In-situ aluminum-based material preparation method and device

A technology of aluminum-based materials and preparation devices, which is applied in the field of in-situ forming of Al3Ti/Al composite materials, can solve the problems of few practical applications, difficulty in fully stimulating the performance potential of aluminum-based composite materials, and weak basic research

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

[0035] This embodiment provides a method for preparing an in-situ aluminum-based material, which is characterized in that it includes the following steps:

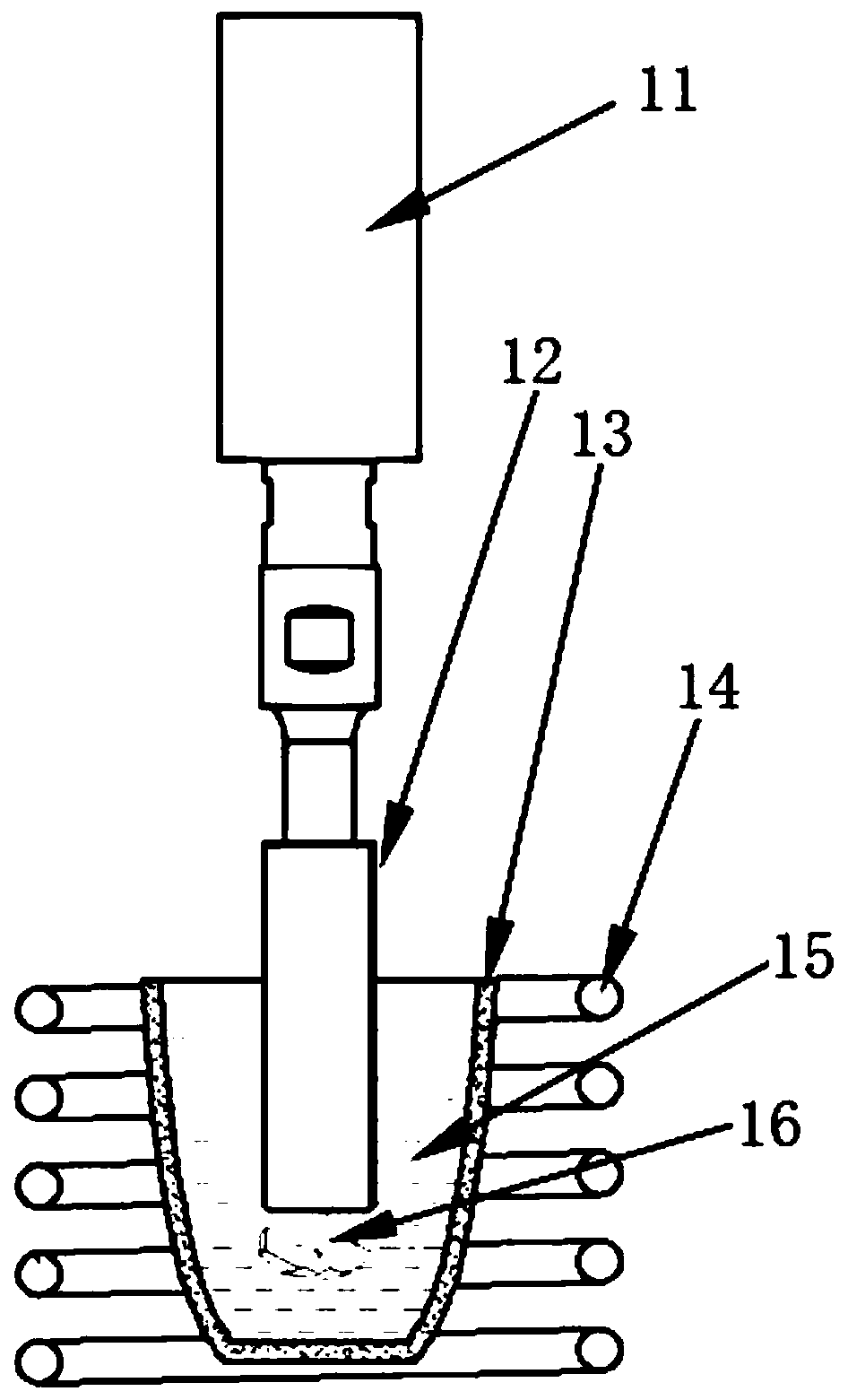

[0036] Step 1. Prepare in-situ Al by induction melting method 3 Ti / Al composite material melt;

