Positive lead paste for lead-acid storage batteries and preparation method and application thereof

A lead-acid battery, positive lead paste technology, applied in lead-acid batteries, battery electrodes, batteries, etc., to achieve the effect of stabilizing the concentration of crystal glue, reducing resistance, and enhancing the ability to conduct current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

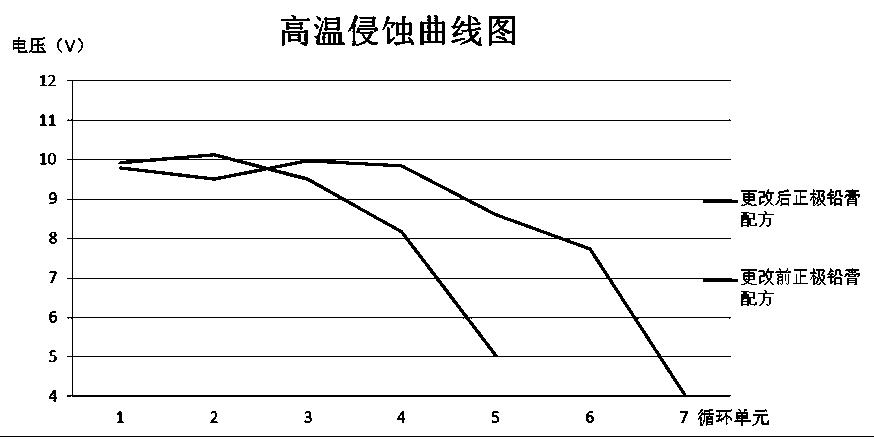

Problems solved by technology

Method used

Image

Examples

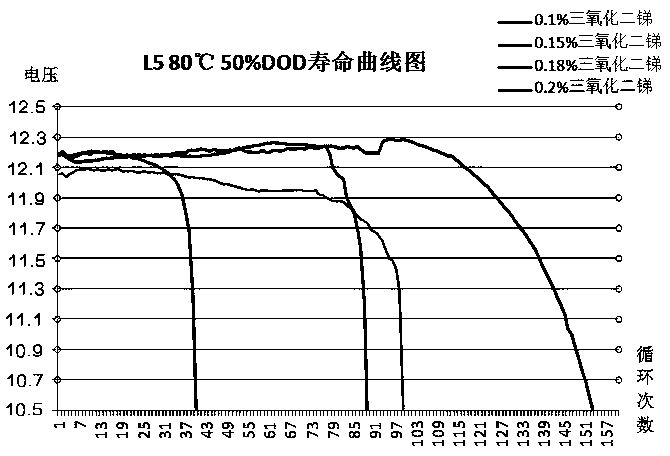

Embodiment 1

[0031]A kind of lead-acid accumulator positive pole lead paste, is made up of each material of following mass percentage: Lead powder 73%, 50wt.% sulfuric acid solution 10.45%, deionized water 11%, red lead 5%, sodium perborate 0.3%, trioxide Antimony 0.15%, graphite powder 0.02%, fiber 0.08%.

Embodiment 2

[0033] A kind of lead-acid accumulator positive pole lead paste, is made up of each material of following mass percentage: Lead powder 76.56%, 49wt.% sulfuric acid solution 9%, deionized water 10%, red lead 4%, sodium perborate 0.1%, trioxide Antimony 0.12%, graphite powder 0.15%, fiber 0.07%.

Embodiment 3

[0035] A positive lead paste for a lead-acid storage battery, consisting of the following substances in mass percent: 73.58% of lead powder, 11% of 50wt.% sulfuric acid solution, 12% of deionized water, 3% of red lead, 0.2% of sodium perborate, trioxide Diantimony 0.10%, graphite powder 0.05%, fiber 0.07%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com