Grinding device for preparing white tea facial mask

A grinding device and facial mask technology, which is applied in grain processing, etc., can solve the problems of low grinding fineness, failure to meet the particle size requirements of mask powder, and inability to comprehensively and quickly improve skin conditions, and achieve low loss rate and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

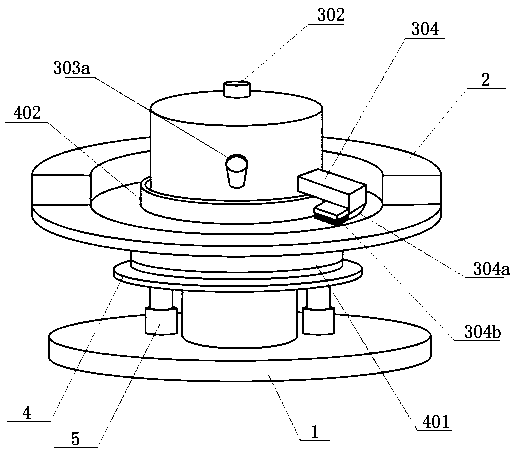

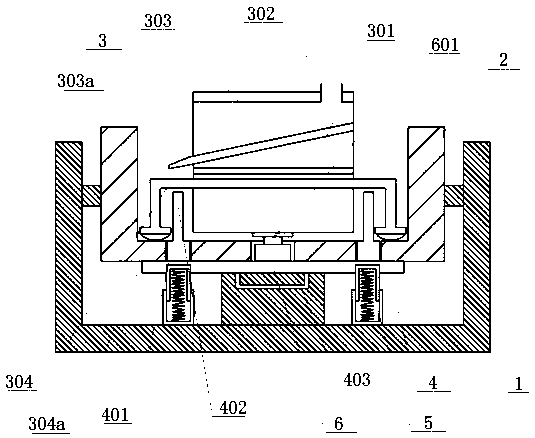

[0031] A grinding device for preparing white tea facial masks, comprising a base 1, a discharge structure 3 erected on the base 1, and a grinding unit arranged between the base 1 and the discharge structure 3 and passing through the lower part of the discharge structure 3 The matching grinding table 2, the base 1 is equipped with a motor 6 that passes through the grinding table 2 and is connected to the discharge structure 3 for driving the rotation of the discharge structure 3. The discharge structure 3 includes The feed inlet 302 on the top, the material guide plate 303 located at the lower part of the feed inlet 302 and obliquely welded inside the barrel, the higher part of the feed guide plate 303 is located on the side of the feed inlet 302, and the material guide plate 303 extends into the cylinder wall and at the end is formed with a discharge port 303a that allows the material to enter the grinding table 2; the grinding unit is arranged at the bottom of the cylinder, in...

Embodiment 2

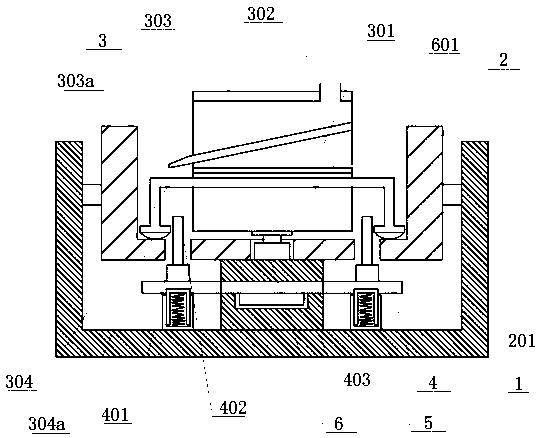

[0033] The difference between this embodiment and Embodiment 1 is that the side wall of the movable block 401 is welded with a stopper 401a that matches the groove 201a on the side wall surface of the opening 201. When the stopper 401a engages When in the groove, the upper surface of the movable block 401 is level with the upper surface of the grinding table 2, which is beneficial to the grinding operation.

Embodiment 3

[0035]A grinding device for preparing white tea facial masks, comprising a base 1, a discharge structure 3 erected on the base 1, and a grinding unit arranged between the base 1 and the discharge structure 3 and passing through the lower part of the discharge structure 3 The matching grinding table 2, the base 1 is equipped with a motor 6 that passes through the grinding table 2 and is connected to the discharge structure 3 for driving the rotation of the discharge structure 3. The discharge structure 3 includes The feed inlet 302 on the top, the material guide plate 303 located at the lower part of the feed inlet 302 and obliquely welded inside the barrel, the higher part of the feed guide plate 303 is located on the side of the feed inlet 302, and the material guide plate 303 extends into the cylinder wall and at the end is formed with a discharge port 303a that allows the material to enter the grinding table 2; the grinding unit is arranged at the bottom of the cylinder, inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com