Boron-nitrogen type lubricating oil composition, preparation method thereof, and trace lubricating oil prepared from composition

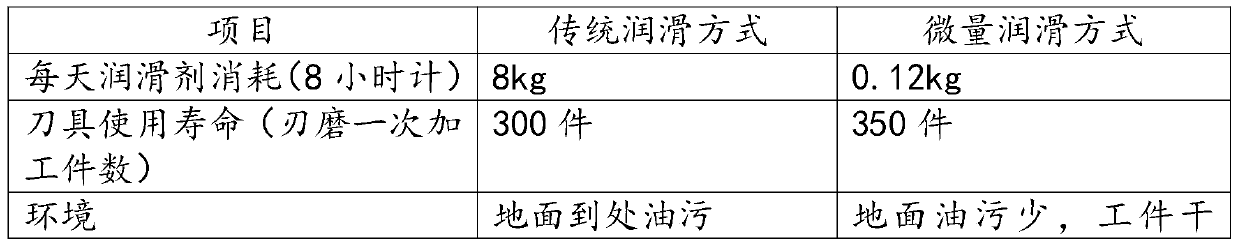

A lubricating oil composition and lubricating oil technology, applied in the field of lubrication, can solve the problems of large amount of lubricant used, affecting the health of operators, unfriendly sulfur-containing and chlorine-containing additives, etc., and achieve good lubricity and extreme pressure resistance. Grinding, environmental protection effect is remarkable, good degradability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1: Weigh 564.92 g (1 mol) of dimer acid and 149.19 g (1 mol) of triethanolamine and add them together into a stirrer, stir and heat to 120° C., and fully react for 1 hour to obtain a dimer acid triethanol amide.

[0030] Step 2: Weigh 30.92 g (0.5 mol) of boric acid and add it to the stirrer of Step 1, keep it at 120 ° C for 3 hours, add 10 g of hydroxyethylethanolamine and continue stirring for about 1 hour to filter, which is the boron nitrogen type lubricating oil composition.

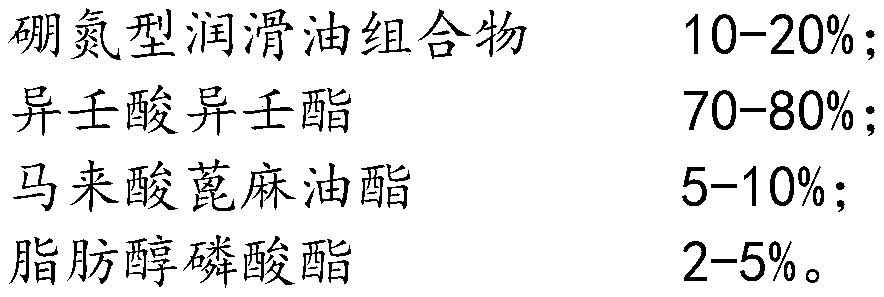

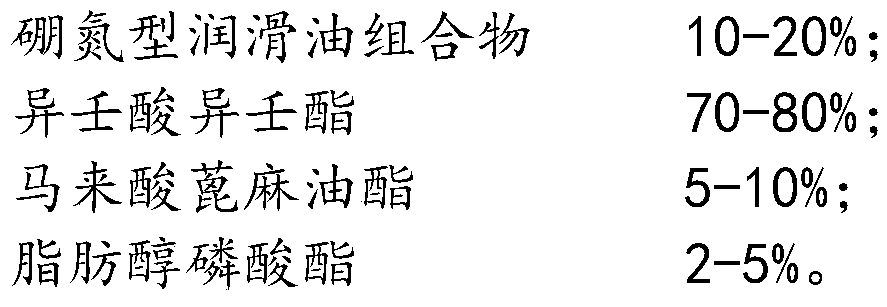

[0031] Weigh 200g of the above-prepared boron-nitrogen type lubricating oil composition, 700g of isononyl isononanoate, 50g of castor oil maleate, and 50g of monooleyl phosphate, and mix and stir at 50°C until it becomes transparent. Minimal quantity lubricant.

[0032] The preparation method of the above-mentioned castor oil maleate: Weigh 929.26g (1mol) of castor oil and 116.07g (1mol) of maleic acid into the reaction kettle together, stir and heat to 220°C, fully react for 6 hours, an...

Embodiment 2

[0034] Step 1: Weigh 282.46 g (0.5 mol) of dimer acid and 149.19 g (1 mol) of triethanolamine and add them together into a stirrer, stir and heat to 100° C., and fully react for 2 hours to obtain a dimer acid triethanol amide.

[0035] Step 2: Weigh 20.61 g (0.33 mol) of boric acid and add it to the stirrer of Step 1, keep it at 100°C for 4 hours, add 8 g of hydroxyethylethanolamine and continue stirring for about 1 hour to filter, which is boron nitrogen type lubricating oil composition.

[0036] Weigh 100g of the above-prepared boron-nitrogen type lubricating oil composition, 780g of isononyl isononanoate, 100g of castor oil maleate, and 20g of dioleyl alcohol phosphate, and mix and stir at 60°C until it becomes transparent. Minimal quantity lubricant.

[0037] The preparation method of the above-mentioned castor oil maleate: Weigh 929.26g (1mol) of castor oil and 232.14g (2mol) of maleic acid into the reaction kettle together, stir and heat to 200°C, fully react for 8 hours...

Embodiment 3

[0039] Step 1: Weigh 847.38 g (1.5 mol) of dimer acid and 149.19 g (1 mol) of triethanolamine and add them together into a stirrer, stir and heat to 110° C., and fully react for 1.5 hours to obtain a dimer acid triethanol amide.

[0040] Step 2: Weigh 24.73g (0.4mol) of boric acid and add it to the stirrer of Step 1, keep it at 110°C for 3.5 hours, add 8g of hydroxyethylethanolamine and continue to stir for about 1 hour to filter, which is the boron nitrogen type lubricating oil composition.

[0041] Weigh 150g of the above-prepared boron-nitrogen type lubricating oil composition, 750g of isononyl isononanoate, 70g of castor oil maleate, and 30g of trioleyl phosphate, and mix and stir at 40-50°C until it becomes transparent. A micro-quantity lubricant.

[0042] The preparation method of above-mentioned castor oil maleate: take castor oil 929.26g (1mol), maleic acid 174.11g (1.5mol), 20g phosphoric acid (concentration 50%) and add in the reactor together, stir and heat to 210 ℃...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com