Dried tomato cut petals drying laying platform

A technology of tomato dried and sliced, applied in loading/unloading, metal processing, food science and other directions, can solve the problems of high labor intensity, high production cost, tomato rubbing and squeezing, and large loss, etc., and achieves a high degree of automation and is suitable for Wide-ranging, productive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

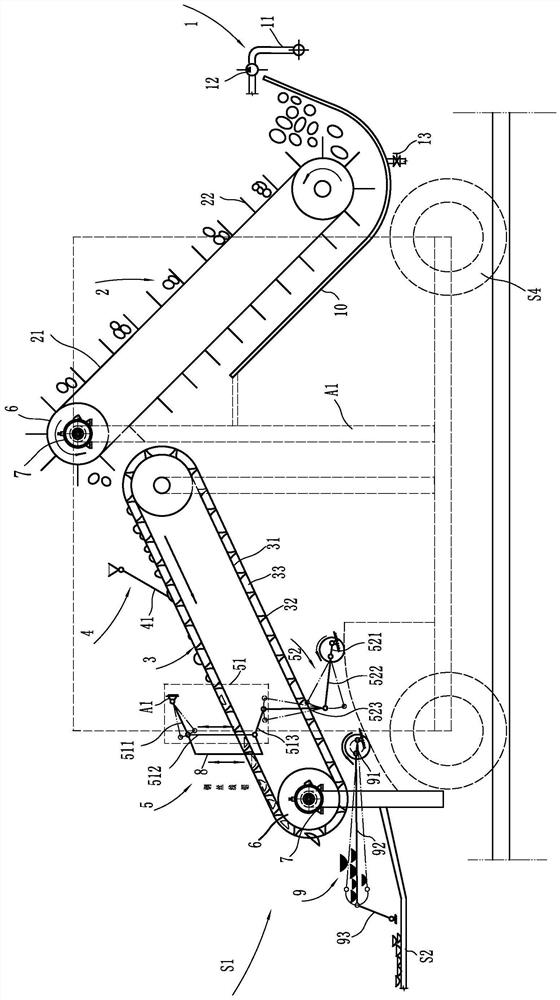

[0042] Embodiment 1: refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 7 and Figure 8

[0043] The scheme provides a platform for drying and laying dried tomato petals, including a tomato petal cutting device S1 and a paving platform S2, and a drying tray S3-2 is arranged on the paving platform S2;

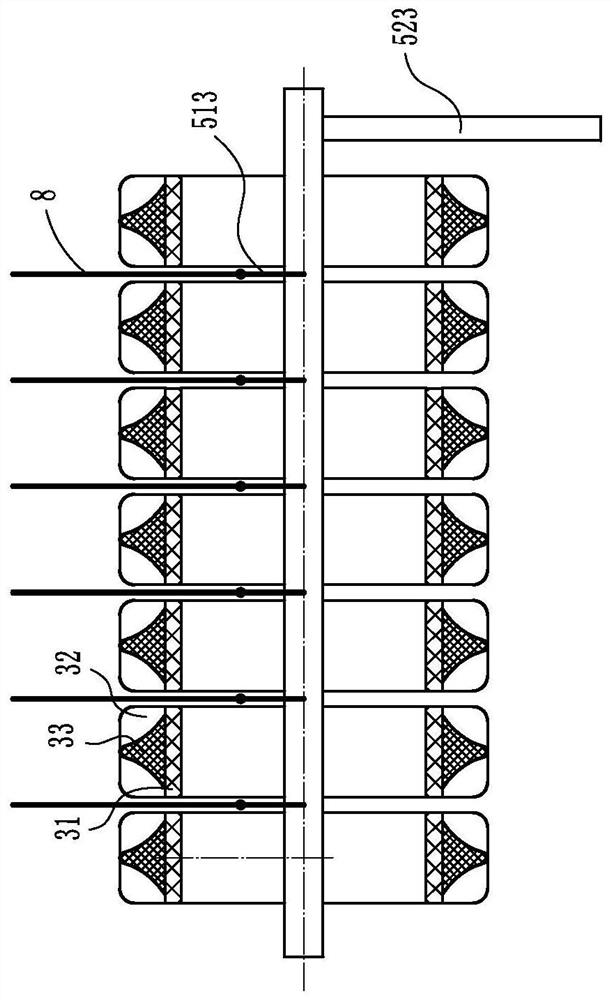

[0044] The tomato flap cutting device S1 is mainly composed of a frame A1, a transfer mechanism 2, a conveying mechanism 3, a paving mechanism 4 and a cutting mechanism 5;

[0045] The transfer mechanism 2 is obliquely arranged and partially immersed in the material tank 10 to form a cleaning mechanism 1. The transfer mechanism 2 is mainly composed of a power unit 7, at least two rollers 6, a conveyor chain 21 and a scraper 22. The conveyor chain 21 is arranged on at least two A conveying body comprising a feeding end and a discharging end is constituted on the first drum 6, and the scraper 22 is a plate or a row-shaped body erected on the conveying chain 21 an...

Embodiment 2

[0071] Embodiment 2: refer to Figure 7

[0072] Compared with Embodiment 1, the difference is that the paving platform S2 is connected end to end to form a circular closed body, so that the tomato flap cutting device S1 can move on the paving platform S2 to perform circular periodic operations.

Embodiment 3

[0073] Embodiment 3: refer to figure 1 and Figure 9

[0074] Compared with Embodiment 2, the difference is that a laying mechanism 9 is also provided; the laying mechanism 9 is arranged on the discharge end of the conveyor belt 31 and fixed with the frame A1, which evenly lays the sliced tomatoes on the On the paving platform S2; the paving platform S2 is arranged on the lower part of the discharge end of the paving mechanism 9; the setting of the paving mechanism 9 can pave the output of the tomato flap through the output of the tomato flap device S1 conveyor belt 31 On the paving platform S2, effectively avoiding the accumulation of tomato slices on the paving platform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com