Capacitor battery and preparation method thereof

A capacitor battery and electrode slurry technology, which is applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, non-aqueous electrolyte battery electrodes, etc. The density is uniform and the effect of volume change is satisfied

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

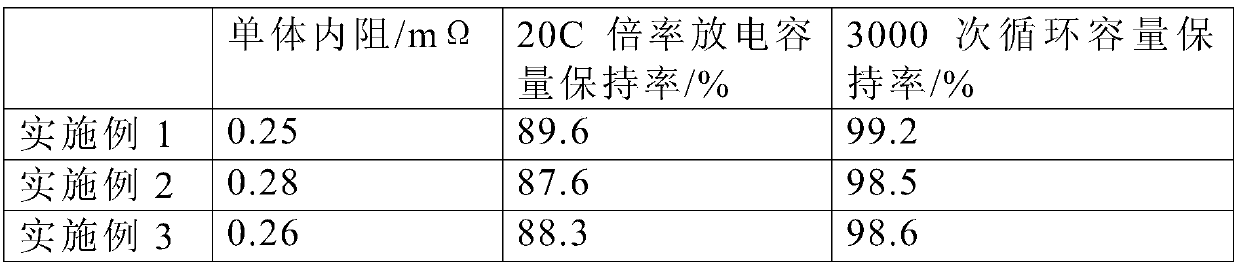

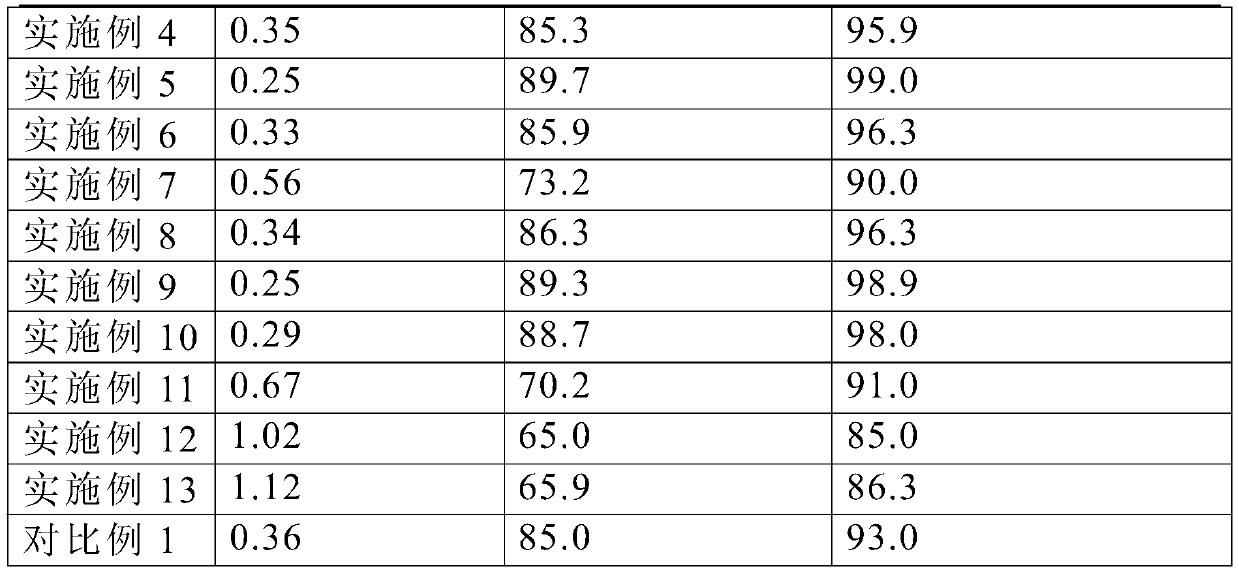

Examples

Embodiment 1

[0038] The positive porous carbon electrode slurry is made of carbon airgel, PTFE and carbon nanotubes in a ratio of 90:5:5, and the positive electrode lithium metal salt electrode slurry is made of lithium manganate, PVDF, and carbon black in a ratio of 89: 5:6 mixed, the negative electrode disordered carbon electrode slurry is made of carbon airgel, PTFE and carbon nanotubes in a ratio of 90:5:5, the negative electrode graphite slurry is made of graphite, SBR / CMC, graphite The ratio of ethylene is 90:6:4;

[0039] The positive electrode porous carbon electrode slurry and the metal lithium salt electrode slurry are coated on the aluminum foil in sequence. The thickness of the single-side coating of the porous carbon electrode slurry is 15 μm, and the thickness of the single-side coating of the metal lithium salt electrode slurry is 105 μm;

[0040] The negative electrode disordered carbon electrode slurry and graphite slurry are coated on the copper foil in sequence, the thic...

Embodiment 2

[0043] The positive porous carbon electrode slurry is made of activated carbon, SBR / CMC and Ketjen carbon in a ratio of 90:5:5, and the positive electrode lithium metal salt electrode slurry is made of lithium iron phosphate, SBR / CMC, and carbon black in a ratio of 88 :6:6 mixed, the negative electrode disordered carbon electrode slurry is made of activated carbon, SBR / CMC and Ketjen carbon in a ratio of 90:5:5, the negative electrode graphite slurry is made of hard carbon, SBR / CMC, The VCGF ratio is 90:5:5;

[0044] The positive porous carbon electrode slurry and the metal lithium salt electrode slurry are coated on the aluminum foil in sequence. The thickness of the single-side coating of the porous carbon electrode slurry is 17 μm, and the thickness of the single-side coating of the metal lithium salt electrode slurry is 103 μm;

[0045]The negative disordered carbon electrode slurry and the graphite slurry are coated on the copper foil in sequence, the thickness of the sin...

Embodiment 3

[0048] The positive porous carbon electrode slurry is made of mesoporous carbon, PTFE and carbon black in a ratio of 90:5:5, and the positive metal lithium salt electrode slurry is made of LiMnPO 4 , PVDF, and carbon black in a ratio of 89:5:6, the negative electrode disordered carbon electrode slurry is made of mesoporous carbon, PTFE, and carbon black in a ratio of 90:5:5, and the negative electrode graphite slurry is made of Soft carbon, SBR / CMC, and graphene are mixed at a ratio of 90:6:4;

[0049] The positive porous carbon electrode slurry and the metal lithium salt electrode slurry are coated on the aluminum foil in sequence, the thickness of the single-side coating of the porous carbon electrode slurry is 20 μm, and the thickness of the single-side coating of the metal lithium salt electrode slurry is 100 μm;

[0050] The negative electrode disordered carbon electrode slurry and graphite slurry are coated on the copper foil in sequence, the thickness of the single-side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com