Prussian blue-based enzyme-free uric acid sensor and preparation method thereof

A Prussian blue and sensor technology, applied in the field of electrochemistry, can solve problems such as increased production costs, complicated preparation steps, and electrode sheet failure, and achieve the effects of cost saving, simple preparation process, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

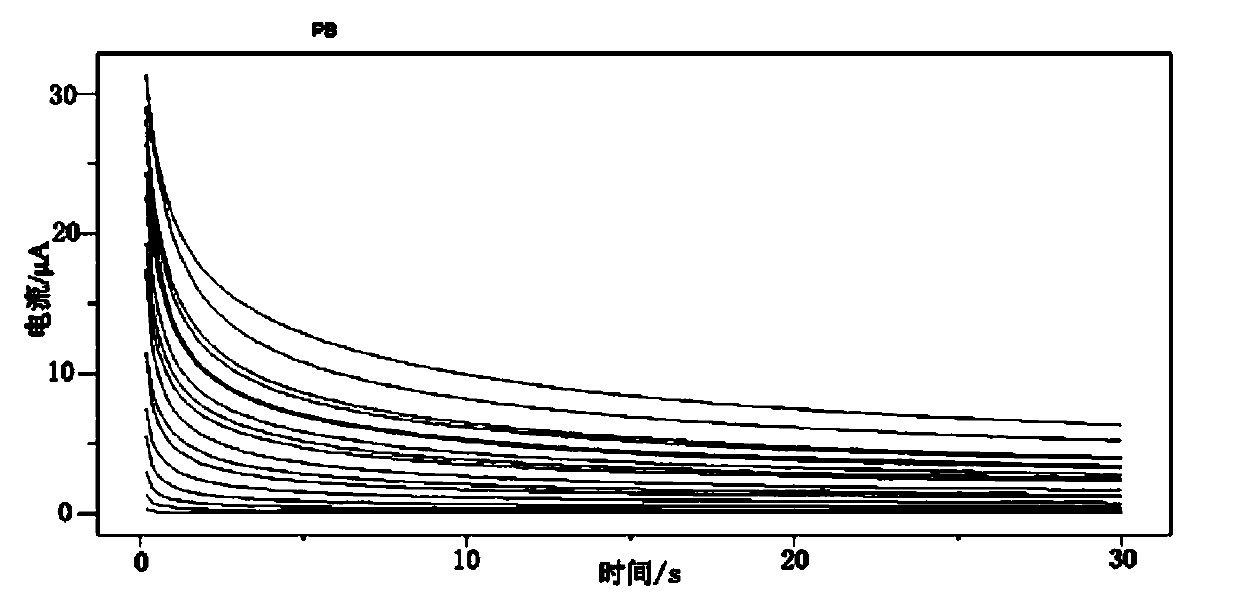

Embodiment 1

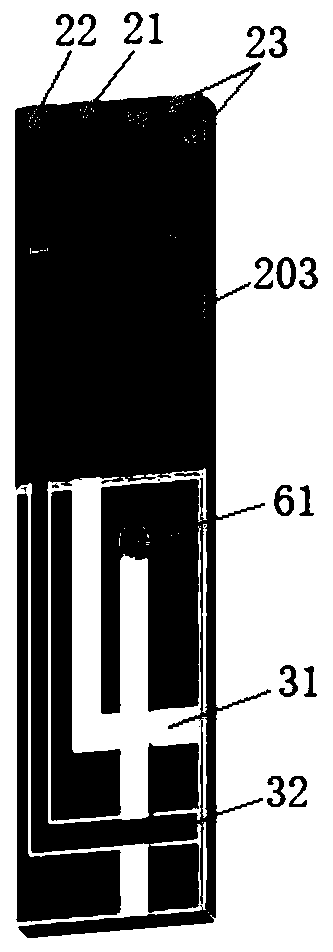

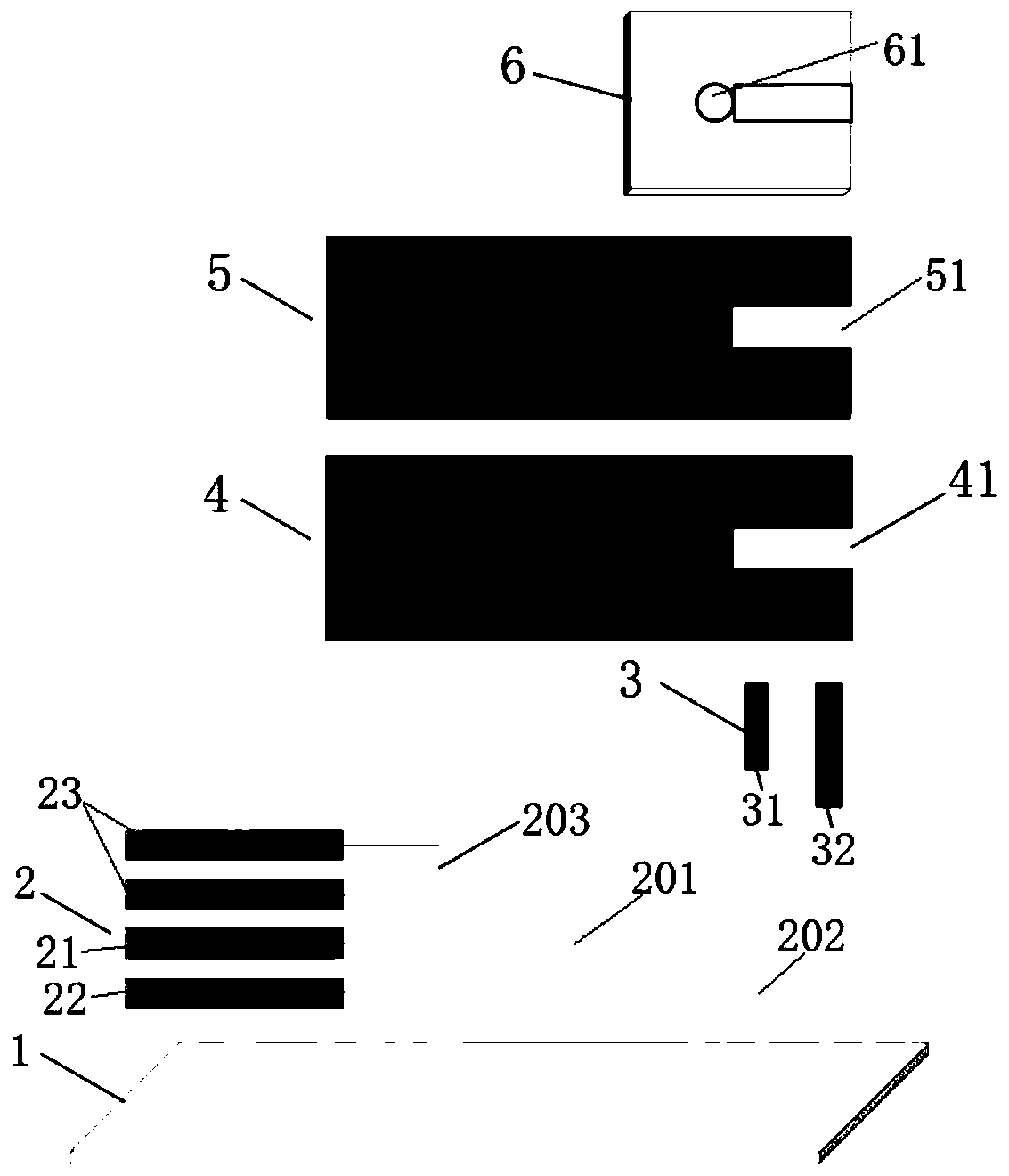

[0061] Such as figure 1 and figure 2 As shown, an enzyme-free uric acid sensor based on Prussian blue includes a substrate 1, a wire layer 2, an electrode layer 3, an insulating layer 4, a double-sided adhesive layer 5 and a hydrophilic film layer 6 sequentially stacked. Electrode layer comprises opposite electrode 31 and working electrode 32, and working electrode 32 is the Prussian blue carbon paste coating on the substrate, and Prussian blue carbon paste is mixed by Prussian blue (PB) powder and carbon paste. The mass fraction of Prussian blue in the Prussian blue carbon paste is 0.5%. Prussian blue is used to detect uric acid. The counter electrode 31 is a silver chloride coating on the substrate. The mass fraction of Prussian blue refers to the percentage of Prussian blue mass in the total mass of Prussian blue carbon paste. The counter electrode and the working electrode are parallel, and the counter electrode and the working electrode are perpendicular to the axis ...

Embodiment 2

[0079] The enzyme-free uric acid sensor based on Prussian blue prepared in this example has the same structure as the enzyme-free uric acid sensor in Example 1 except that the mass fraction of Prussian blue in the Prussian blue carbon slurry is 3.5%.

