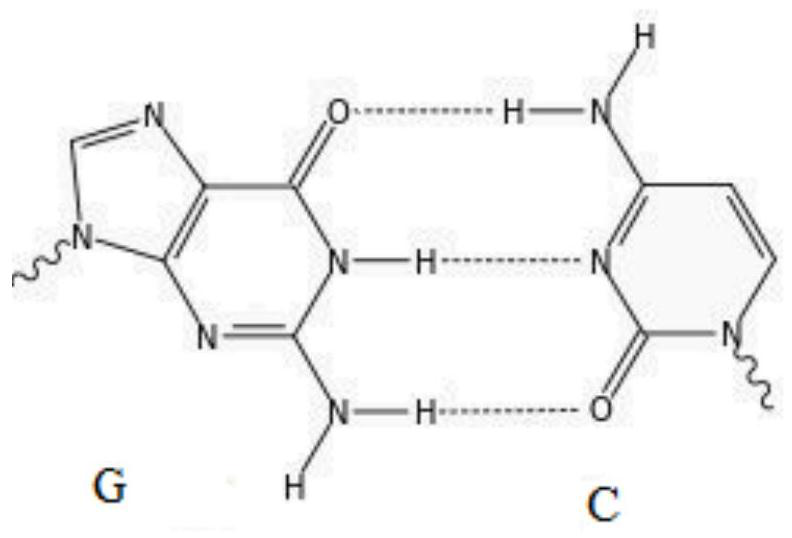

[0132] According to the scheme of 1.1.1, quantum dots 1, 2, and 3 were modified with ligands containing A, T, G, C, X, and Y bases, respectively, to obtain corresponding quantum dots A-NPs 1, T-NPs 1, G-NPs 2, C-NPs 2, X-NPs 3, Y-NPs 3.

[0133] 2.2 Substrate processing and deposition

[0134] 2.2.1 Use methods such as printing, transfer printing, and exposure to modify different preset regions of the substrate with bases containing T, C, and Y;

[0135] 2.2.2 Coating A-NPs on the modified substrate, and forming an A-NPs quantum dot layer in the T-modified preset area after assembly;

[0136] 2.2.3 Coating T-NPs on the substrate, the surface of A-NPs will continue to deposit T-NPs;

[0137] 2.2.4 Repeat the two steps 2.2.2 and 2.2.3 to form a NPs 1 quantum dot layer in the preset area modified by T, and no quantum dots are deposited in the positions modified by C and Y;

[0138] 2.2.5 Alternately coat G-NPs 2, C-NPs 2, X-NPs 3, and Y-NPs...

Embodiment 3

[0140] 3.1 Quantum dot processing

[0141] 3.1.1 Mix the ligand containing adenine (A) and the quantum dot solution, precipitate after stirring, and centrifuge to obtain adenine-modified quantum dots (A-NPs);

[0142] 3.1.2 Mix the ligand containing thymine (T) and the quantum dot solution, stir, precipitate, and centrifuge to obtain thymine-modified quantum dots (T-NPs).

[0143] 3.2 Substrate processing and deposition

[0144] 3.2.1 Coat zinc oxide quantum dots on the Qled substrate containing the pixel structure, anneal at 30mg / mL, 2000rpm, and 100°C for 30 minutes to obtain a zinc oxide film.

[0145] Print a solution (0.5mmol / L) containing 1H, 1H, 2H, 2H-perfluorododecyltrichlorosilane in the desired pixel, let it stand for 10 minutes, and rinse with toluene to obtain a C8F17 group containing the substrate.

[0146] The compound containing the base T and C8F17 group was dissolved in the solution (1 mg / mL), and the substrate was immersed in it at room temperature for 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com