Oil performance improver, and preparation method and application thereof

A technology of improver and performance, applied in the petroleum industry, fuel additives, liquid carbon-containing fuels, etc., can solve the problems of insignificant pour point depressing effect, poor susceptibility of 0# diesel oil, etc., to improve low temperature flow performance, enhance solubility, Obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

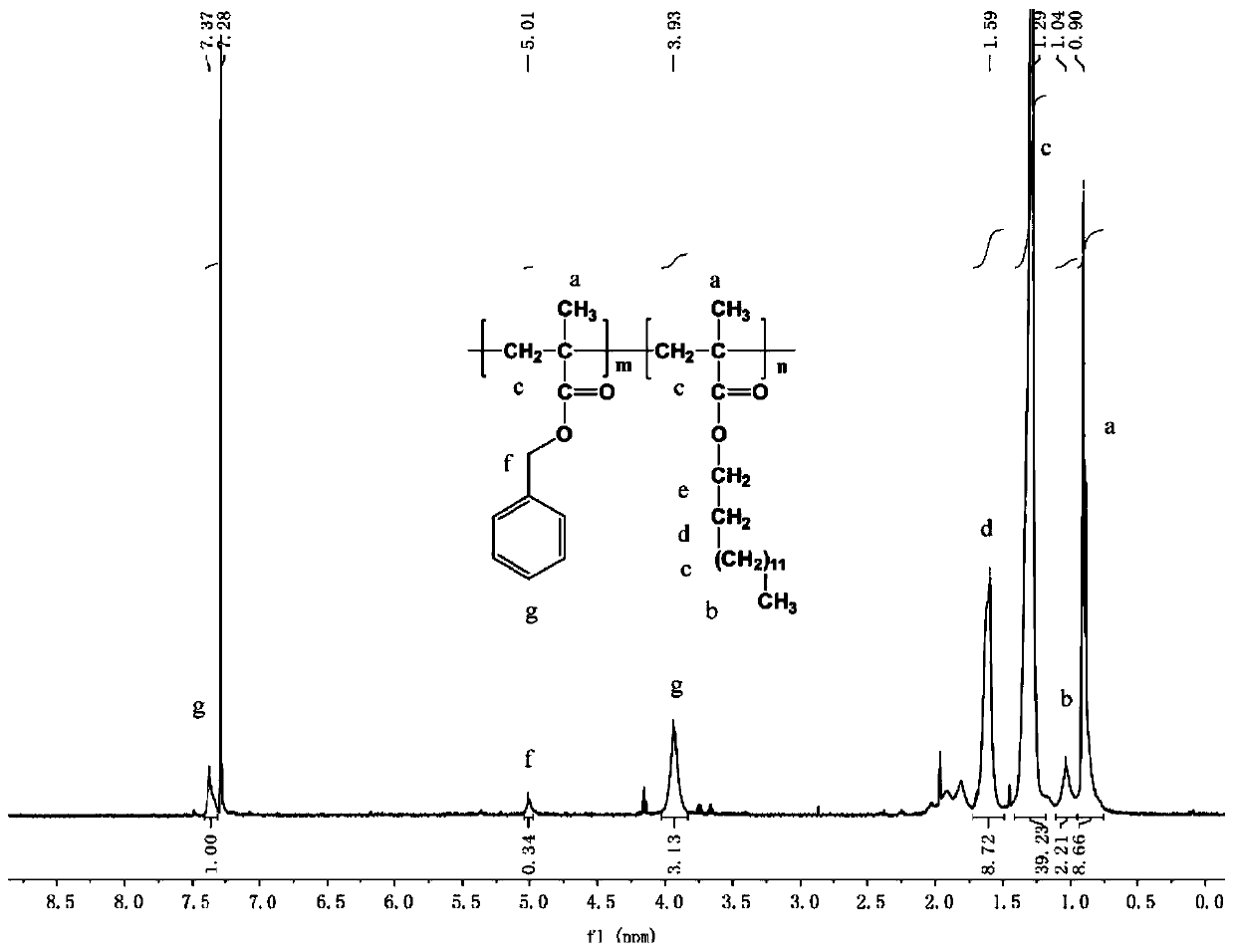

Method used

Image

Examples

Embodiment 1

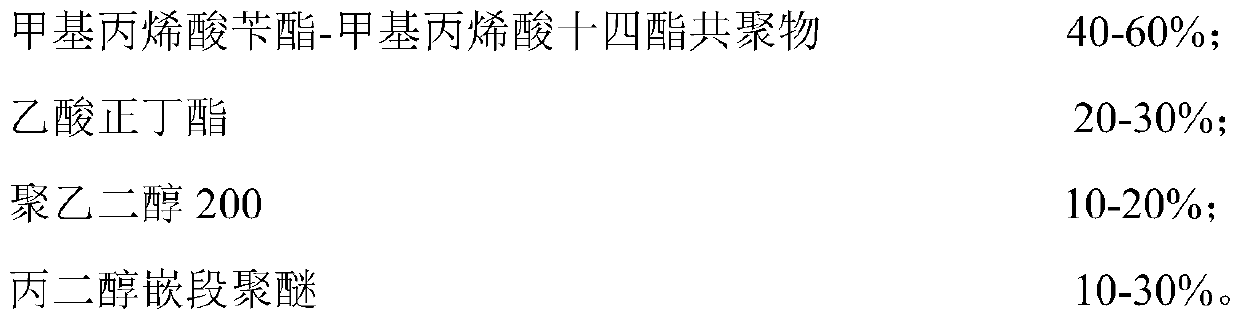

[0043] A kind of oil performance improver, by mass percentage, it is made up of following components:

[0044]

[0045] The preparation method of the described oil performance improver is as follows: benzyl methacrylate-tetradecyl methacrylate copolymer, ethyl acetoacetate, dimethyl phthalate and cyclohexane in proportion at 25°C Mix and stir evenly at a certain temperature, and ultrasonically disperse for 20 minutes to obtain the oil performance improver.

[0046] For the application of the above-mentioned oil performance improver in diesel oil pour point depressing, the oil performance improver is added to 60 g of Songjiang 0# diesel oil in a mass of 0.1%, and after mixing and stirring at a temperature of 50°C, ultrasonically disperses for 15 minutes, namely Diesel oil containing the diesel oil pour point depressant composition is obtained.

[0047] The condensation point and cold filter point of the commercially available 0# diesel containing the above-mentioned oil per...

Embodiment 2

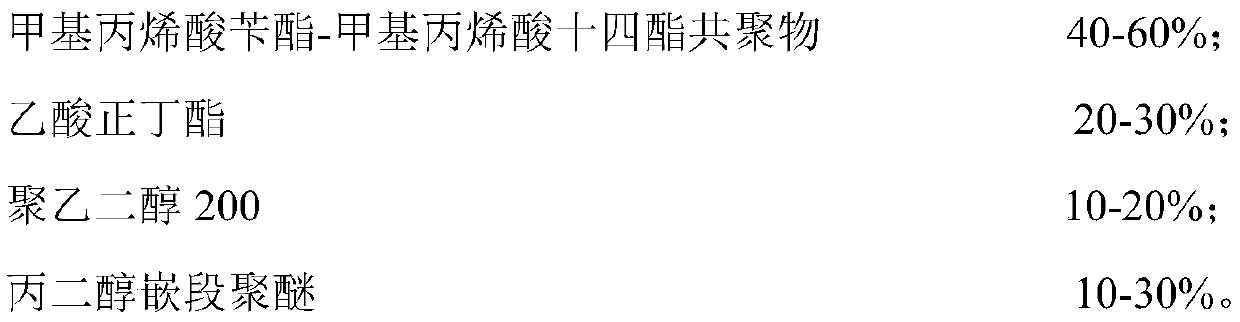

[0049] A kind of oil performance improver, by mass percentage, it is made up of following components:

[0050]

