Formwork system for prefabricating waffle slab through ultra-high-performance concrete (UHPC), and construction method of formwork system

A construction method and technology of waffle boards, which are applied in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of inconvenient formwork removal, difficulty in formwork parameter adjustment and recycling, and achieve convenient formwork removal, easy cleaning and reuse , good economic benefits and practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further elaborated below in conjunction with the accompanying drawings.

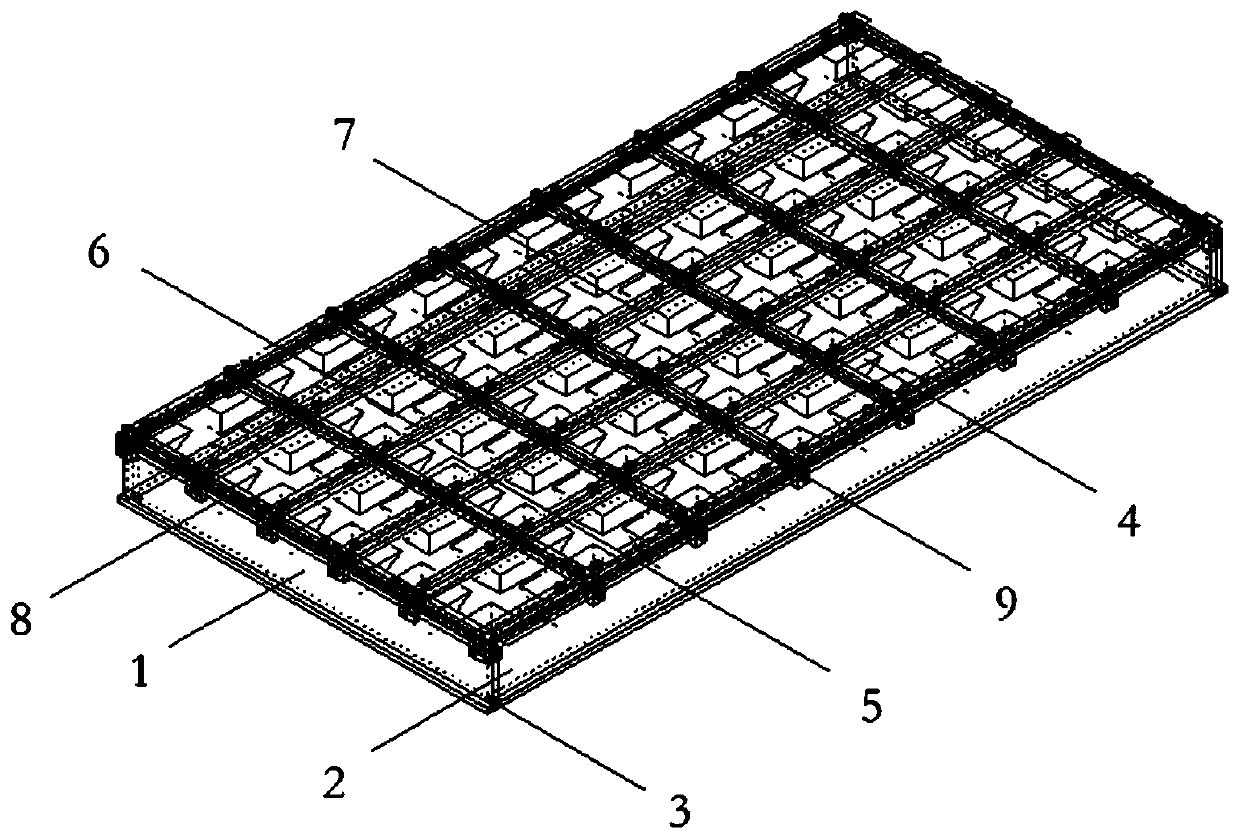

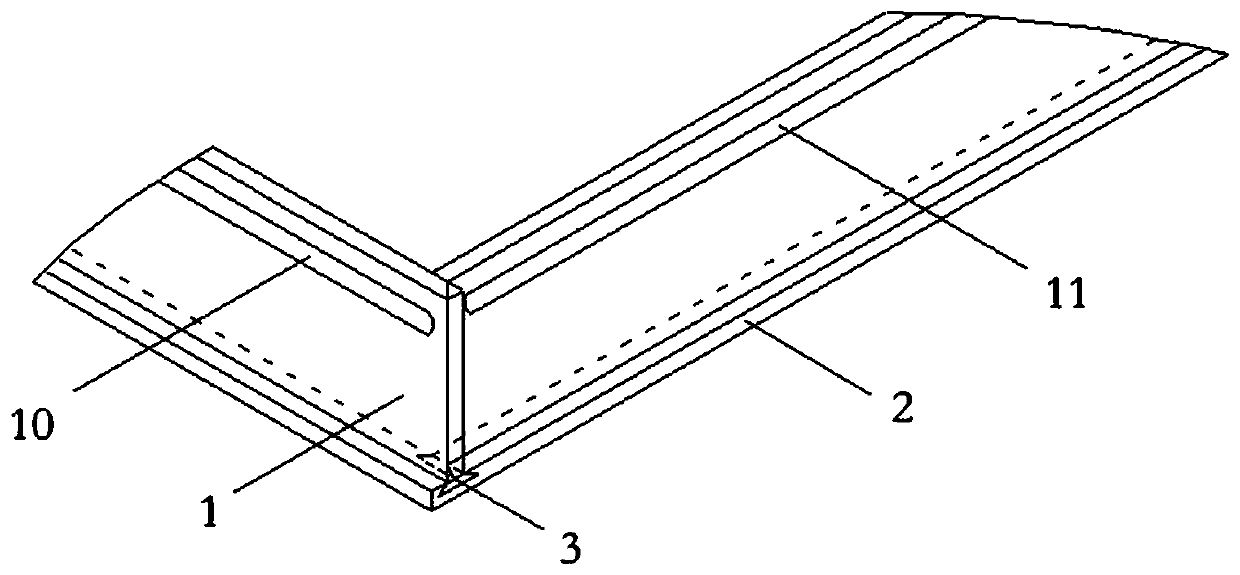

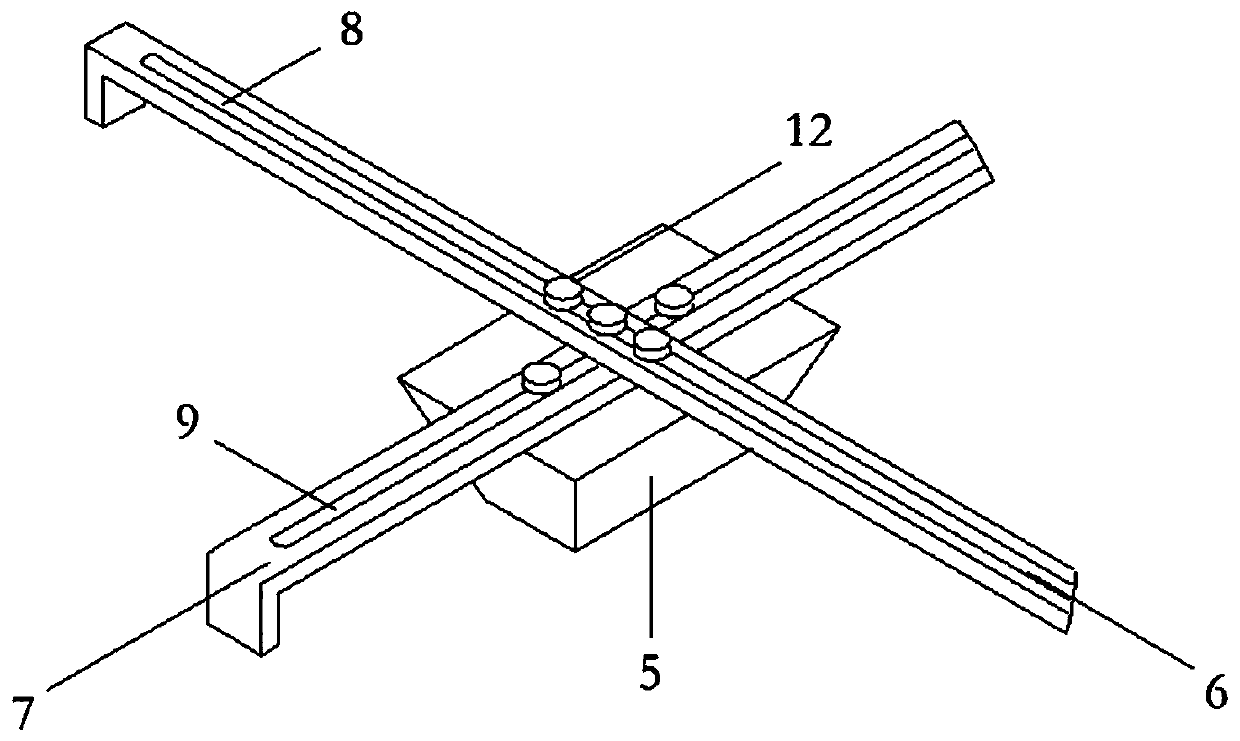

[0028] figure 1 It is a schematic structural diagram of the UHPC waffle plate formwork system described in an embodiment of the present invention. A formwork system for prefabricated UHPC waffle panels, including a pouring trough 3 assembled from steel or aluminum alloy pouring side panels 1 and a pouring bottom plate 2, U-shaped, rectangular or trapezoidal casting blocks 5, horizontal pouring belts 6 and longitudinal casting belts 7, 12 bolts. Among them, the pouring block 5, the horizontal pouring belt 6 and the vertical casting belt 7 are assembled into a pouring grid by bolts 12, and the horizontal casting belt 6 and the longitudinal casting belt 7 are connected to the pouring groove by bolts 12 and the openings 10 and 11 of the lateral and lateral casting side plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com