High-resolution electromagnetic speaker with bridge edge method

A high-resolution, loudspeaker technology, applied in transformer/inductor coils/windings/connections, magnets, circuits, etc., can solve problems such as bass leakage, reduce sound conversion efficiency, increase magnetic resistance, and reduce bass reproduction limits frequency, increase the sound conversion efficiency, reduce the effect of magnetoresistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

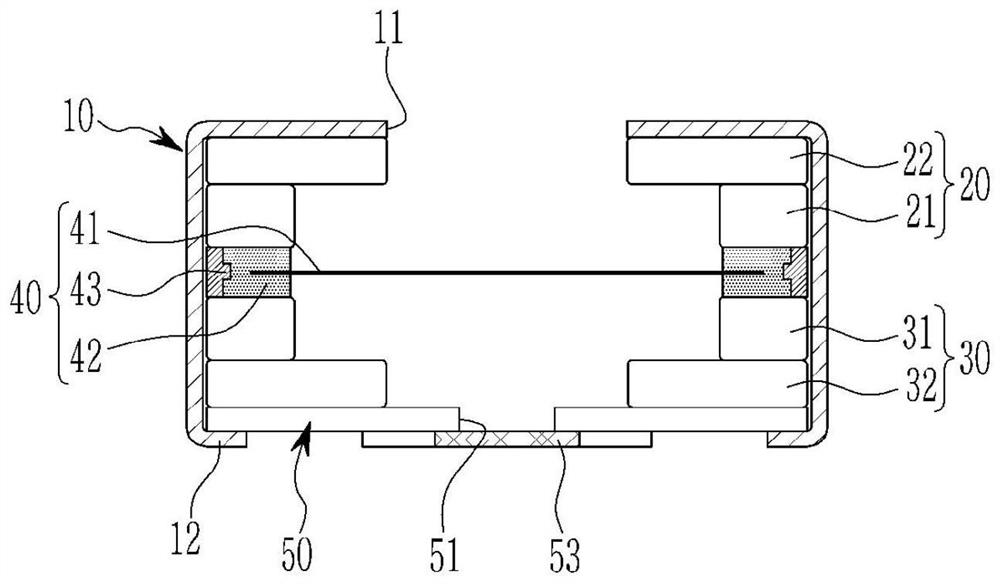

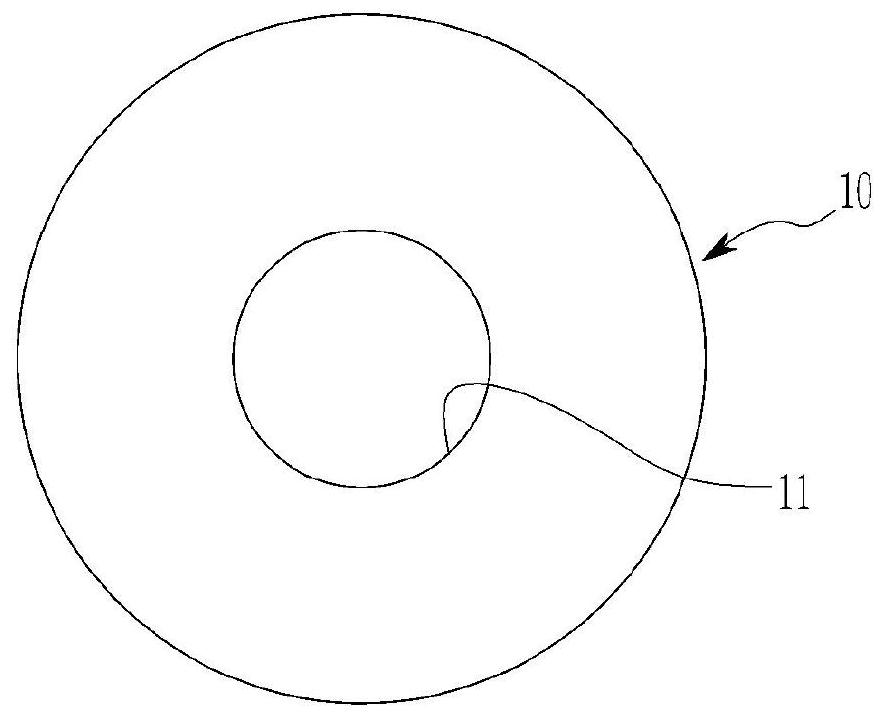

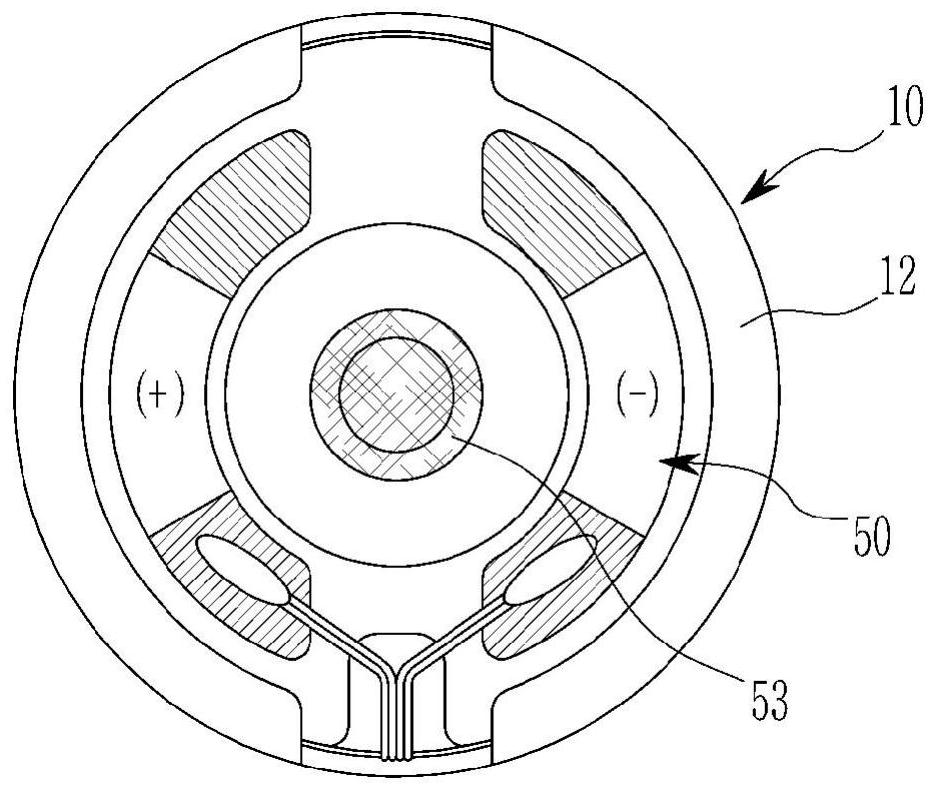

[0055] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. For reference, the size of constituent elements, the thickness of lines, and the like shown in the drawings referred to in explaining the present invention are somewhat exaggerated for easy understanding. In addition, the terms used in the description of the present invention are only defined in consideration of the functions performed in the present invention, and may be changed according to the user, operator's intention, custom, and the like. Therefore, definitions of terms should be defined based on the entire contents of this specification.

[0056] Figure 1 to Figure 8 It is a drawing shown for explaining a high-resolution electromagnetic speaker of a bridge-shaped edge type according to an embodiment of the present invention. Such a high-resolution electromagnetic speaker of one embodiment is an electromagnetic speaker for a full...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com