Cyanobacteria integration treatment method and equipment

A treatment method, cyanobacteria technology, applied in chemical instruments and methods, sludge treatment, pyrolysis treatment of sludge, etc., can solve the problems of stacking algae mud, secondary pollution of water body, perishable and odorous, etc., and achieve cost savings in treatment , volume reduction, avoiding the effect of easy to rot and smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

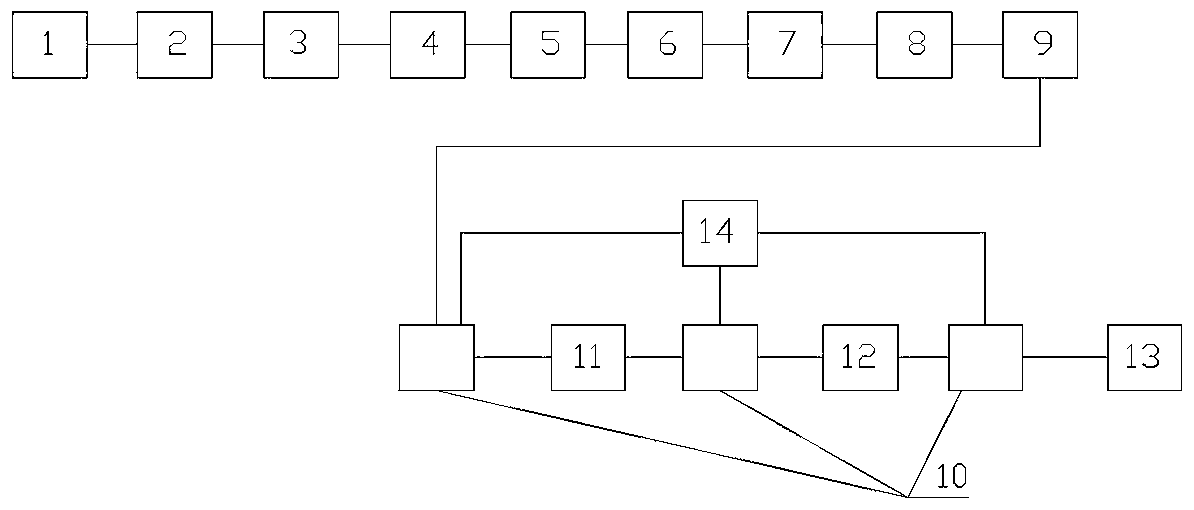

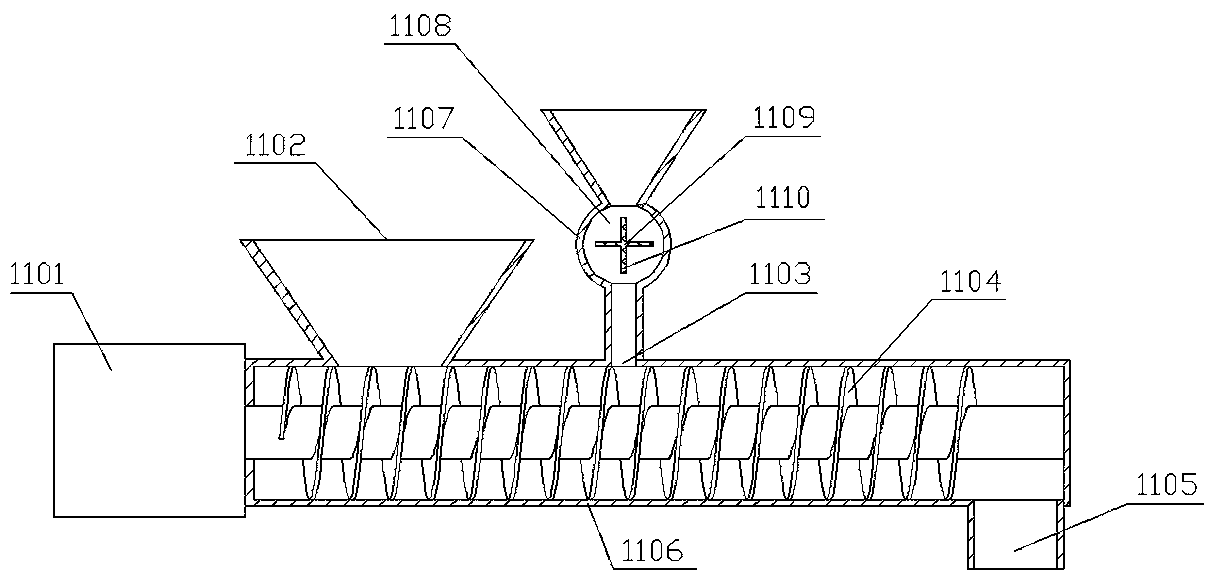

[0012] The cyanobacteria integrated processing method of the present invention comprises the following steps:

