Voltage-stabilizing printing-down machine

A technology of plate pressing machine and zener diode, which is applied to exposure devices, printing devices, instruments and other directions of photoplate making process, can solve the problems of loss, affecting the service life of lamps, and high power, and achieves enhanced safety, protection and resistance. Radiant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

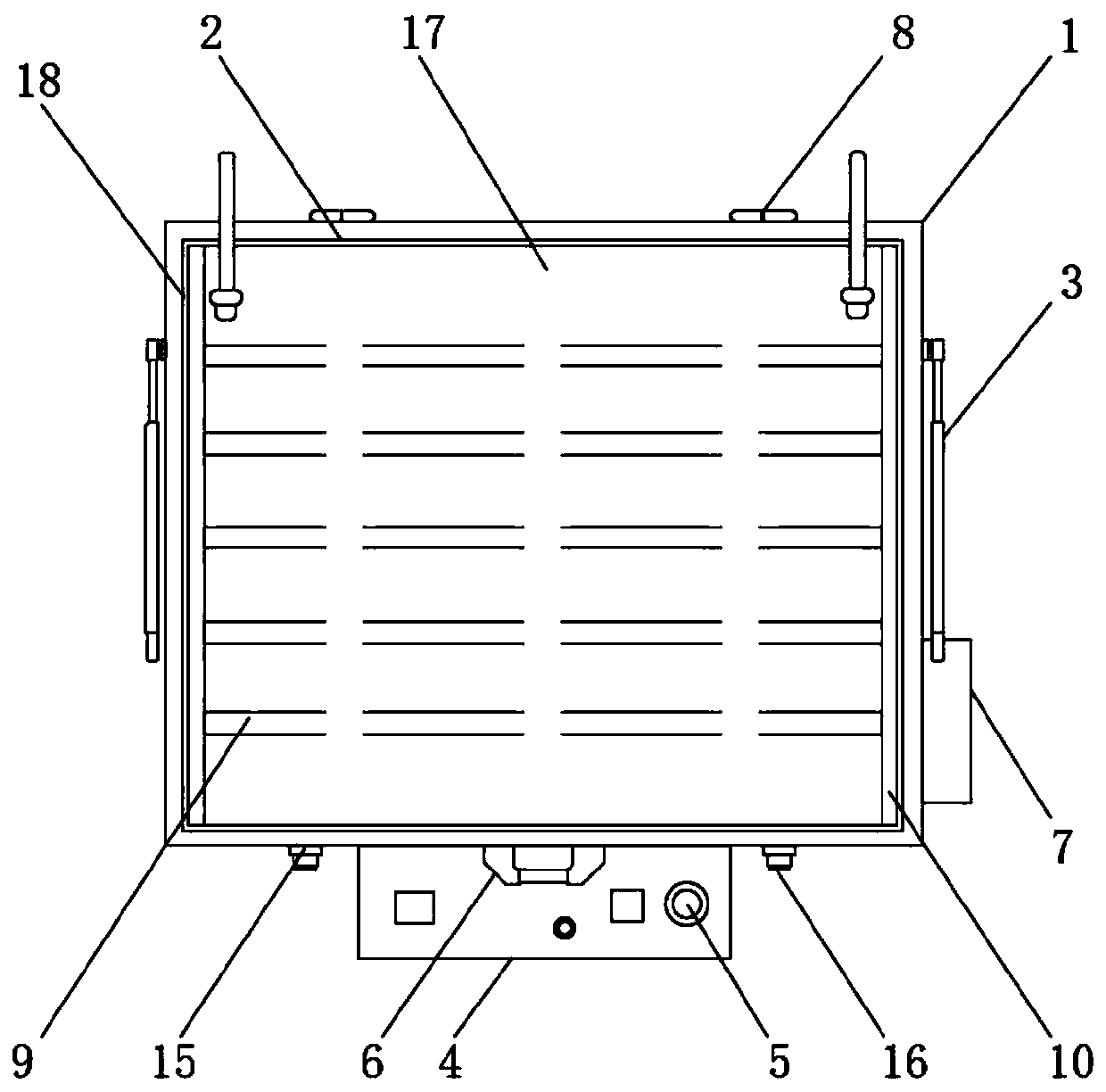

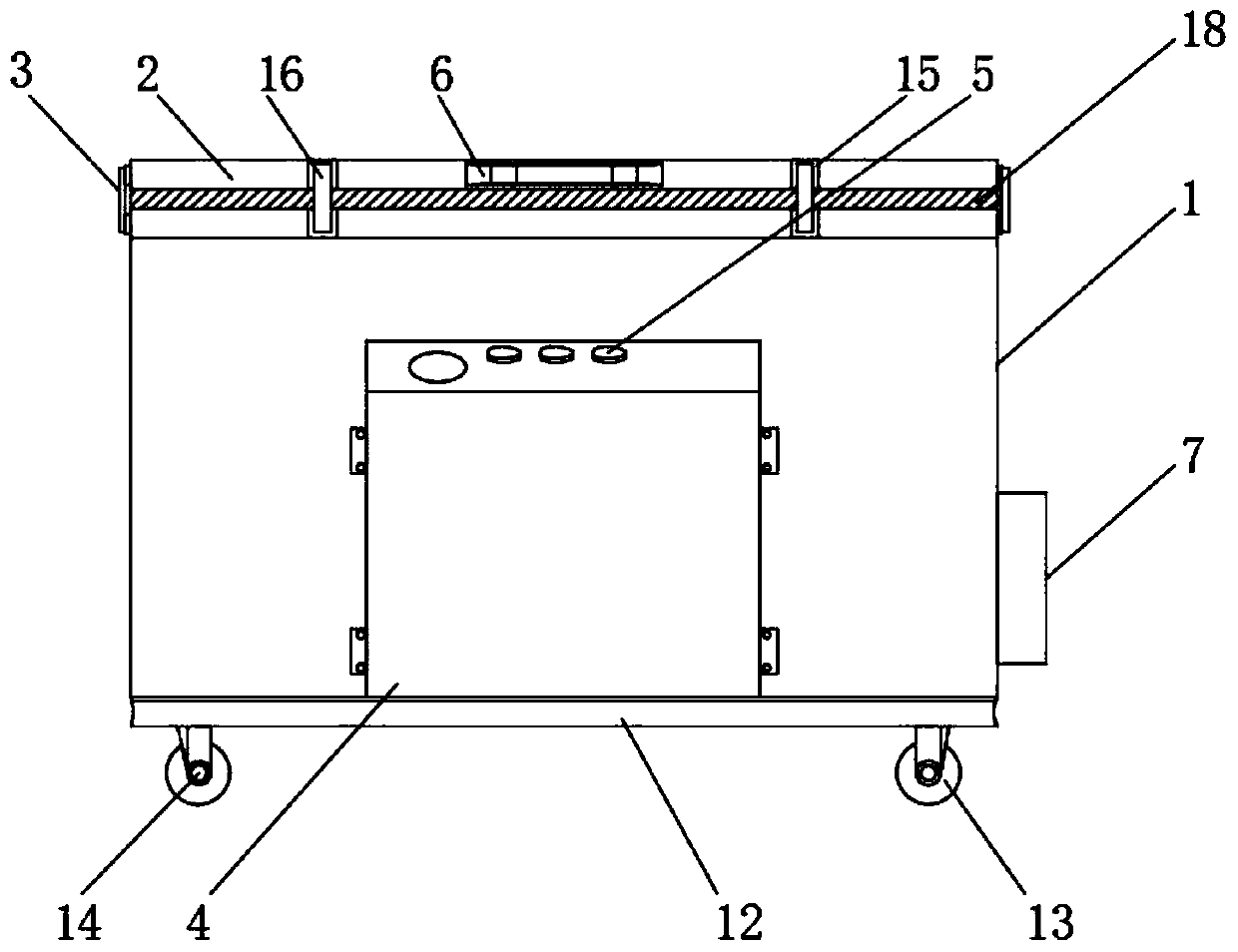

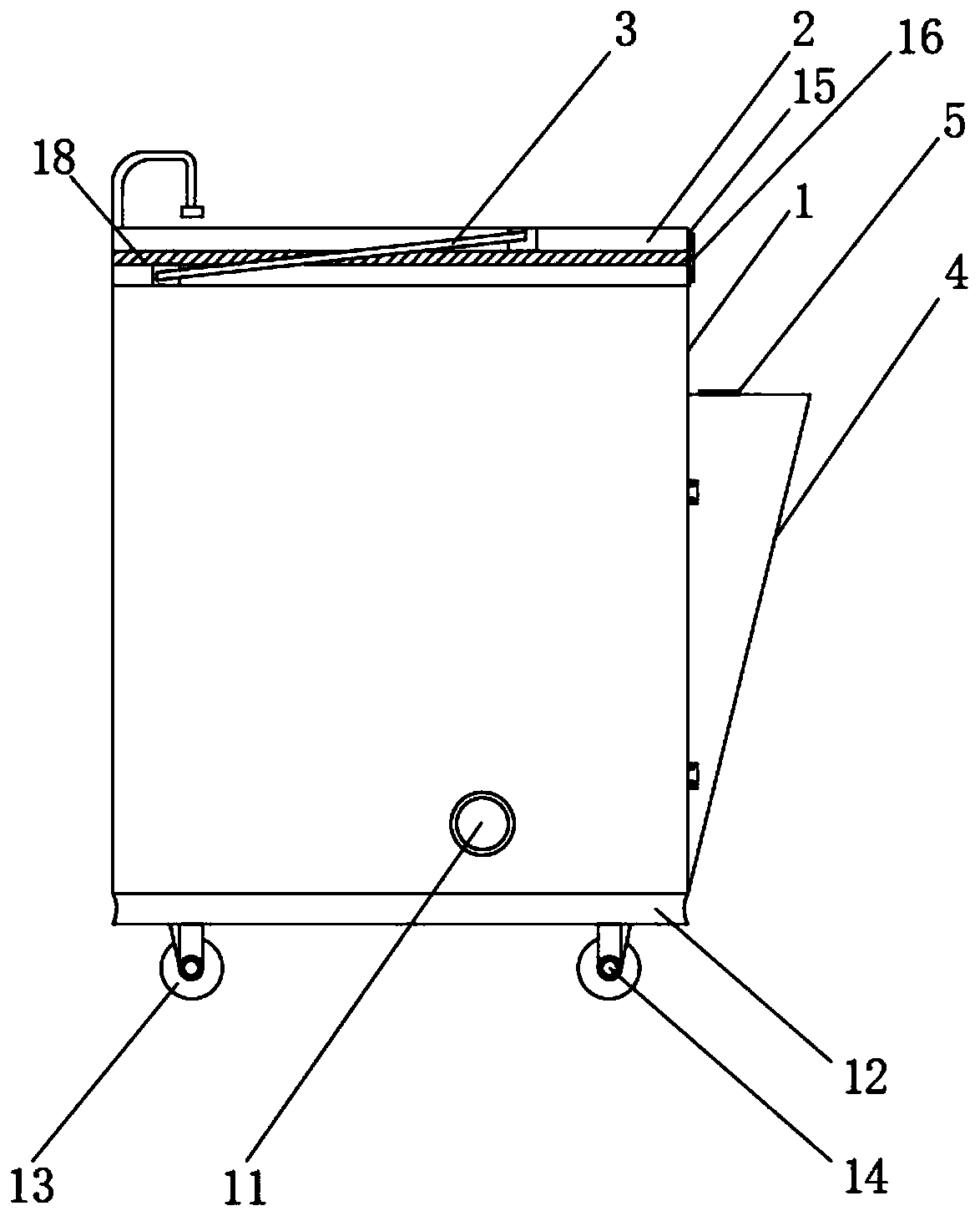

[0023] like Figure 1-3 As shown, the present invention provides a voltage-stabilizing printing machine, which includes a body 1, a cover plate 2 is installed on the top of the body 1, telescopic rods 3 are arranged on both sides of the cover plate 2 and the body 1, and the front end of the body 1 is provided with There is an operation table 4, the top of the operation table 4 is provided with a control panel 5, one end of the cover plate 2 is provided with a handle 6, and the handle 6 is located on the top of the operation table 4, one side of the body 1 is provided with a vacuum pump 7, and the rear of the body 1 A connecting block 8 is arranged on the end face, and several lamp tubes 9 are arranged inside the body 1, Zener diodes 10 are connected to both ends of the several lamp tubes 9, an air vent 11 is arranged on the other side of the body 1, and a vent 11 is arranged on the bottom of the body 1. There is a base 12 , a vacuum chamber 17 is arranged inside the body 1 , a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com