[0080] The preparation method of the enzyme-free uric acid sensor based on Prussian blue in the present embodiment comprises the following steps in turn:

[0081] 1) Put the PET substrate in pure water for ultrasonic cleaning for 15 minutes, and put it in an oven at 90°C for 30 minutes to dry.

[0082] 2) Use silver chloride paste to print the wire layer and the counter electrode on the surface of the substrate, put them in an oven at 120°C and dry for 15 minutes; the wire layer includes electrode terminals, two identification terminals, the first wire and the second wire.

[0083] 3) Prussian blue powder is added in the carbon slurry to mix and prepare Prussian blue carbon slurry, the mass fraction of Prussian blue in the Pruss...

Embodiment 3

[0090] The enzyme-free uric acid sensor based on Prussian blue prepared in this example has the same structure as the enzyme-free uric acid sensor in Example 1 except that the mass fraction of Prussian blue in the Prussian blue carbon slurry is 5%.

[0091] In this embodiment, the preparation method of the enzyme-free uric acid sensor based on Prussian blue comprises the following steps in turn:

[0092] 1) Put the PET substrate in pure water for ultrasonic cleaning for 15 minutes, and put it in an oven at 90°C for 30 minutes to dry.

[0093] 2) Use silver chloride paste to print the wire layer and the counter electrode on the surface of the substrate, put them in an oven at 120°C and dry for 15 minutes; the wire layer includes electrode terminals, two identification terminals, the first wire and the second wire.

[0094] 3) Prussian blue powder is added in the carbon slurry and mixed to prepare Prussian blue carbon slurry, the mass fraction of Prussian blue in the Prussian bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com