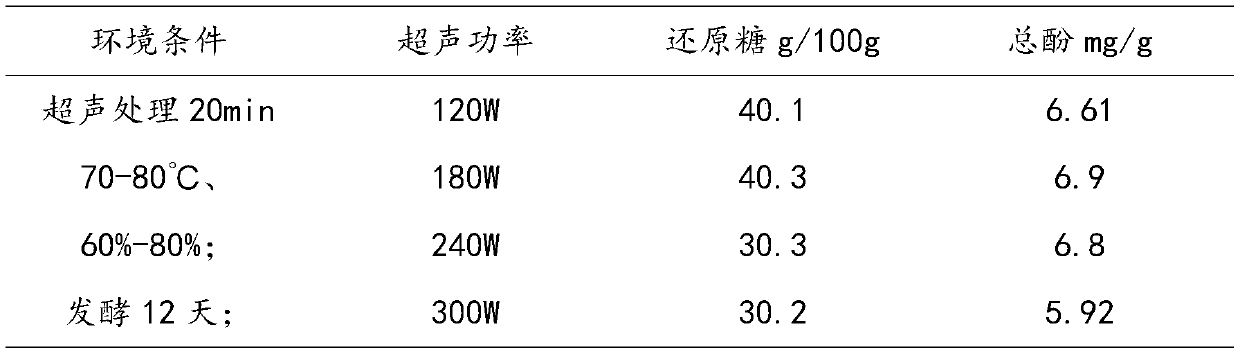

Process for preparing black garlic by ultrasonic pretreatment

An ultrasonic and pretreatment technology, applied in the field of ultrasonic pretreatment to prepare black garlic, can solve the problems of difficult control of product quality and long fermentation time, and achieve the effects of reducing fermentation time, simple operation and easy to master.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A process for preparing black garlic includes the following steps:

[0028] Single-head garlic treatment: select fresh, full and undamaged single-head garlic, remove the outer skin and only retain the innermost layer;

[0029] High-temperature and high-humidity fermentation: Place the treated single-head garlic in a black garlic fermentation pot and ferment for 6 days at 70-80°C and 60%-80%; power failure should not exceed 5 hours.

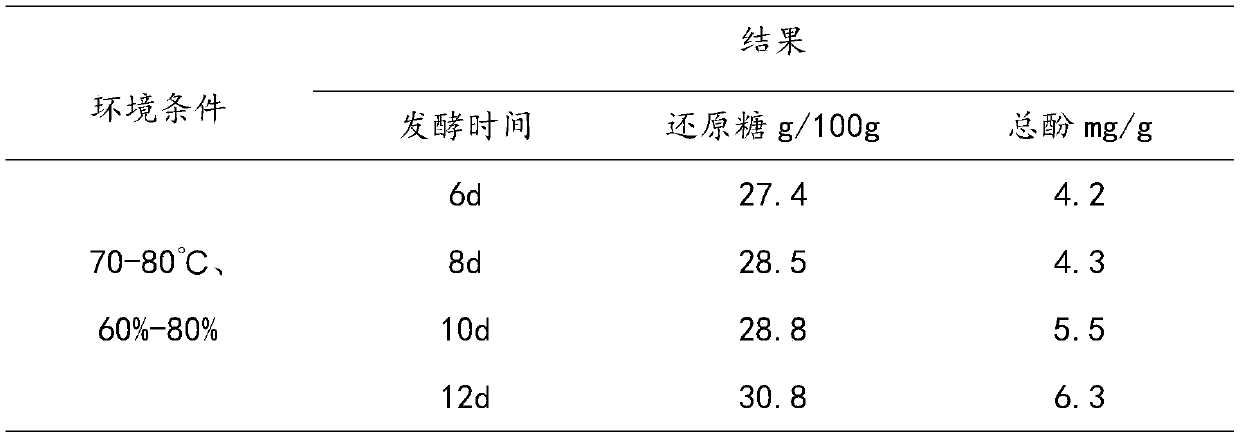

[0030] The beneficial effects of this embodiment are: fermenting at 70-80°C and 60%-80% for 6 days, the reducing sugar content in black garlic measured by the GB / T5009.7-2008 method is 27.4g / 100g; The total phenol content in black garlic measured by the standard curve method is 4.2 mg / g.

Embodiment 2

[0032] A process for preparing black garlic includes the following steps:

[0033] Single-head garlic treatment: select fresh, full and undamaged single-head garlic, remove the outer skin and only retain the innermost layer;

[0034] High-temperature and high-humidity fermentation: Put the treated single-head garlic in a black garlic fermentation pot and ferment for 8 days at 70-80°C and 60%-80%; power failure should not exceed 5 hours.

[0035] The beneficial effects of this embodiment are: fermenting for 8 days under the conditions of 70-80°C and 60%-80%, and the reducing sugar content in black garlic measured by the GB / T5009.7-2008 method is 28.5g / 100g; The total phenol content in black garlic measured by the standard curve method is 4.3 mg / g.

Embodiment 3

[0037] A process for preparing black garlic includes the following steps:

[0038] Single-head garlic treatment: select fresh, full and undamaged single-head garlic, remove the outer skin and only retain the innermost layer;

[0039] High-temperature and high-humidity fermentation: Put the treated single-head garlic in a black garlic fermentation pot and ferment for 10 days at 70-80°C and 60%-80%; power failure should not exceed 5 hours.

[0040] The beneficial effects of this embodiment are: fermented for 10 days at 70-80°C and 60%-80%, and the reducing sugar content in black garlic measured by the GB / T5009.7-2008 method is 28.8g / 100g; The total phenol content in black garlic measured by the standard curve method is 5.5 mg / g.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com