Pickling agent applied for squab braised in brown sauce and pickling method using pickling agent

A kind of pickling preparation and technology of squab, which is applied in the field of braised squab preparation, can solve the problems of uneven pickling, too salty taste, long pickling time, etc., and achieve reasonable pickling time, high freshness, and uniform pickling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

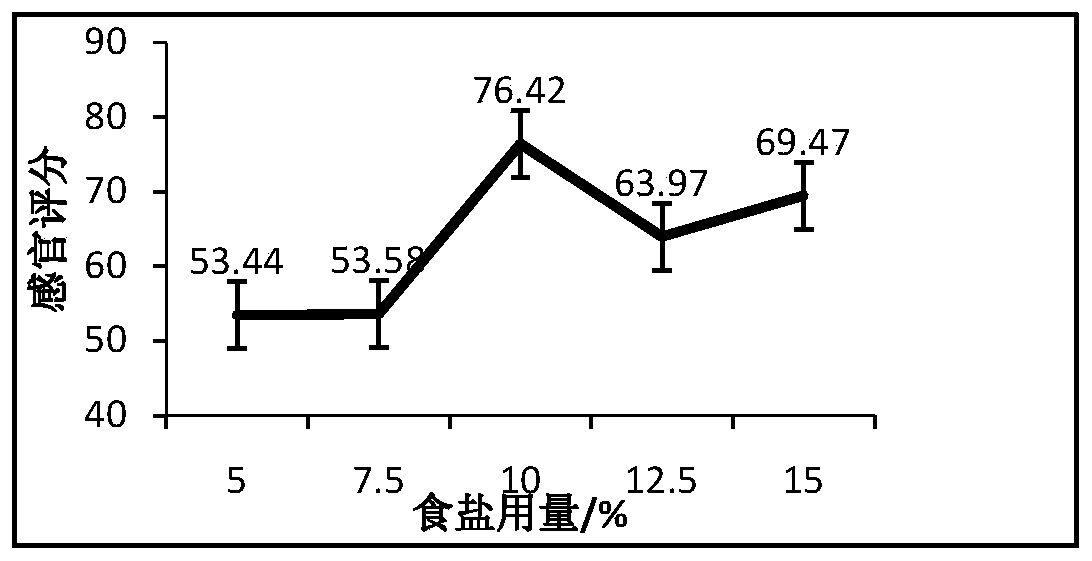

[0041] A pickling preparation applied to braised squab. Based on the mass of the squab, the mass of each component is 0.4% star anise, 0.15% pepper, 0.2% pepper, 0.5% cinnamon, 0.5% tangerine peel, and 0.1% bay leaf , 0.5% fennel, 0.5% licorice, 5% ginger, 1% soy sauce, 1% Hakka wine, 0.4% monosodium glutamate, fully mixed to obtain a pickling preparation.

Embodiment 2

[0043] (1) Raw material pretreatment method:

[0044] After washing the pigeons, drain the surface water, remove the feet, and blanch them in boiling water for later use;

[0045] (2) Blanching method:

[0046] First boil a large pot of boiling water and keep it boiling. Drain the surface water of the cleaned pigeons, quickly put them into boiling water, then pick them up and rinse them with running water to cool to room temperature. Rinse the blood stains on the surface and inside of the pigeons, and drain them. stand-by;

[0047] (3) Pickling method:

[0048] The salting preparation formula is according to the salting preparation of embodiment 1 gained;

[0049] Dry pickling method: Stir the pickle formula evenly, apply it evenly on the squab to marinate, then seal it with a sealing bag, put it in a large beaker for ultrasonic treatment, and process it for 30 minutes, then take it out and turn the raw material up and down once , so repeated 2-3 times. During the picklin...

