Double-effect heat exchange system capable of reducing cold-hot impact

A technology of cold and heat shock and heat exchange system, which is applied in the direction of heat exchange equipment, heat exchanger type, heat exchanger shell, etc., can solve problems such as leakage of silicon carbide tubes, peeling of enamel coating, and failure to detect them in time, so as to prevent Peeling, enhanced adhesion, good heat transfer effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

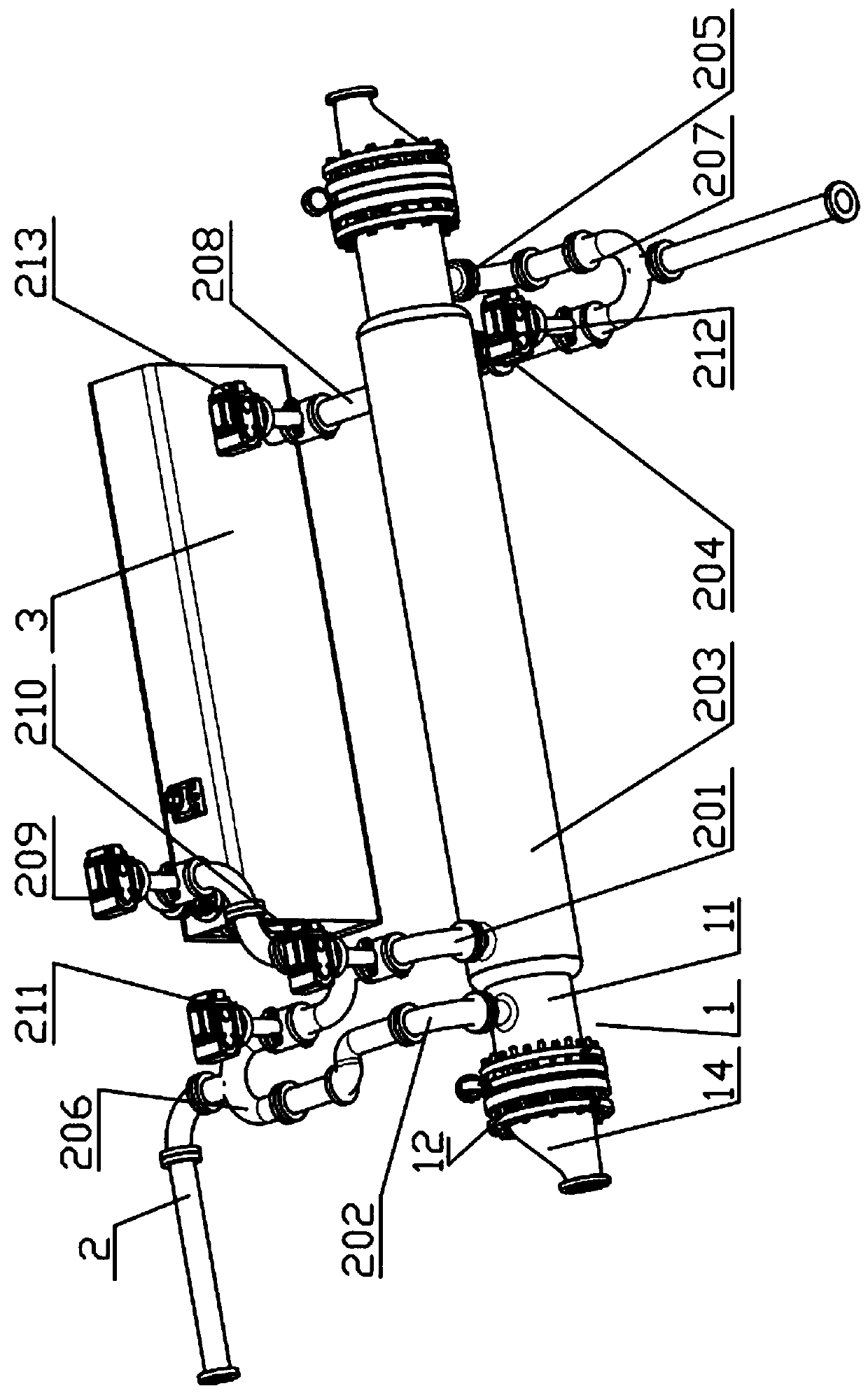

