Plant seed dry powder coating method

A technology for plant seeds and coating, applied in the direction of seed coating/seed dressing, etc., can solve the problems of uneven seed coating, time-consuming power consumption, etc., to reduce curing time, save power resources, and use environmentally friendly pesticides. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Embodiment 1 single-layer seed coating

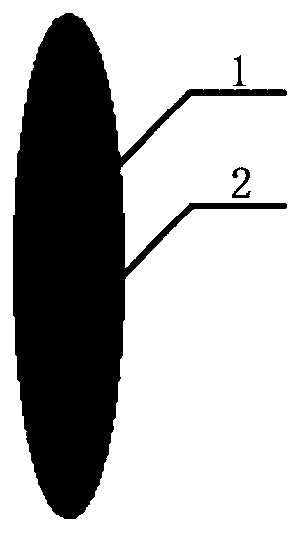

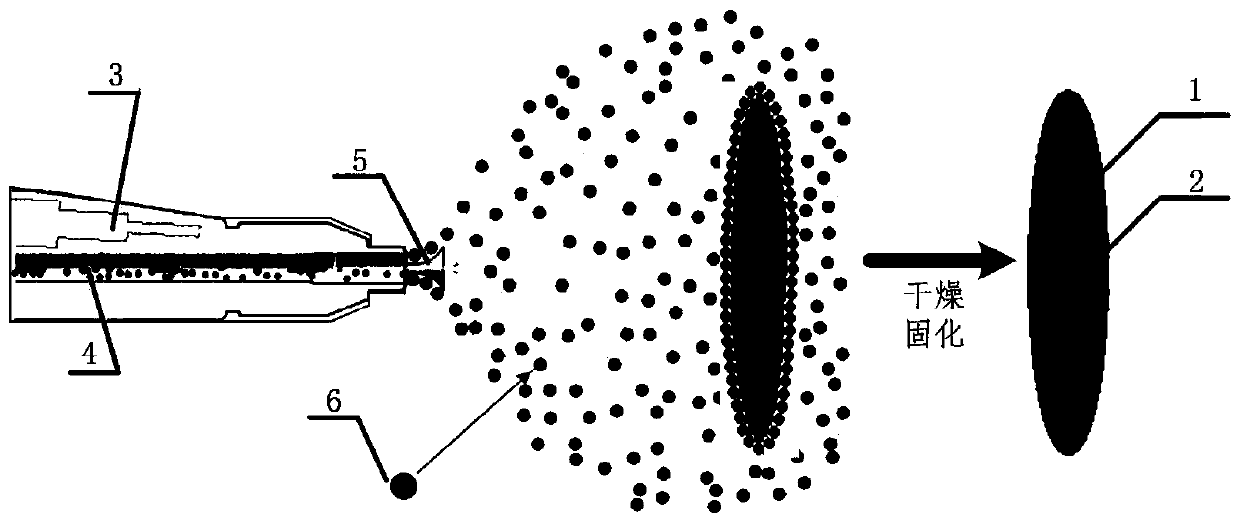

[0058] figure 1 For the plant seeds with a single coating layer prepared by using electrostatic dry powder coating technology in this example 1, including plant seeds 1 and coating layer 2, the preparation method is as follows:

[0059] (a) Prepare the plant seeds to be coated

[0060] The plant seeds to be coated need to be pretreated before coating, such as: cleaning, eliminating grains, small grains, broken grains, seeds with diseases and insect pests and various sundries; use sun exposure to promote the activity of enzymes inside the seeds , Reduce the content of germination-inhibiting substances in the seeds, increase the germination rate and play a role in sterilization; use water or drugs to soak the seeds, thereby promoting seed germination and eliminating pathogens, etc.; to obtain clean plant seeds that meet the coating requirements.

[0061] (b) Place the seeds to be coated in the coating machine

[0062] Place the ...

Embodiment 2

[0070] Embodiment 2 multi-layer seed coating

[0071] Its preparation method of the plant seed with multi-layer medicine coating layer is as follows:

[0072] (a) Prepare the plant seeds to be coated

[0073] The plant seeds to be coated need to be pretreated before coating, such as: cleaning, eliminating grains, small grains, broken grains, seeds with diseases and insect pests and various sundries; using sunlight exposure can promote the enzymes in the seeds. Activity, reducing the content of germination-inhibiting substances in seeds, increasing germination rate and sterilizing effects; soaking seeds with water or drugs to promote seed germination and eliminate pathogens, etc.; to obtain clean plant seeds that meet the coating requirements.

[0074] (b) Place the seeds to be coated in the coating machine

[0075] Place the plant seeds in the grounded coating machine and turn on the coating machine. Using the heating function of the mechanical device to heat the seeds, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com