Barbary wolfberry fruit hot-air drying method using cold ion pretreatment

A hot air drying and pretreatment technology, applied in food drying, application, food preservation, etc., can solve the problems of physical and chemical quality degradation such as color degradation of agricultural products, high cost of vacuum freeze-drying, unfavorable large-scale production, etc., to achieve color and other physical and chemical The effect of good quality, shortened drying time, and increased processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

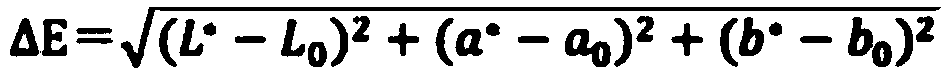

Method used

Image

Examples

Embodiment 1

[0039] Select fresh goji berries with no mold, no obvious damage, and the same size, wash with tap water, drain, and remove surface moisture with absorbent paper. Air is used as the source of cold plasma emission, and the parameters of the cold ion device are set as follows: the distance between the nozzle of the device and the wolfberry sample is 6cm, the flow rate of the cold plasma is 3L / min, the pulse frequency is 20kHz, and the power is 750w. Lycium barbarum samples were treated with cold ions for 15 seconds, and spread in a single layer in a drying tray. The mass of wolfberry in each tray was 149-152 g, and then directly dried with constant temperature and humid hot air. The temperature of the drying room was 65°C. Adjust the humidity to 40% for hot air drying. After 30 minutes, adjust the humidity in the drying room to 20% for hot air drying at a wind speed of 3m / s. When the moisture content reaches 13%, as the drying end point, it takes 12 hours.

Embodiment 2

[0041] Select fresh goji berries with no mold, no obvious damage, and the same size, wash with tap water, drain, and remove surface moisture with absorbent paper. Air is used as the source of cold plasma emission, and the parameters of the cold ion device are set as follows: the distance between the nozzle of the device and the wolfberry sample is 6cm, the flow rate of the cold plasma is 3L / min, the pulse frequency is 20kHz, and the power is 750w. Lycium barbarum samples were treated with cold ion for 30 seconds, and spread in a single layer in a drying tray. The mass of wolfberry in each tray was 149-152 g, and then directly dried with constant temperature and humid hot air. The temperature of the drying room was 65°C. Adjust the humidity to 40% for hot air drying. After 30 minutes, adjust the humidity in the drying room to 20% for hot air drying at a wind speed of 3m / s. When the moisture content reaches 13%, it is used as the end point of drying, and it takes 7 hours.

Embodiment 3

[0043]Select fresh goji berries with no mold, no obvious damage, and the same size, wash with tap water, drain, and remove surface moisture with absorbent paper. Air is used as the source of cold plasma emission, and the parameters of the cold ion device are set as follows: the distance between the nozzle of the device and the wolfberry sample is 6cm, the flow rate of the cold plasma is 3L / min, the pulse frequency is 20kHz, and the power is 750w. Lycium barbarum samples were treated with cold ions for 45 seconds, and spread in a single layer on drying trays. The mass of wolfberries in each tray was 149-152 g, and then directly dried with constant temperature and humid hot air. The temperature of the drying room was 65°C. Adjust the humidity to 40% for hot air drying. After 30 minutes, adjust the humidity in the drying room to 20% for hot air drying at a wind speed of 3m / s. When the moisture content reaches 13%, it is used as the end point of drying, and it takes 7 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com