Method for preparing 2,6-diethyl-4-methyl bromobenzene

A technology of methyl bromide benzene and diethyl, applied in the field of preparation of pesticide intermediates, can solve the problems of long production time, low production efficiency, and large safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

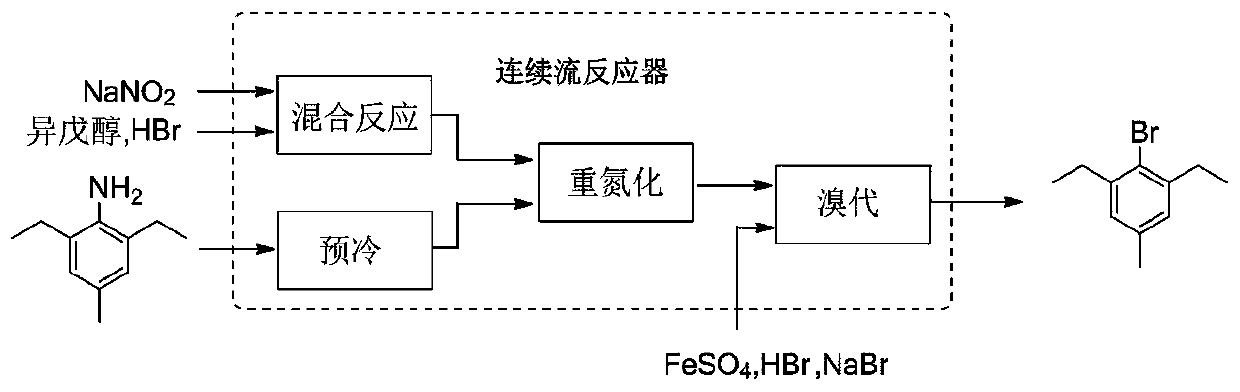

[0076] Preparations: if figure 1 Assemble the microchannel continuous flow reactor, mix ferrous sulfate heptahydrate, sodium bromide and hydrobromic acid in a molar ratio of 0.2:1.5:1.7 to obtain a uniformly mixed solution.

[0077] The operation of the microchannel continuous flow reactor: set the flow parameters of each pump and the temperature parameters of each temperature zone so that 2,6-diethyl-4-methylaniline, isoamyl alcohol, hydrobromic acid and 25wt% The mol ratio of sodium nitrite four is 1:1.5:1.65:1.8, and the mass flow rate of controlling isoamyl alcohol is 20g / min, and the mass flow rate 42g / min of hydrobromic acid, 25wt% sodium nitrite aqueous solution mass flow rate is 75g / min min, the reaction temperature of the first and second modules is 0°C, pump 2,6-diethyl-4-methylaniline, and control the mass flow rate to 24.7g / min, the reaction temperature of the third block is 5°C, The mass flow rate pumped into the mixed solution of ferrous sulfate heptahydrate, so...

Embodiment 2

[0085] Preparations: if figure 1 Assembled the microchannel continuous flow reactor, ferrous sulfate heptahydrate, sodium bromide and hydrobromic acid were prepared in a molar ratio of 0.2:2.0:2.0 (with 2,6-diethyl-4-methylaniline 1) to obtain a homogeneously mixed solution.

[0086] The operation of the microchannel continuous flow reactor: set the flow parameters of each pump and the temperature parameters of each temperature zone so that 2,6-diethyl-4-methylaniline, isoamyl alcohol, hydrobromic acid and 25wt% The mol ratio of sodium nitrite four is 1:1.5:1.8:1.8, and the mass flow of controlling isoamyl alcohol is 30g / min, and the mass flow of hydrobromic acid 68.8g / min, 25wt% sodium nitrite aqueous solution mass flow is 112.7 g / min, the reaction temperature of the first and second modules is 0°C, pump 2,6-diethyl-4-methylaniline, control the mass flow rate to 37g / min, and the reaction temperature of the third block is 5°C , the mass flow rate pumped into the mixed soluti...

Embodiment 3

[0094] Preparations: if figure 1 Assemble the microchannel continuous flow reactor, mix ferrous sulfate heptahydrate, sodium bromide and hydrobromic acid in a molar ratio of 0.2:2.0:2.0 to obtain a uniformly mixed solution.

[0095] The operation of the microchannel continuous flow reactor: set the flow parameters of each pump and the temperature parameters of each temperature zone so that 2,6-diethyl-4-methylaniline, isoamyl alcohol, hydrobromic acid and 25wt% The mol ratio of sodium nitrite four is 1:2.5:3.75:3.75, and the mass flow of controlling isoamyl alcohol is 30g / min, and the mass flow of hydrobromic acid 86g / min, 25wt% sodium nitrite aqueous solution mass flow is 140.8g / min, the reaction temperature of the first and second modules is 5°C, pump 2,6-diethyl-4-methylaniline, control the mass flow rate to 22.2g / min, and the reaction temperature of the third block is 5°C , the mass flow rate pumped into the mixed solution of ferrous sulfate heptahydrate, sodium bromide an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com