Waterproof thermal-insulating heat-preservation coating and construction process thereof

A technology for thermal insulation and coating, applied in the field of thermal insulation materials, can solve the problems of reduced thermal insulation performance of silicate thermal insulation coatings, influence of strength and thermal insulation, easy water absorption, etc., to achieve good mechanical strength and thermal insulation effect, improve Curing effect, the effect of improving profits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

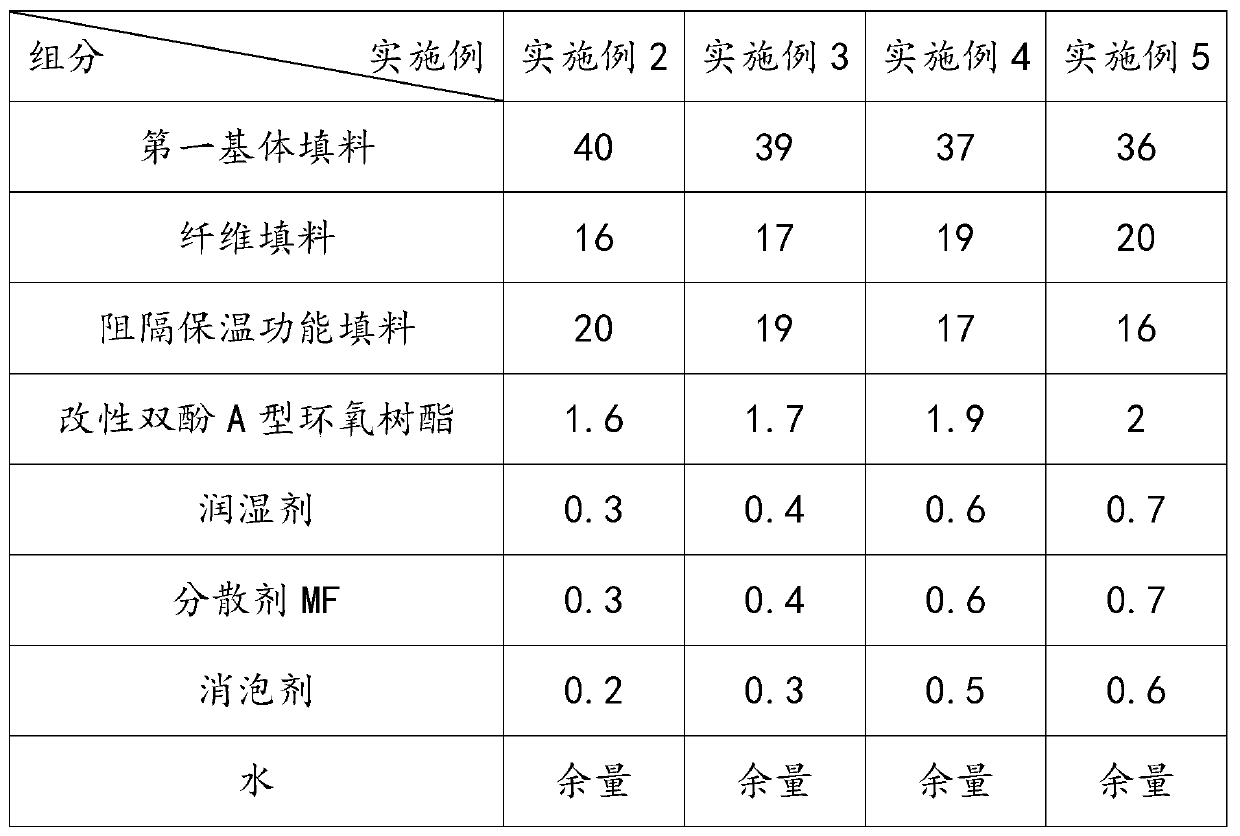

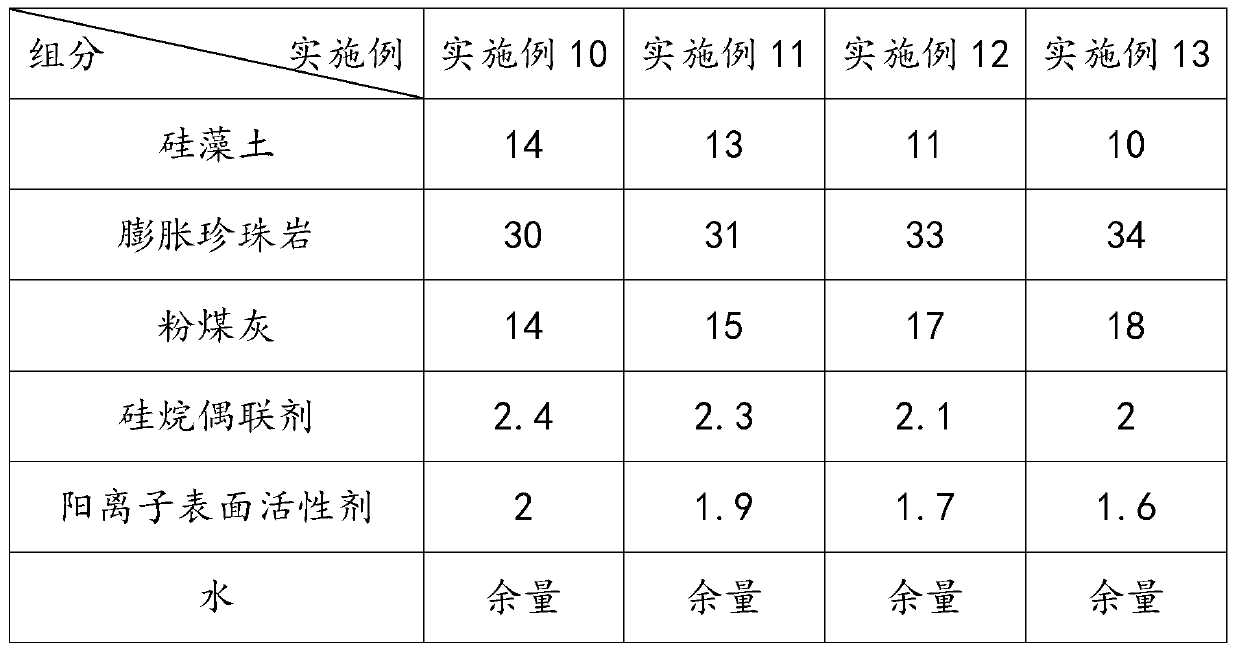

[0122] The difference between Embodiments 10-13 and Embodiment 1 is that the first matrix filler includes the following raw materials in weight percent:

[0123]

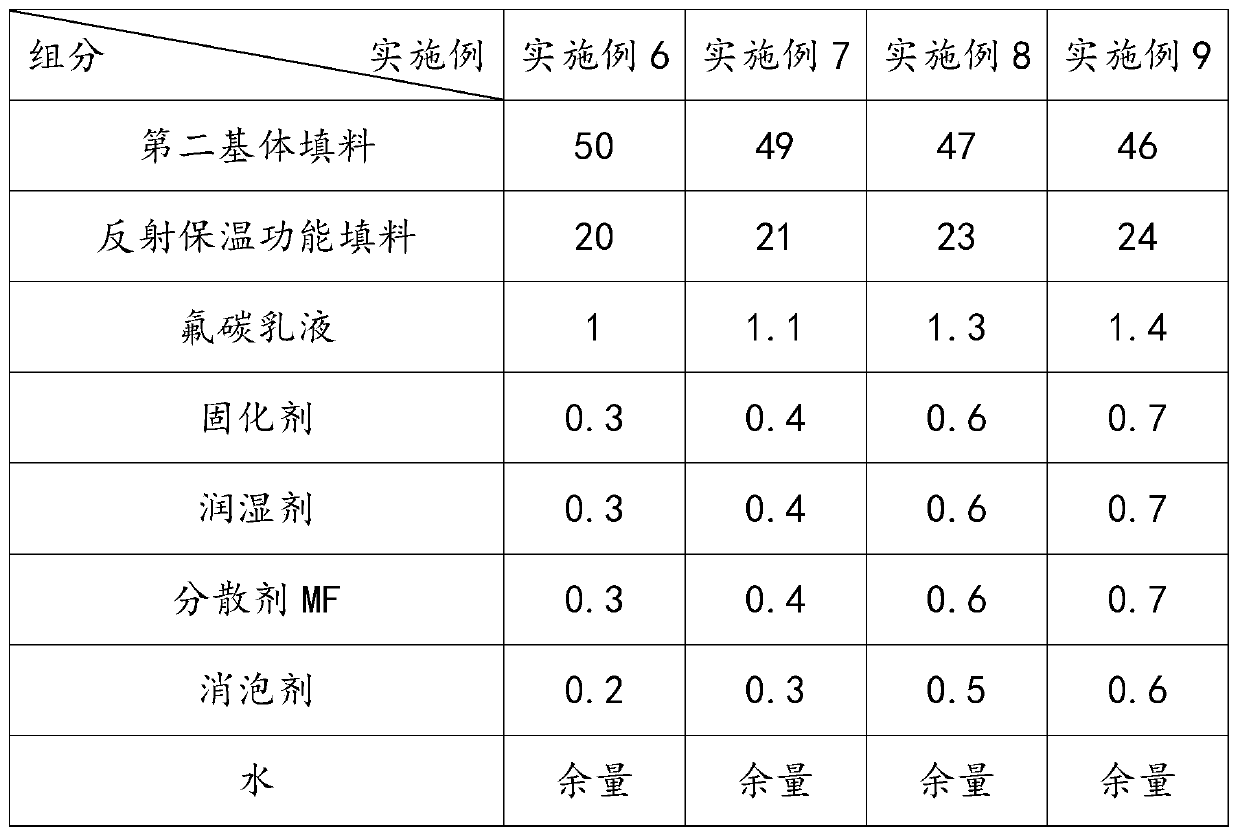

[0124] The difference between Embodiment 14-17 and Embodiment 1 is that the second matrix filler includes the following raw materials in weight percentage:

[0125]

[0126] The difference between Embodiment 18-21 and Embodiment 1 is that the fibrous filler comprises the following raw materials in weight percent:

[0127]

[0128]

[0129] The difference between Examples 22-25 and Example 1 is that the barrier and thermal insulation functional fillers include the following raw materials in percentage by weight:

[0130]

[0131] The difference between Examples 26-29 and Example 1 is that the reflective thermal insulation functional filler includes the following raw materials in weight percentage:

[0132]

[0133] The difference between Embodiment 30-33 and Embodiment 1 is that the modified acryla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com