Saturated steam direct heating and puffing tank and food puffing and processing technology

The technology of puffing tank and steam is applied in the field of food puffing, which can solve the problems of low final temperature of food heating, large loss of nutrients, affecting puffing effect, etc., so as to achieve the effects of short time consumption, less nutrient loss and avoiding heat loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

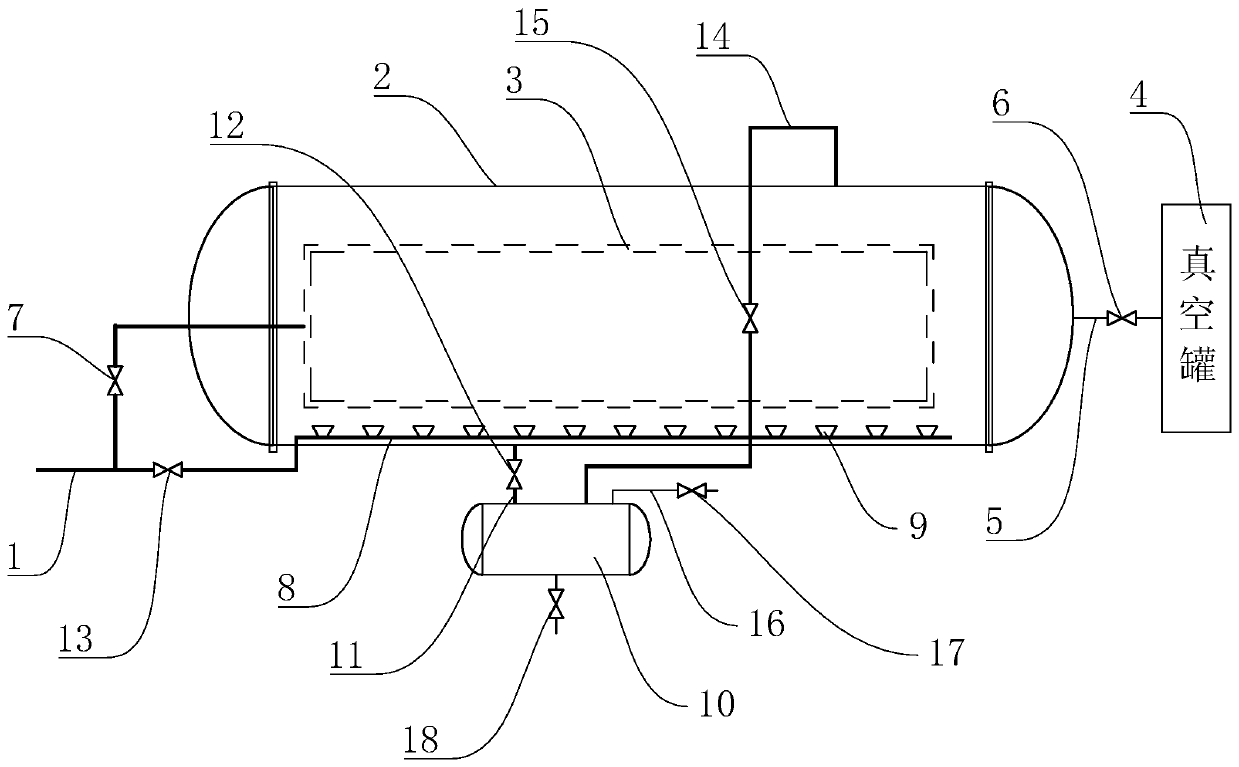

[0028] refer to figure 1 , a saturated steam directly heated expansion tank, including a steam pipe 1, an expansion tank body 2 and a heating shelf 3 inside the expansion tank body 2, the steam pipe 1 penetrates the expansion tank body 2 and is fixedly connected with the heating shelf 3. A vacuum tank 4 is arranged on one side of the expansion tank body 2, a vacuum tube 5 is fixedly connected between the vacuum tank 4 and the expansion tank body 2, and a vacuum valve 6 is installed on the vacuum tube 5. An indirect steam heating valve 7 is installed between the heating shelf 3 and the steam pipe 1, and the steam pipe 1 is fixedly connected with a steam nozzle main pipe 8 located inside the expansion tank body 2, and a plurality of steam nozzles 9 are installed on the steam nozzle main pipe 8, and the steam The spraying direction of the spray head 9 faces the inner wall of the expansion tank body 2 and is arranged obliquely upward.

[0029] A direct steam valve 13 is installed...

Embodiment 2

[0031] Using a kind of food puffing processing technology in the first embodiment, put the pretreated food into the puffing tank body 2, open the direct steam valve 13 and the indirect steam heating valve 7. After using the saturated steam to heat the food to the puffing temperature, close the direct steam valve 13, open the vacuum valve 6, and carry out puffing treatment. Subsequently, open the drain valve 12 and the pressure balance valve 15, let the steam condensed water in the expansion tank body 2 be discharged to the condensed water tank 10, after exhausting the steam condensed water in the expansion tank body 2, close the drain valve 12 and the pressure balance valve 15. At the same time, the opening degree of the indirect steam heating valve 7 is controlled, and the food is vacuum-dried at a certain temperature until the moisture drops to a certain value. Close the indirect steam heating valve 7 and the vacuum valve 6, and cool the shipment.

Embodiment 3

[0033] Using a sweet potato dry puffing process in Example 2: after pretreatment of the sweet potato (adjust the moisture content to 25% to 30%, cut into strips or slices, the maximum thickness of which does not exceed 6-8mm); the pretreated sweet potato Put it into the expansion tank body 2, open the direct steam valve 13 and the indirect steam heating valve 7 to feed saturated steam into the expansion tank body 2 and the heating shelf 3, and use the saturated steam to directly heat the sweet potatoes to the expansion temperature (121 ° C ~ 130°C), constant temperature for about 1 to 2 minutes; close the direct steam valve 13, open the vacuum valve 6, and puff the dried sweet potato. Subsequently, open the drain valve 12 and the pressure balance valve 15, let the steam condensed water in the expansion tank body 2 be discharged to the condensed water tank 10, after exhausting the steam condensed water in the expansion tank body 2, close the drain valve 12 and the pressure balan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com