Alkali reducing method of textiles containing CDP fiber

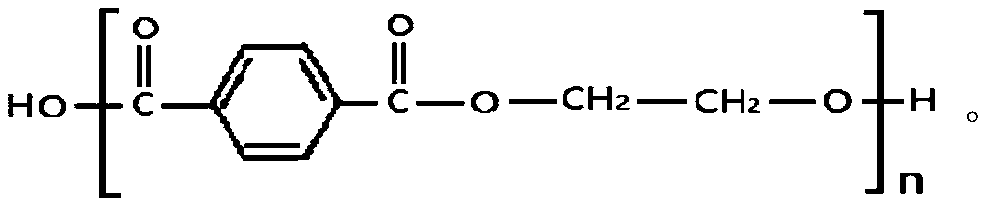

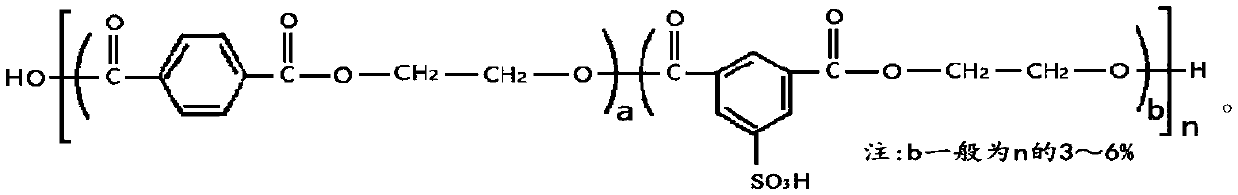

An alkali reduction and textile technology, applied in textiles and papermaking, fiber processing, fiber types, etc., can solve the problems of CDP fiber strength reduction, affecting the dyeing of cationic dyes, etc., and achieve the effect of soft luster, ample time and soft hand feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Embodiment 1: a kind of alkali reduction method of the textile containing CDP fiber, comprises the steps:

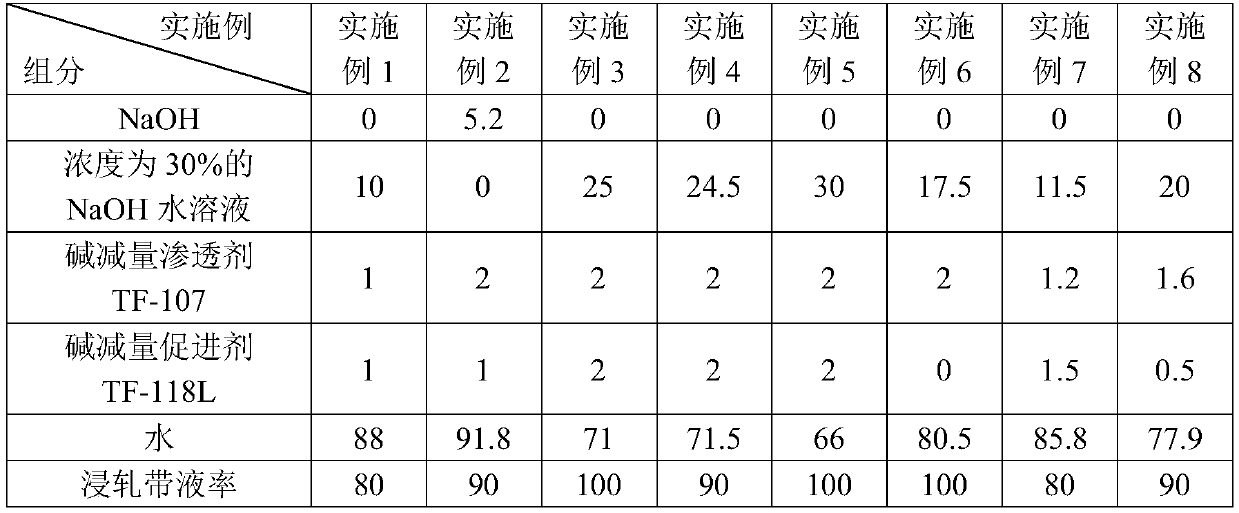

[0053] Step 1, according to the amount in Table 1, each component is formed to cooperate with each other to make a padding liquid;

[0054] Step 2, immerse the fabric containing CDP fiber in the padding liquid, roll the fabric containing CDP fiber with a liquid rate of 80% to form a cloth roll, and wrap the plastic film on the outside of the cloth roll, and wrap the cloth roll with The rotation speed in Table 2 rotates around the axis of the cloth roll, and the corresponding time is piled up at the temperature disclosed in Table 2;

[0055] Step 3, remove the plastic film, take out and unwind the stacked cloth rolls, and wash them on the open-width continuous washing machine. The temperature set in the first tank and the second tank, the temperature set in the third tank and the fourth tank , the fifth tank and the sixth tank, the temperature set in the seventh t...

Embodiment 2-8

[0056] Embodiment 2-8: A method for alkali weight reduction of textiles containing CDP fibers. The difference from Example 1 is that the components included in the padding solution and their corresponding weight percentages, and the padding liquid rate , Alkali reduction rate, and alkali utilization rate are shown in Table 1.

[0057] Components included in table 1 embodiment 1-8 padding liquid and their corresponding weight percentages and padding liquid rate, alkali reduction rate, alkali utilization rate (%)

[0058]

[0059] Rotating speed, stacking temperature and time of cloth winding axis line in table 2 embodiment 1-8

[0060]

[0061] The temperature (℃) set by each tank on the open-width continuous washing machine in Table 3 embodiment 1-8

[0062]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com