Nano-titanium oxide anti-wear additive and method for preparing nano-titanium oxide

A nano-titanium oxide and additive technology, applied in the field of nano-materials, can solve the problems of increased mechanical resistance, metal surface wear, secondary wear and scratches, etc., to improve PB value, protect metal surface wear, and prolong life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

[0025] The nano-titanium oxide anti-wear additive comprises: 93% of base oil; 3% of nano-titanium oxide; and 4% of pentaerythritol ester.

[0026] Wherein, the preparation method of nano-titanium oxide is:

[0027] Weigh 14.8g of titanium nitrate, 60g of pure water, and 3.75g of glycine, of which 0.05mol of titanium nitrate, 0.05mol of glycine, and a concentration of 4.44g / mol of titanium nitrate solution are put into a magnet and heated and stirred at 120°C 24h, until the water in the solution is completely evaporated and the gel appears. Put the sample on the heating plate in the fume hood at a temperature of 300-320°C. When the water reaches the critical point of complete drying, the gel solution will undergo a combustion reaction. , In a very short time, the instantaneous combustion reaction synthesizes nano-titanium oxide. Wherein, the particle size of the nano-titanium oxide is 100-200nm.

Embodiment example 2

[0029] The nanometer titanium oxide anti-wear additive, calculated by weight percentage, includes: 97% of base oil; 1% of nanometer titanium oxide; and 2% of sulfurized isobutylene.

[0030] Wherein, the preparation method of nano-titanium oxide is:

[0031] Weigh 17.76g of titanium nitrate, 60g of pure water, and 4.5g of glycine, of which 0.06mol of titanium nitrate, 0.06mol of glycine, and a concentration of 5.33g / mol of titanium nitrate solution are put into a magnet and heated and stirred at 130°C 20h, until the water in the solution is completely evaporated and the gel appears, put the sample on a heating plate in a fume hood at a temperature of 300-320°C, when the water reaches the critical point of complete drying, the gel solution will undergo a combustion reaction , In a very short time, the instantaneous combustion reaction synthesizes nano-titanium oxide. Wherein, the particle size of the nano-titanium oxide is 100-200nm.

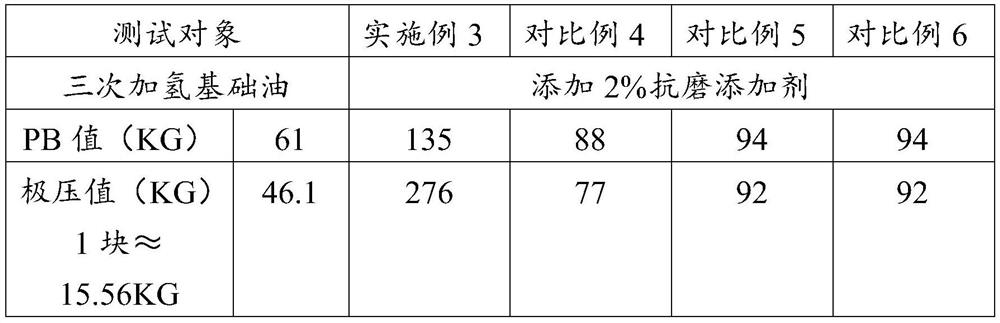

Embodiment example 3

[0033] The anti-wear additive of nano titanium oxide, calculated by weight percentage, includes: 95% of base oil; 2% of nano titanium oxide; and 3% of sulfurized calcium alkylphenate.

[0034] Wherein, the preparation method of nano-titanium oxide is:

[0035] Weigh 23.7g of titanium nitrate, 60g of pure water, and 6g of aminoacetic acid, of which 0.08mol of titanium nitrate, 0.08mol of aminoacetic acid, and a concentration of 7.11g / mol of the titanium nitrate solution are placed in a magnet and heated and stirred at 100°C for 28h , until the water in the solution evaporates completely and becomes gelatinous. Put the sample on a heating plate in a fume hood at a temperature of 300-320°C. When the water reaches the critical point of complete drying, the gelatinous solution undergoes a combustion reaction. In a very short time, the instant combustion reaction synthesizes nano-titanium oxide. Wherein, the particle size of the nano-titanium oxide is 100-200nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com