A collection system prepared by w/o/w multiphase emulsion and its preparation method and application

A multiphase emulsion and system technology, applied in solid separation, flotation and other directions, can solve the problems of low yield of benzhydroxamic acid, large pollution, large amount of hydroxylamine, etc. effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

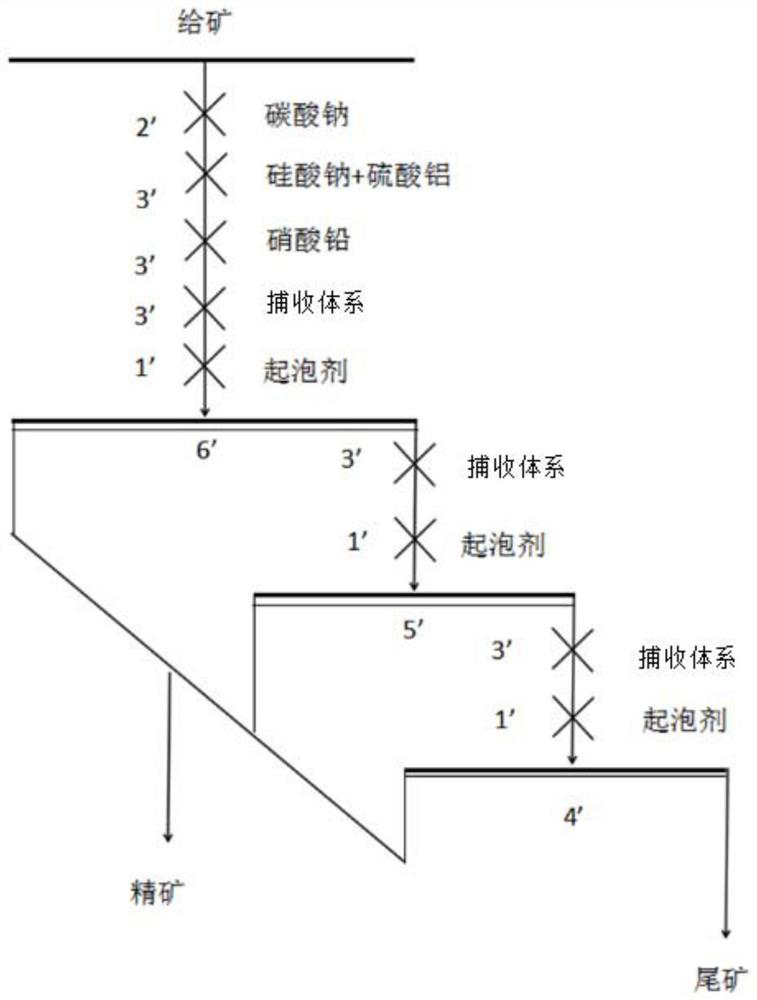

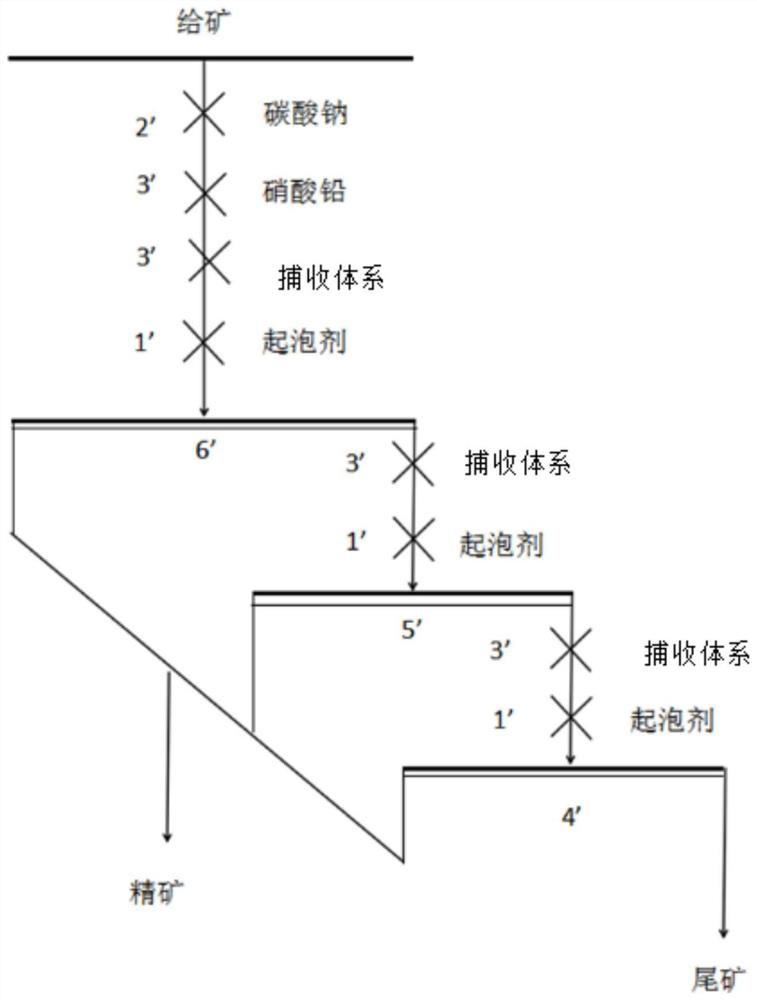

Method used

Image

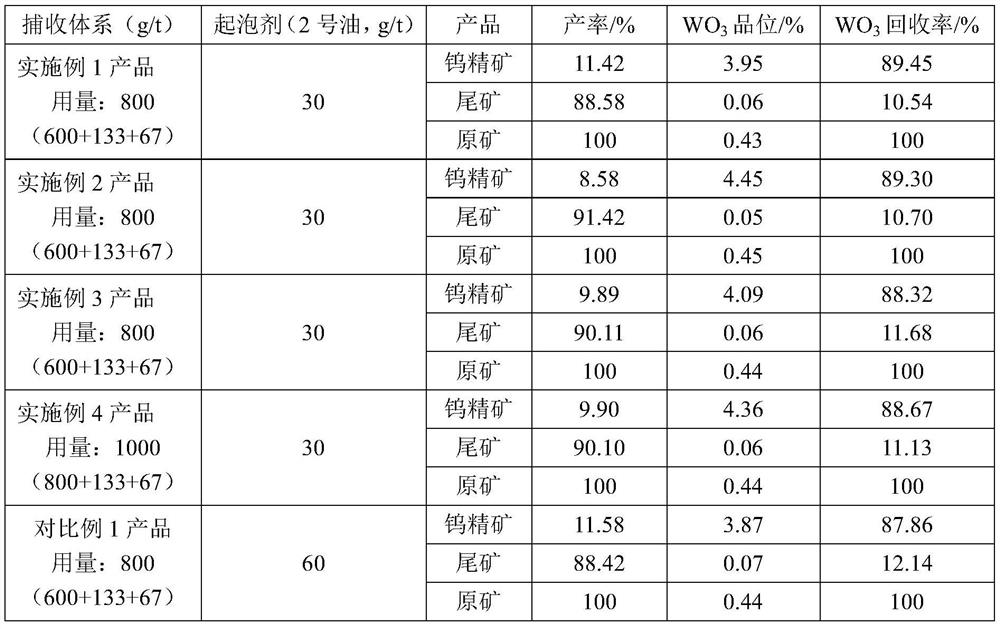

Examples

Embodiment 1

[0034] This embodiment provides a collection system, which is prepared by the following method.

[0035] In a 250 mL three-necked double-necked reaction flask equipped with a condenser, a stirrer and a thermometer, 20.0 g of methyl benzoate and 0.2 g of Span-80 were mixed, and 26 mL of 40% aqueous hydroxylamine hydrochloride was added dropwise. After the system is uniformly dispersed to form a water-in-oil emulsion, gradually add 24mL of 50% sodium hydroxide to form a W / O / W multi-phase emulsion system, control the temperature to 40±1°C, and react for 4h. After the reaction, add concentrated sulfuric acid until the pH of the solution is about 6, leave standstill to obtain 82.4g of product, obtain the content of benzohydroxamic acid of product by Kjeldahl method and be 22.5%, and the yield of benzohydroxamic acid is 93.4% %.

Embodiment 2

[0037] This embodiment provides a collection system, which is prepared by the following method.

