Apparatus and method for desalinating sea sands

A sea sand and desalination system technology, applied in chemical instruments and methods, seawater treatment, water/sludge/sewage treatment, etc., can solve problems such as damage to reinforced concrete structures and corrosion, and achieve the effect of reducing the cost of sea sand desalination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

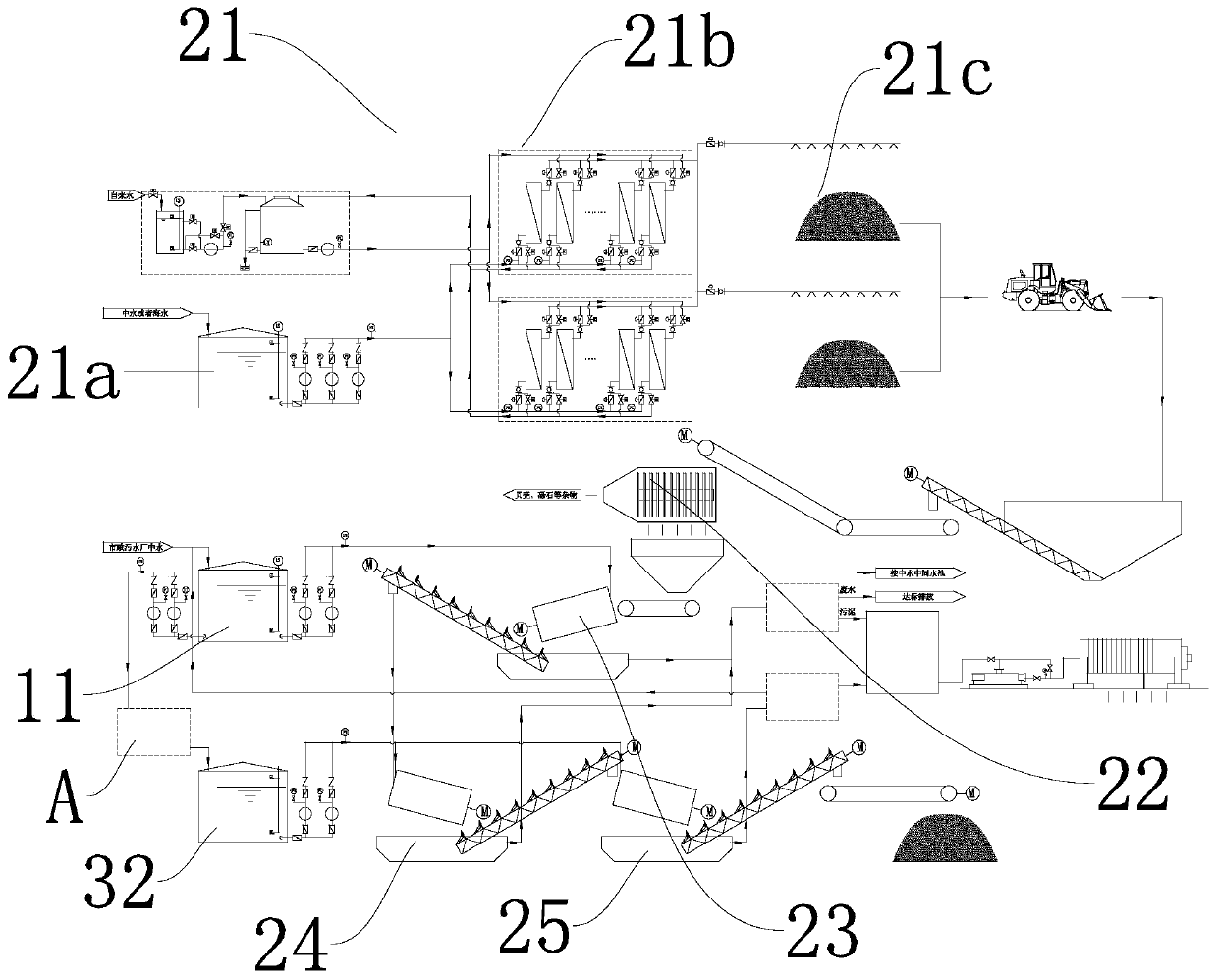

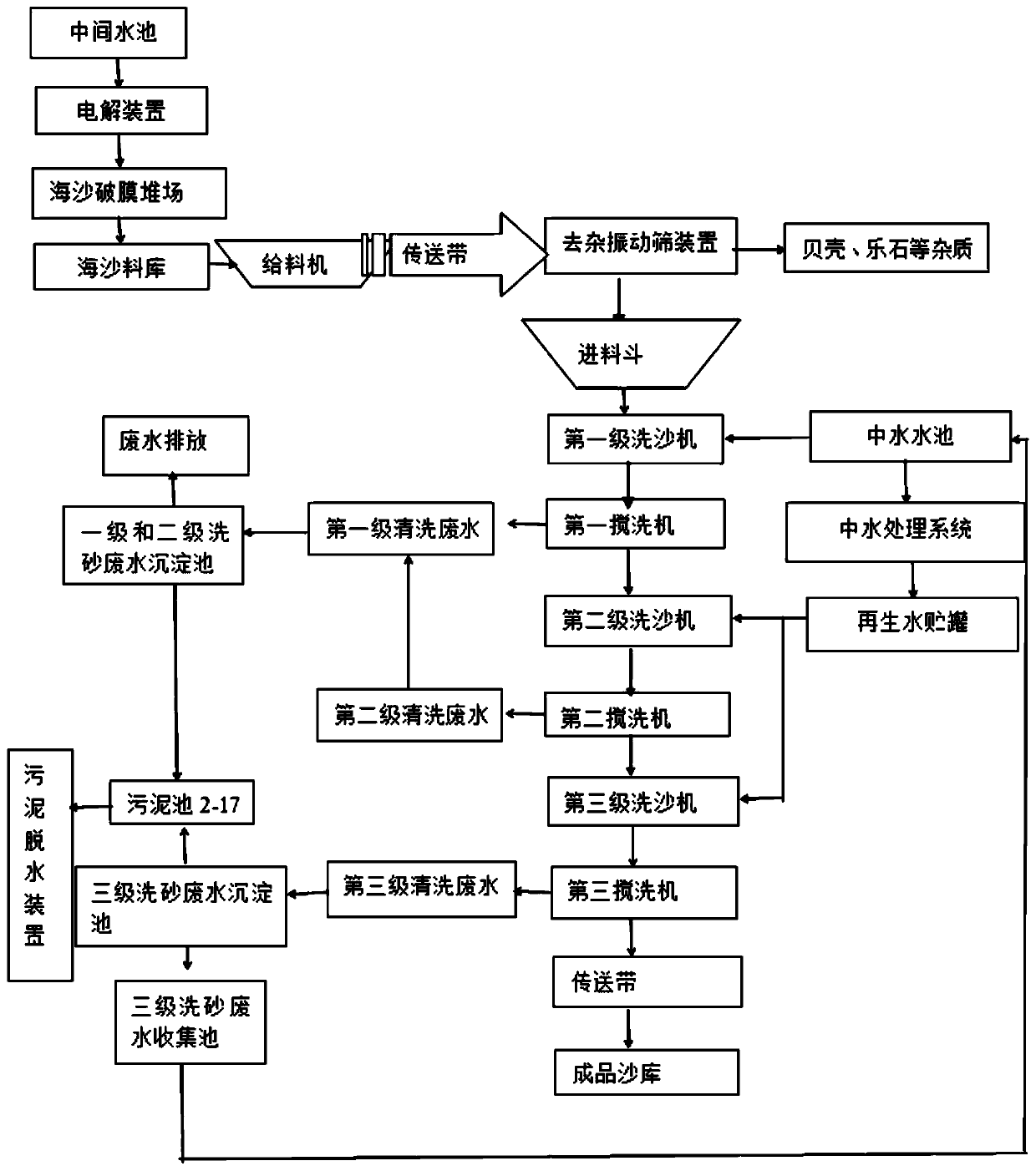

[0030] Reference manual attached figure 1 And attached image 3 , a sea sand desalination device, which is composed of an urban sewage plant reclaimed water manufacturing system and a sea sand desalination and desalination system:

[0031]The regenerated water production system is at least composed of a reclaimed water tank 11, a lift pump, a pre-filtration device and a reverse osmosis system 14, wherein the reclaimed water tank 11, a lift pump, a pre-filter device and a reverse osmosis system 14 (or an ion exchange desalination system) Connected in sequence, the water in the reclaimed water pool 11 is reclaimed water from the urban sewage treatment plant. The pre-filter device includes a first filter device 131 and a second filter device 132. The first filter device includes a multimedia filter a and an activated carbon filter b connected to the reclaimed water pool 11 in sequence, and removes silt, sand, and sand in the reclaimed water in advance. Suspended solids, colloid...

