A kind of production method of tear-resistant woven label trademark

A production method and tear-resistant technology, which are applied in chemical instruments and methods, cutting and weaving of textile materials, etc., can solve the problems of selvedge stiffness, easy to hurt human skin, etc., achieve good flame retardant effect, improve human micro Circulation, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

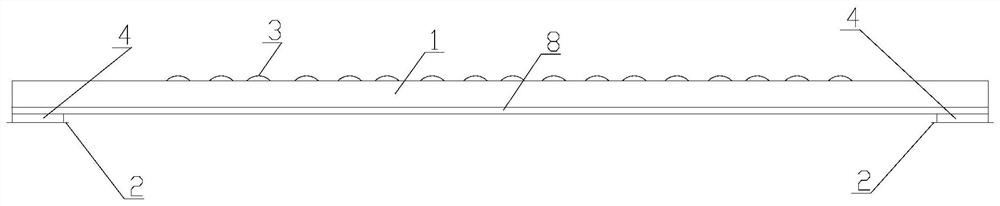

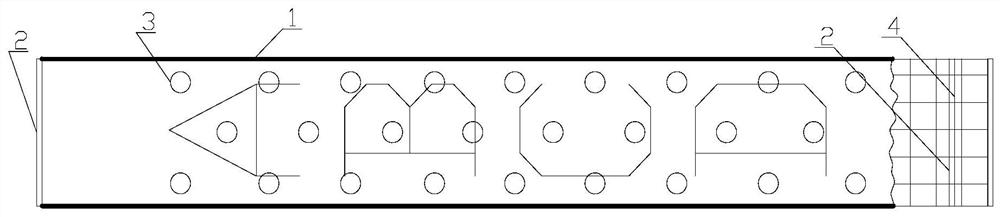

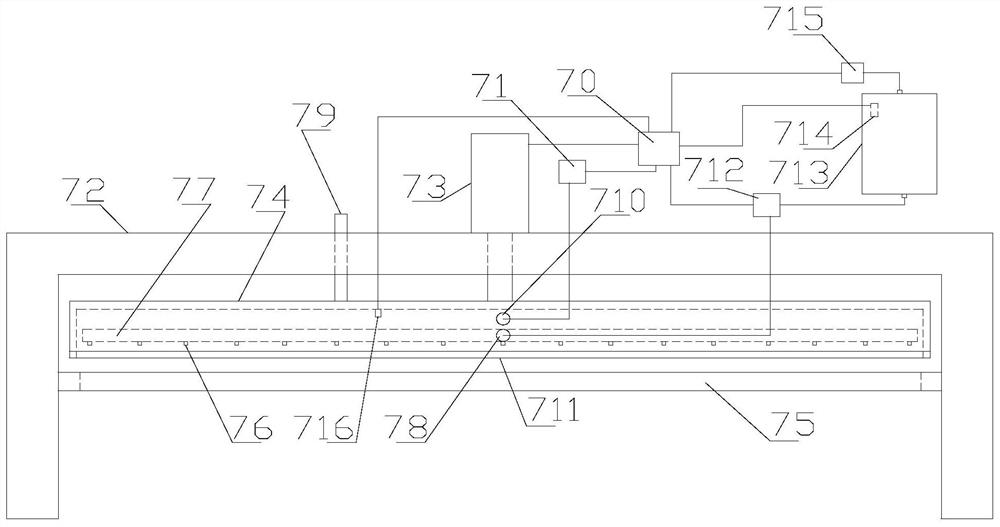

[0029]Seefigure 1 ,figure 2 ,image 3 withFigure 4According to a tear-woven tramark of the tear-woven, a woven tramark body 1 and a shaped liner layer 8, and the back surface of the weaving main body 1 is provided with a forming lining layer 8, and the woven trademark main body 1 is from the warp yarn and the weft yarn. Silk, the warp yarn is composed of a coating yarni having a core yarn I and a spiral to the core yarn I, which is blended by spandex fibers, pearl fibers and silver ion fibers. The coated yarn is blended from a plurality of interlayer aramid fibers, silver ion fibers, and polyester fibers, and the weft yarn is composed of a core yarn II and a spiral to coated a coated yarn II. The core yarn II is twisted by two core yarns, wherein one core yarn is blended by spandex fibers, pearl fibers and silver ion fibers, and the other core yarn II is made of at least two polypropylene yarns. The wire is twisted, and the coated yarn II is blended from a plunge aramid fiber, a silv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com