[0013] First pressurize the salvaged algae slurry with a solid content of 1-5% to make the pressure reach 0.5-1Mp;

[0014] Then, according to the weight ratio of algae pulp: flocculant = 20:1, the flocculant is added to the pressurized algae pulp to flocculate the algae pulp;

[0015] After that, dehydrate the flocculated algae slurry to obtain algae mud with a moisture content of 78-82%;

[0016] Afterwards, according to the weight ratio of algae mud: conditioning agent=15:1, add conditioning agent in algae mud and mix uniformly, algae mud is conditioned, modified;

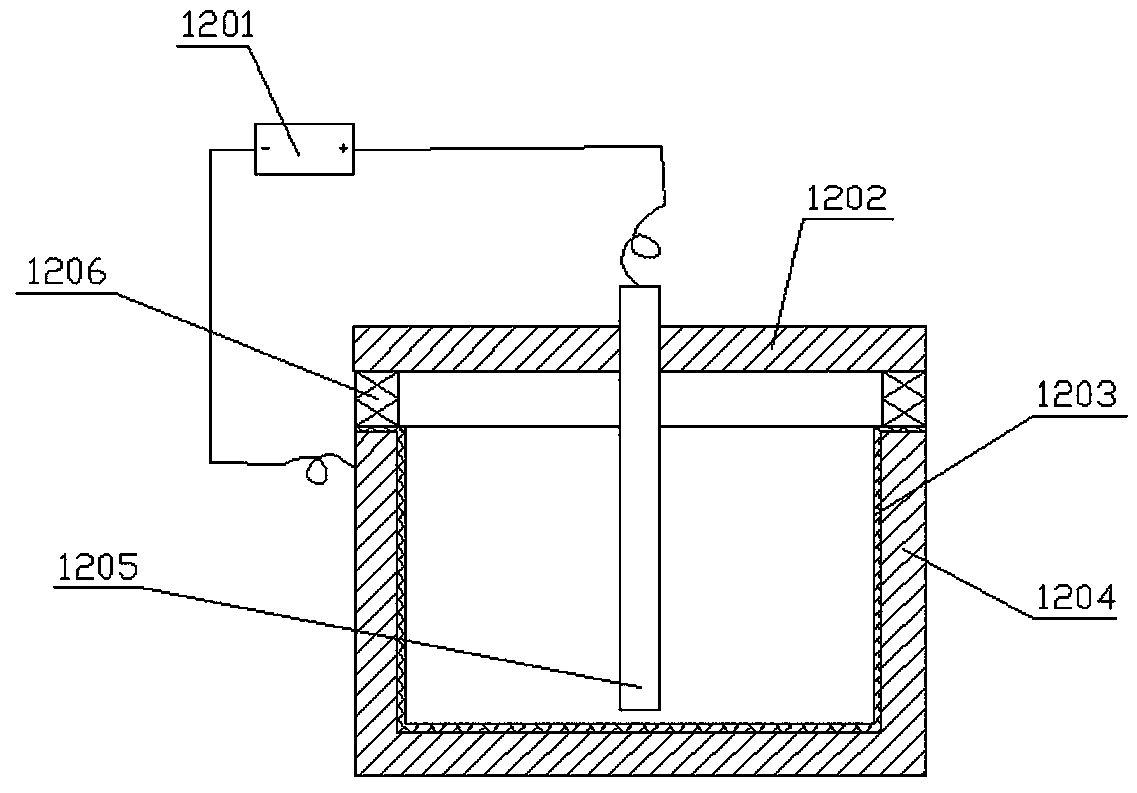

[0017] Afterwards, the modified algae mud is deeply dehydrated to reduce the moisture content of the algae mud to below 50%;

[0018] Finally, pyrolyze and carbonize the algae mud with a moisture content of less than 50% to reduce its weight to one-thirtieth the following.

[0019] Wherein, the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com