A bus voltage fluctuation compensation method for vector control of permanent magnet synchronous motor without electrolytic capacitor

A permanent magnet synchronous motor, bus voltage technology, applied in the direction of motor generator control, electronic commutation motor control, motor control, etc., can solve the problems of low precision, complex control, large calculation amount, etc., and achieve small calculation amount , Wide range of applications, and the effect of reducing system costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

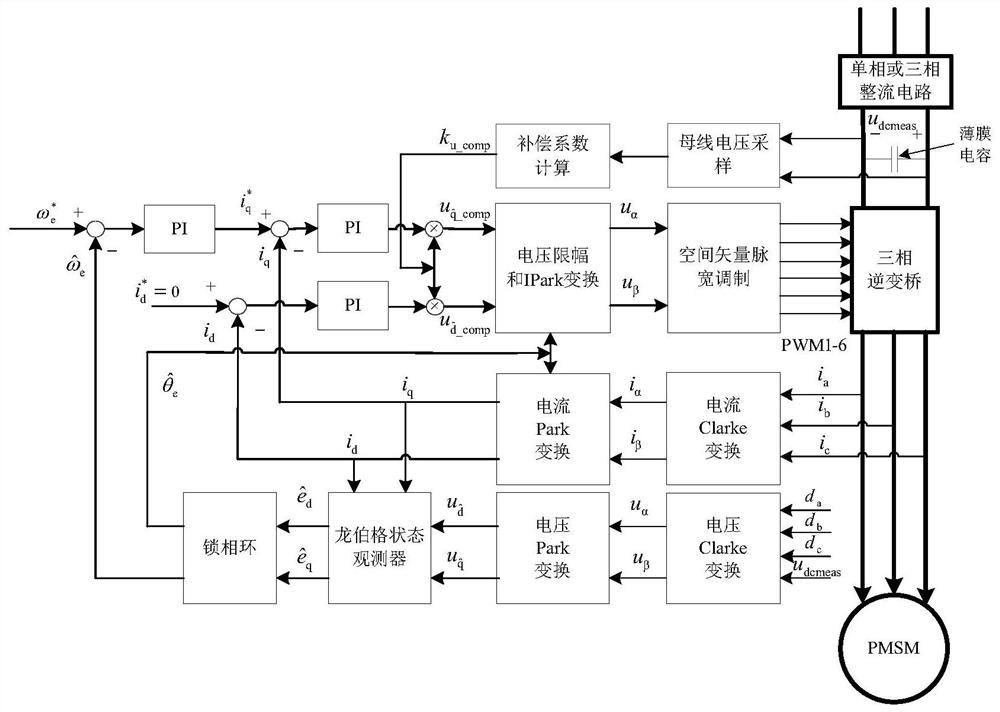

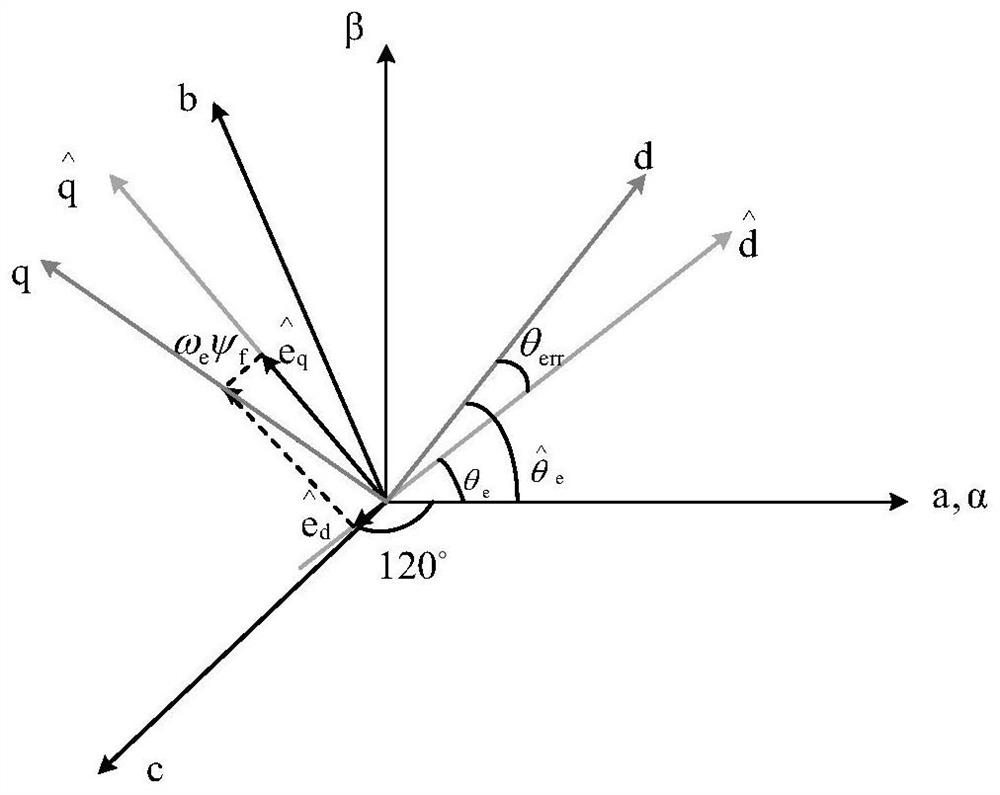

[0032] refer to figure 1 , a position sensorless control voltage compensation method for a permanent magnet synchronous motor without an electrolytic capacitor, which can achieve better steady-state performance when the permanent magnet synchronous motor driver has no busbar electrolytic capacitor, comprising the following steps:

[0033] Step 1. Detect the bus voltage, and calculate the voltage compensation coefficient k according to the real-time detected bus voltage and its changing law u_comp ,

[0034]

[0035] In the formula, U dcreal is the ideal bus voltage, U dcmeas is the bus voltage detected in real time;

[0036] Step 2, calculate the output phase voltage by detecting the bus voltage and the three-phase duty cycle,

[0037]

[0038] In the formula, d a 、d b 、d c are the three-phase duty cycle;

[0039] Then project the three-phase voltage ont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com