[0051] The preparation method of the described oil performance improver is as follows: benzyl methacrylate-tetradecyl methacrylate copolymer, ethyl acetoacetate, dimethyl phthalate and cyclohexane in proportion at 25°C Mix and stir evenly at a certain temperature, and ultrasonically disperse for 20 minutes to obtain the oil performance improver.

[0052] For the application of the above-mentioned oil performance improver in diesel oil pour point depressing, the oil performance improver is added to 60 g of Songjiang 0# diesel oil in a mass of 0.1%, and after mixing and stirring at a temperature of 50°C, ultrasonically disperses for 15 minutes, namely The diesel oil containing the diesel oil point depressant composition is obtained.

[0053] The condensation point and cold filter point of the commercially available 0# diesel oil containing the above-mentioned diesel...

Embodiment 3

[0055] A kind of oil performance improver, by mass percentage, it is made up of following components:

[0056]

[0057] The preparation method of the described oil performance improver is as follows: benzyl methacrylate-tetradecyl methacrylate copolymer, ethyl acetoacetate, dimethyl phthalate and cyclohexane in proportion at 25°C Mix and stir evenly at a certain temperature, and ultrasonically disperse for 20 minutes to obtain the oil performance improver.

[0058] For the application of the above-mentioned oil performance improver in diesel oil pour point depressing, the oil performance improver is added to 60 g of Songjiang 0# diesel oil in a mass of 0.1%, and after mixing and stirring at a temperature of 50°C, ultrasonically disperses for 15 minutes, namely The diesel oil containing the diesel oil point depressant composition is obtained.

[0059] The condensation point and cold filter point of the commercially available 0# diesel oil containing the above-mentioned dies...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com