An acrylic emulsion adhesive for bonding low surface energy substrates and its preparation method

An acrylate and low surface energy technology, applied in adhesive types, ester copolymer adhesives, etc., can solve problems such as long curing time, low initial adhesion, and reduced production efficiency, and achieve good sticking effect, The effect of high peel strength and high initial adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

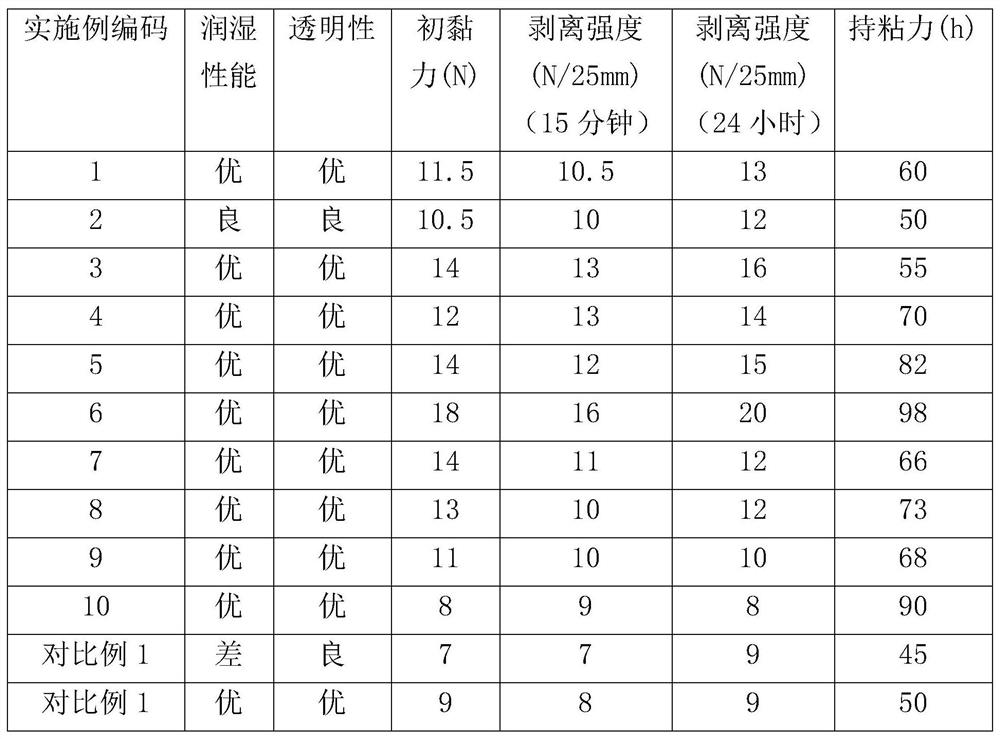

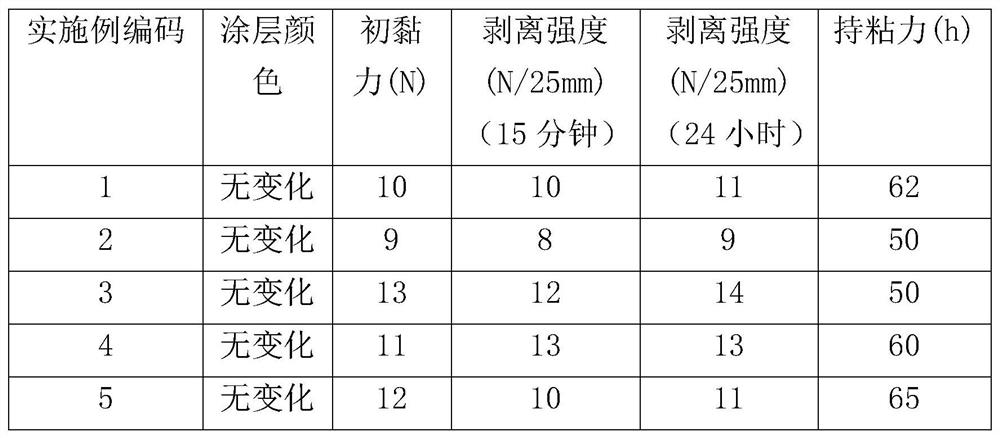

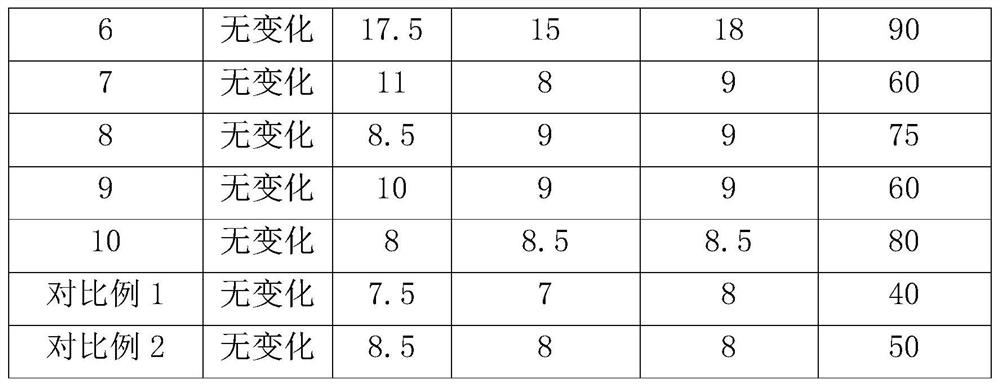

Examples

Embodiment 1

[0058] Add 130g of water, 15g of seed emulsion and 0.5g of sodium dodecylbenzenesulfonate to the 1000ml four-neck flask equipped with an electric stirrer, condenser tube and thermometer, raise the temperature to 88°C, and add 0.2g Water-soluble initiator, start dripping oily phase and remaining 2g water-soluble initiator after 5 minutes, oily phase is by 100g deionized water, 2g anionic emulsifier, 10g methyl methacrylate, 20g styrene, 80g butyl acrylate, 300g of isooctyl acrylate and 5g of methacrylic acid MAA are added dropwise at a rate of 50% for the first half an hour, and then added dropwise at full speed. The whole dropping process lasts for 5 hours and the temperature is kept at 86-88°C. After the dropwise addition, keep warm for 1 hour, cool down to 75 degrees, use 1g of tert-butyl peroxide and 0.8g of white powder for post-treatment, after 1 hour of addition, cool down to below 40 degrees, add 50g of rosin emulsion Snowtack780, stir evenly, Adjust the pH to 7-8, filt...

Embodiment 2