[0038]In a 250 mL three-necked double-layer reaction flask equipped with a condenser, a stirrer and a thermometer, 20.0 g of methyl benzoate and 0.8 g of dodecyl glucoside were mixed, and 27 mL of 40% hydroxylamine hydrochloride aqueous solution was added dropwise. After the system is uniformly dispersed to form a water-in-oil emulsion, gradually add 25 mL of 50% sodium hydroxide to form a W / O / W multi-phase emulsion system, control the temperature at 42±1°C, and react for 3 hours. After the reaction finished, add concentrated sulfuric acid to the solution pH is about 6, leave standstill to obtain benzohydroxamic acid thick product 85.6g, obtain the content of the benzohydroxamic acid of product by the Kjeldahl nitrogen method be 21.7%, benzylhydroxamic acid The yield of xamic acid was 93.5%.

Embodiment 3

[0040] This embodiment provides a collection system, which is prepared by the following method.

[0041] In a 250 mL three-necked double-necked reaction flask equipped with a condenser, a stirrer and a thermometer, 20.0 g of methyl benzoate and 1.6 g of Triton X-200 were mixed, and 28 mL of a 40% aqueous solution of hydroxylamine hydrochloride was added dropwise. After the system is uniformly dispersed to form a water-in-oil emulsion, gradually add 29 mL of 50% sodium hydroxide to form a W / O / W multi-phase emulsion system, control the temperature at 45±1°C, and react for 2.5 hours. After the reaction finished, add concentrated sulfuric acid to the solution pH is about 6, leave standstill to obtain benzohydroxamic acid thick product 88.4g, obtain the content of the benzohydroxamic acid of product by Kjeldahl method be 20.3%, benzylhydroxamic acid The yield of xamic acid was 90.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com