Embodiment 3

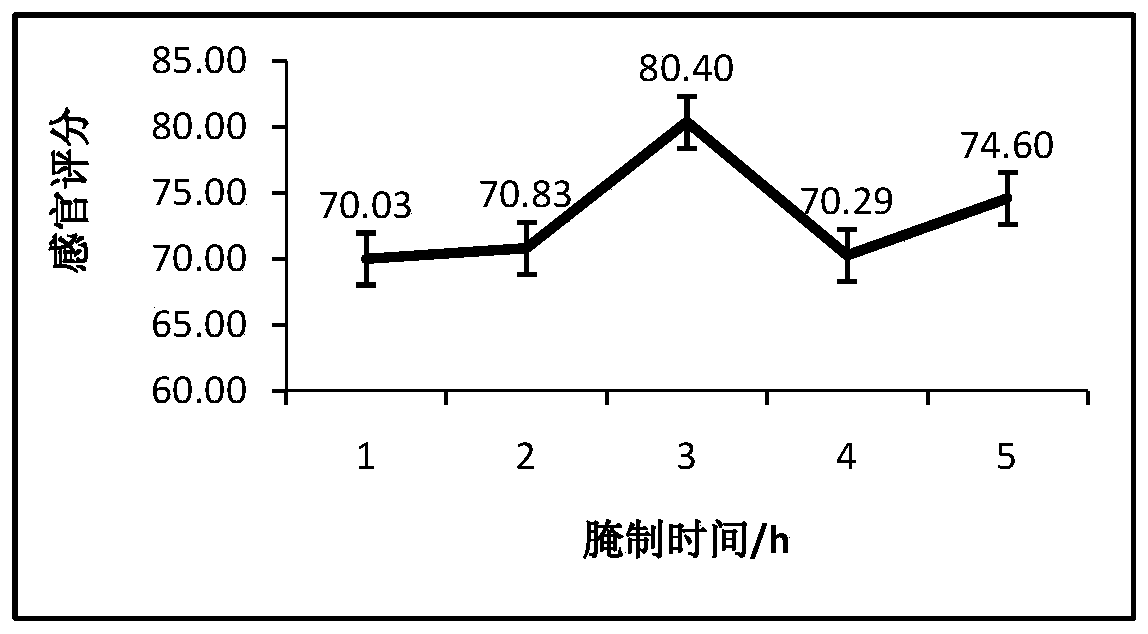

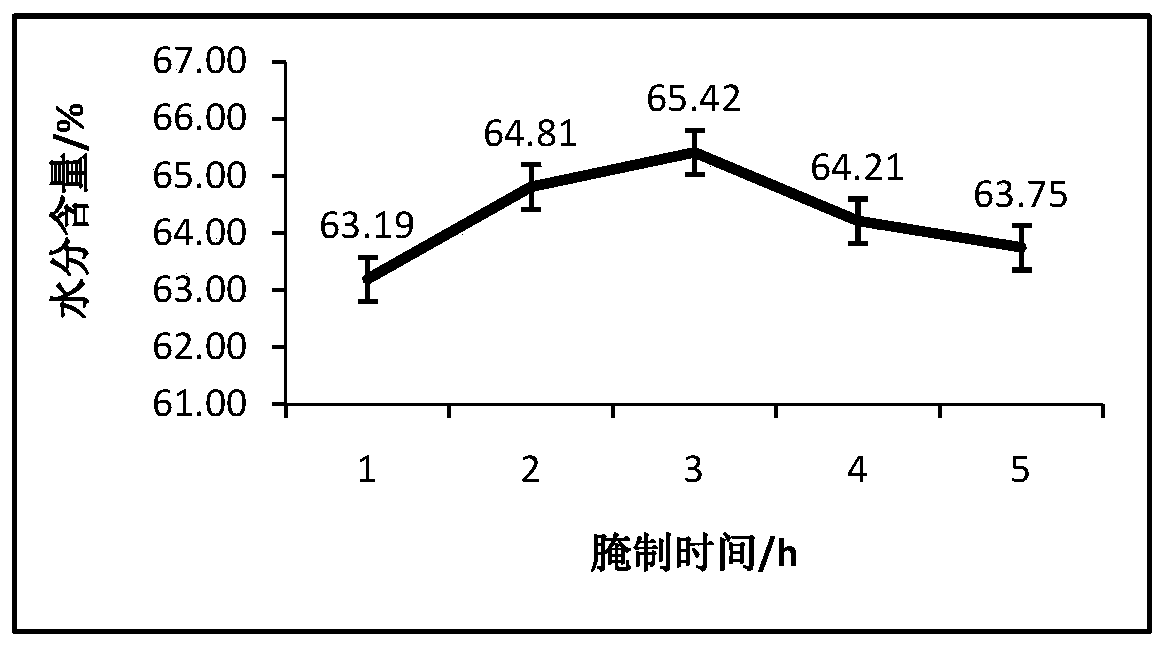

[0056] Embodiment 3: the result and analysis of different pickling time

[0057] Effects of pickling time on the sensory quality of braised squab as follows: figure 1 ,Depend on figure 1 It can be seen that the sensory score is relatively high when the pickling time is 3h. If the marinating time is too short, the marinating agent will not fully penetrate into the meat, and if the marinating time is too long, the meat will lose too much water, resulting in an overly salty taste. Braised squab with a marinating time of 3 hours is relatively the best in quality and is most popular with raters, so 2 hours, 3 hours, and 4 hours are selected as appropriate curing times.

[0058] Table 1 Effect of different pickling time on the color difference of braised squab

[0059]

[0060] It can be seen from Table 1 that when the pickling time is 2-4h, the color difference value increases with time, and when the pickling time is 4-5h, the color difference value decreases with the increas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com