[0060]Add 130g of water, 5g of seed emulsion and 0.5g of sodium dodecylbenzene sulfonate to the 1000ml four-necked flask equipped with electric stirrer, condenser and thermometer directly, raise the temperature to 88°C, and add 0.2g Water-soluble initiator, start dripping oily phase and remaining 2g water-soluble initiator after 5 minutes, oily phase is by 100g deionized water, 2g anionic emulsifier, 10g methyl methacrylate, 20g styrene, 80g butyl acrylate, 300g of isooctyl acrylate and 5g of methacrylic acid MAA are added dropwise at a rate of 50% for the first half an hour, and then added dropwise at full speed. The whole dropping process lasts for 5 hours and the temperature is kept at 86-88°C. After the dropwise addition, keep warm for 1 hour, lower the temperature to 75 degrees, use 1g of tert-butyl peroxide and 0.8g of white block for post-treatment, after 1 hour of addition, cool down to below 40 degrees, add 50g of rosin emulsion Snowtack 780, and stir evenly , adjust ...

Embodiment 3

[0062] Add 130g of water, 15g of seed emulsion and 1g of sodium dodecylbenzene sulfonate directly into a 1000ml four-necked flask equipped with an electric stirrer, condenser and thermometer, raise the temperature to 88°C, and add 0.2g of water-soluble After 5 minutes, start dripping oily phase and remaining 2g water-soluble initiator, oily phase is by 100g deionized water, 2g anionic emulsifier, 10g methyl methacrylate, 20g styrene, 80g butyl acrylate, 300g Isooctyl acrylate and 5g of methacrylic acid MAA are added dropwise at a rate of 50% for the first half hour, and then added dropwise at full speed. The whole drop process lasts for 5 hours, and the temperature is kept at 86-88°C. After the dropwise addition, keep warm for 1 hour, cool down to 75 degrees, use 1g of tert-butyl peroxide and 0.8g of white powder for post-treatment, after 1 hour of addition, cool down to below 40 degrees, add 100g of rosin emulsion Snowtack780, stir evenly, Adjust the pH to 7-8, filter and dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com