no. 2 example

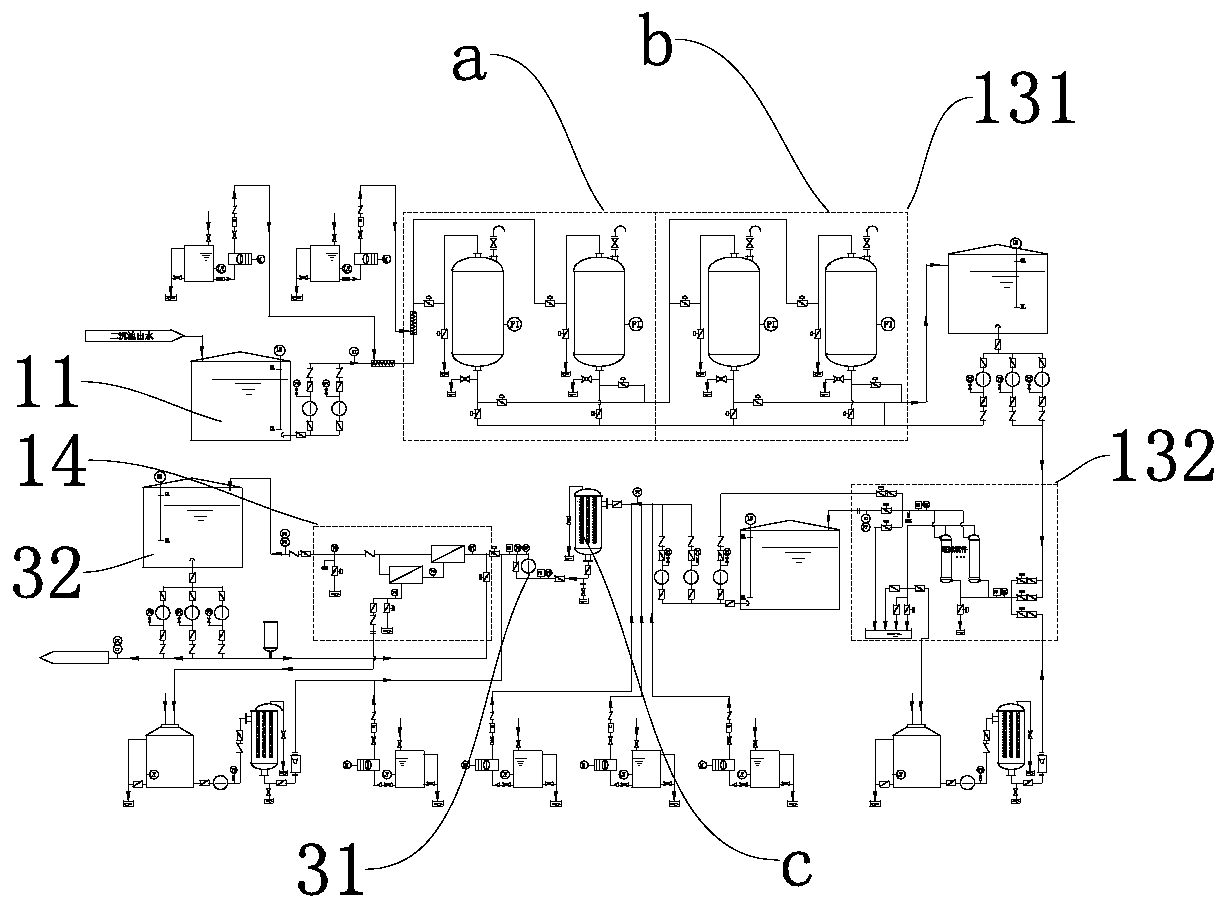

[0046] Reference manual attached Figure 4 , a sea sand desalination device using desalinated water as raw material, which consists of a sea water desalination system and a sea sand desalination system:

[0047] The seawater desalination system is at least composed of a seawater intake well 11', a lift pump, a seawater purification and disinfection device, a pre-filtration device and a seawater desalination device 14' (such as a reverse osmosis filtration device); a seawater intake well 11', a lift pump, and a seawater purification and disinfection device , the pre-filter device and the seawater desalination device 14' are sequentially connected. The pre-filter device 13 includes a first filter device 131' and a second filter device 132', the first filter device includes a multimedia filter a' and an activated carbon filter b' connected to the reclaimed water pool 11 in sequence, and pre-removes Silt, suspended solids, colloids and other impurities in the reclaimed water, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com