Production process of ultra-wide steel plate

A production process and steel plate technology, which is applied in the production process field of ultra-wide steel plates, can solve the problems of difficult control of rolling plates, high alloy composition, and large thermal deformation resistance, and achieves overcoming difficulties in rolling process, high alloy composition, elimination of effect of stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

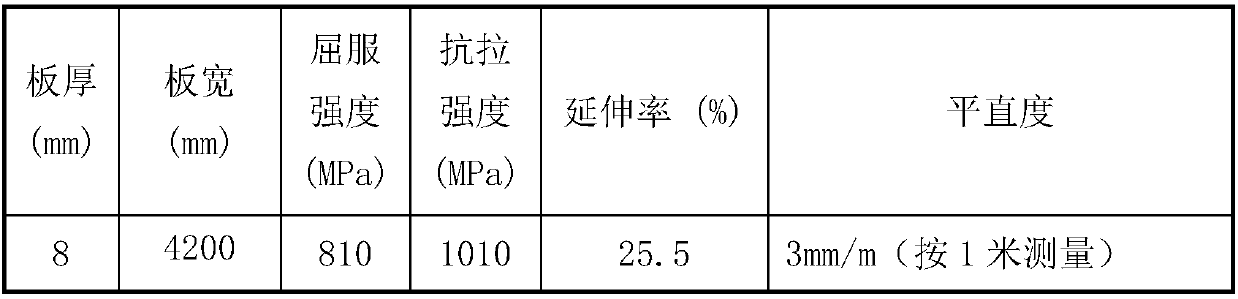

Embodiment 1

[0032] The thickness of the 50Mn2V steel plate for the ultra-wide specification saw blade substrate processed in this embodiment is 8mm, and the width is 4200mm, and its composition is calculated by mass percentage as C: 0.53%, Si: 0.27%, Mn: 1.60%, P: 0.012 %, S: 0.002%, V: 0.13%, Cr: 0.20%, Ni: 0.05%, Cu: 0.016%, Ni: 0.012%, the balance is iron and unavoidable impurity elements; carbon equivalent = 0.85.

[0033] The saw blade substrate is prepared with 50Mn2V steel plate using the following process:

[0034]1) Billet smelting: molten steel is smelted in a converter, sent to LF refining furnace and RH refining furnace for refining. After the RH furnace is finished, the hydrogen content is 0.68ppm, and then the continuous casting is cast at a constant speed of 0.1m / min. The cast billet, after final cutting, has a size of about 150mm×2600mm×3500mm.

[0035] 2) Heating process: use continuous furnace heating, strictly control the heating time and heating temperature of each se...

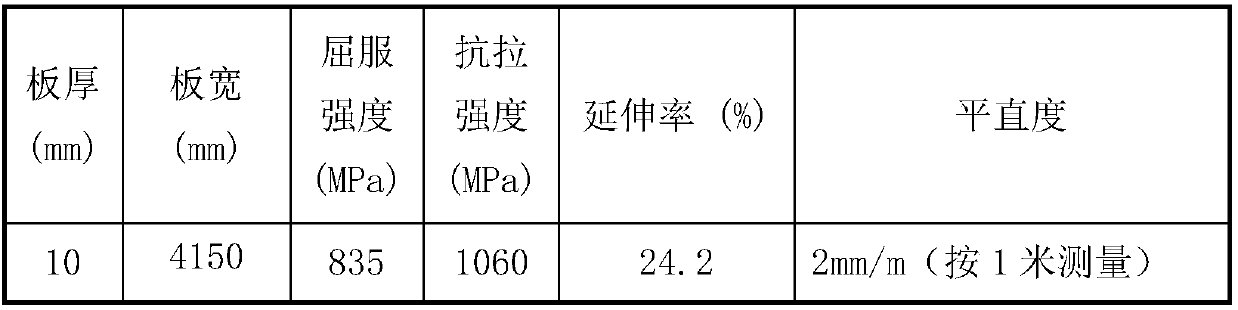

Embodiment 2

[0045] The thickness of the steel 50Mn2V for the ultra-wide specification saw blade substrate of this embodiment is 10mm, and the width is 4150mm, and its composition is calculated by mass percentage: C: 0.53%, Si: 0.27%, Mn: 1.60%, P: 0.012% , S: 0.002%, V: 0.13%, Cr: 0.20%, Ni: 0.05%, Cu: 0.016%, Ni: 0.012%, and unavoidable impurity elements; carbon equivalent = 0.85

[0046] The 50Mn2V steel plate used for the saw blade substrate with a thickness of 10mm and a width of 4150mm is prepared by the following process:

[0047] 1) Billet smelting: molten steel is smelted by converter, sent to LF refining furnace and RH refining furnace for refining. After the RH furnace is finished, the hydrogen content is 0.70ppm, and then the continuous casting is cast at a constant speed of 0.1m / min, and the casting Billet, after cutting, the billet size is about 150×2600×3200mm.

[0048] 2) Heating process: use continuous furnace heating, strictly control the heating time and heating tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com