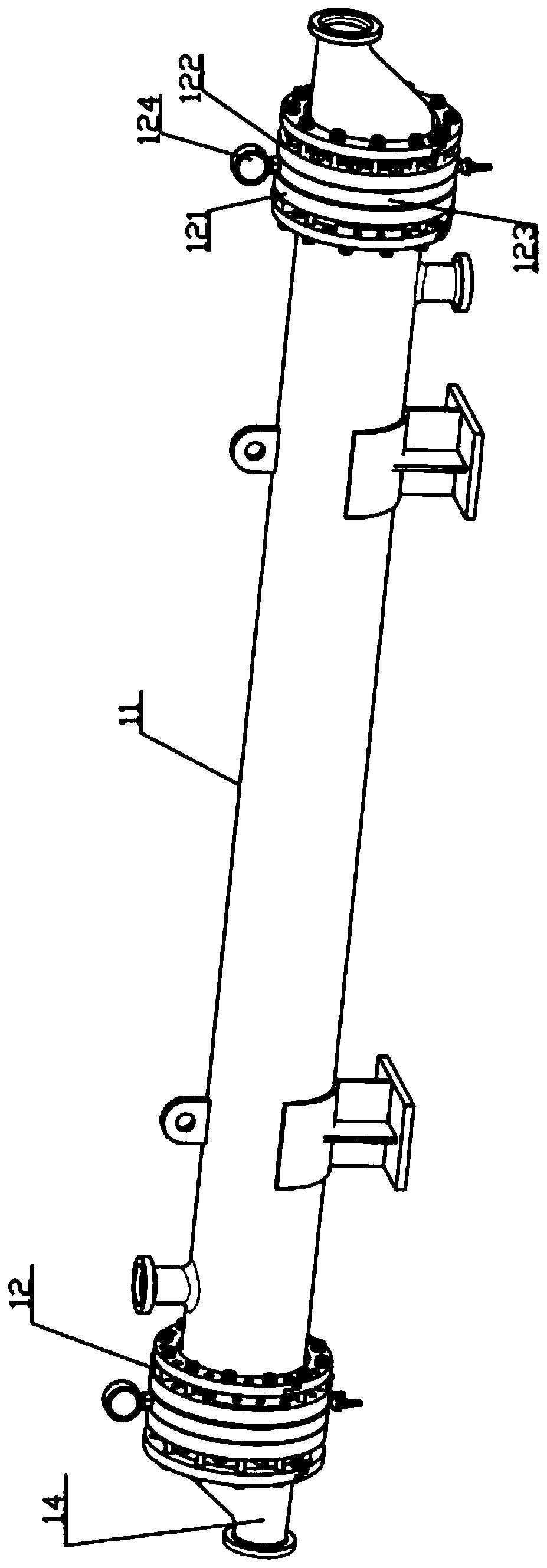

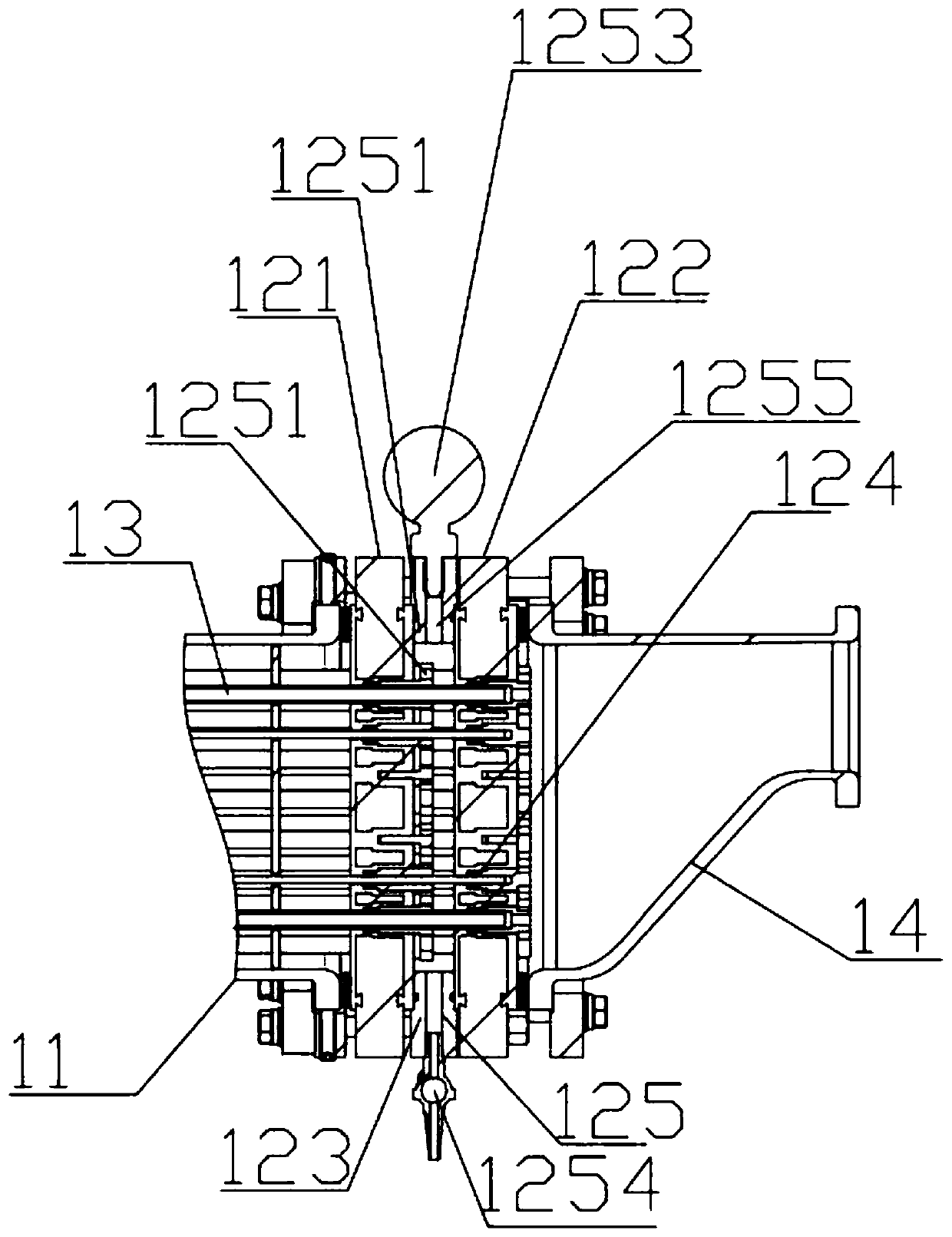

[0032] When using only the external heating of the pipe body 11, the first valve 209 and the second valve 210 can be opened. Heating and heat preservation, while the fifth valve 213 is opened, the first liquid outlet pipe 204 and the third connecting pipe 208 are connected, and the hot water is circulated between the sleeve pipe 203 and the heat source station 3 to ensure that the temperature of the pipe body 11 is constant, so that the silicon carbide Keeping the heat exchanger at a preset temperature has a better heat exchange effect, and will not cause thermal shock to the enamel layer in the pipe body 11, and prolongs the service life by preventing the sealing element from aging.

[0033] One embodiment of the present invention

[0034]In the case of only needing to exchange heat inside the pipe body 11, the first valve 209 and the third valve 211 can be opened. The hot water in the heat source station 3 enters the first connecting pipe 206 through the first liquid inlet p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com