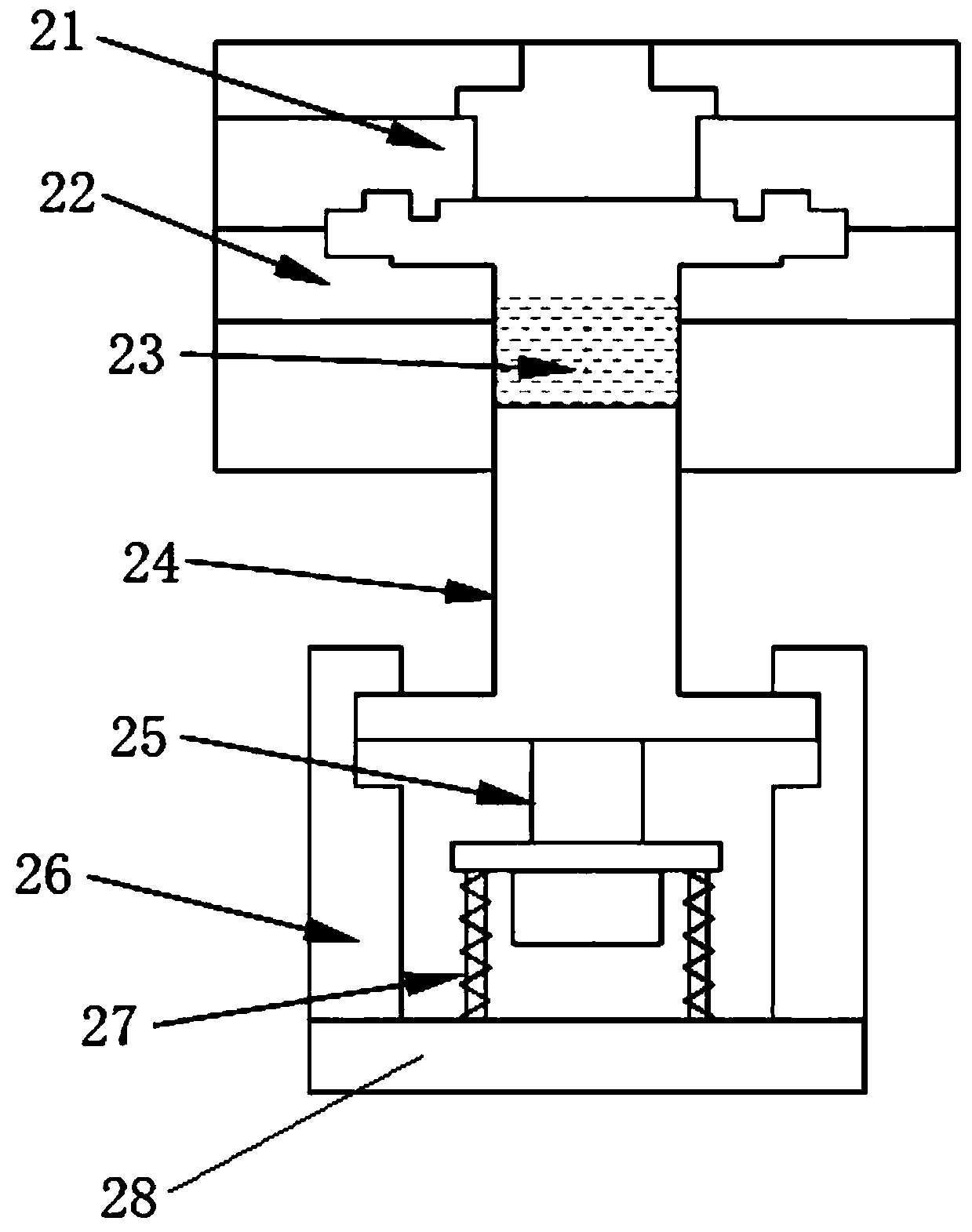

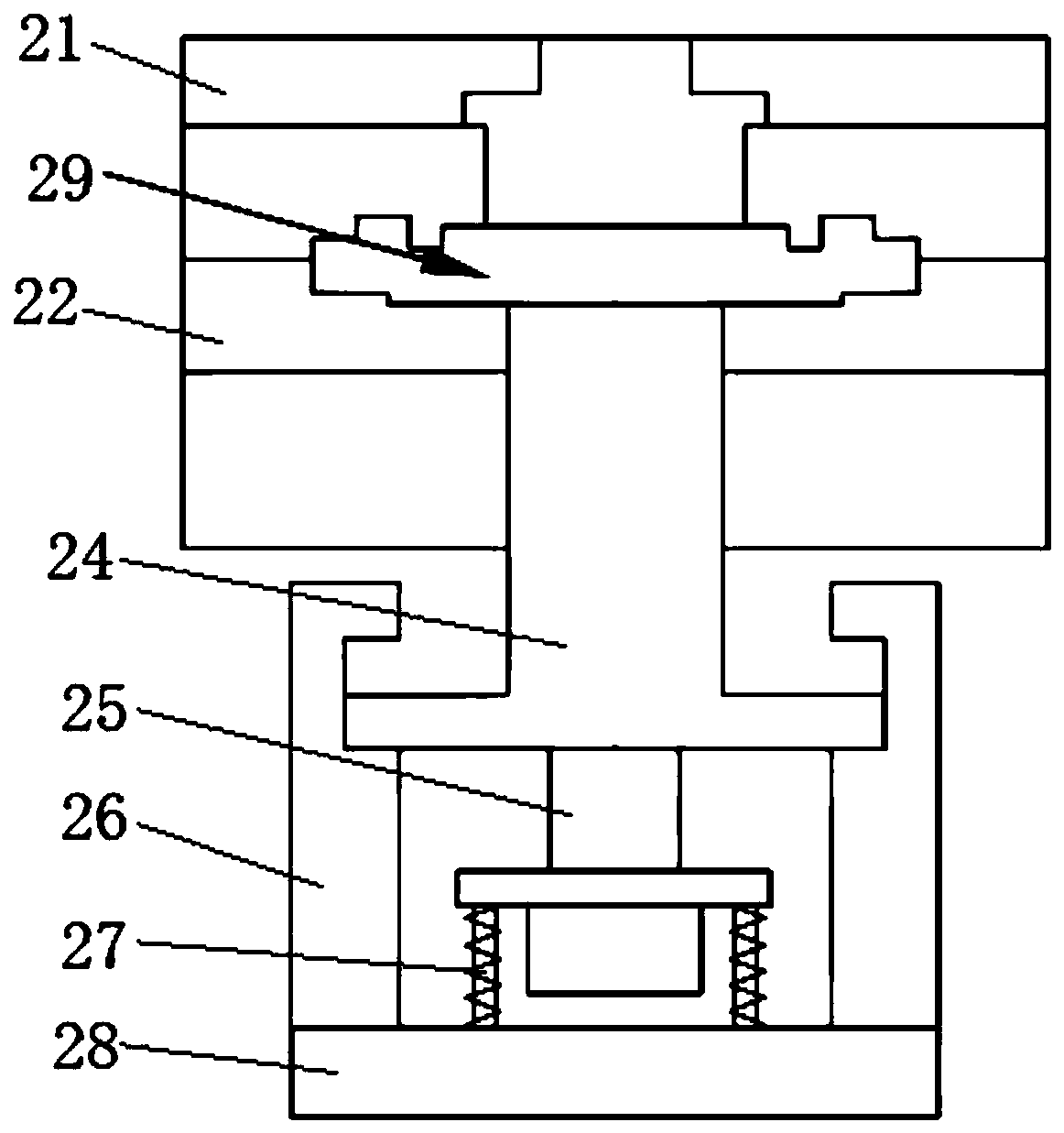

[0037] Step 2, the prepared in-situ Al 3 The melt of Ti / Al composite material is directly poured into the forming mold for extrusion casting, and the cavitation effect and acoustic flow effect generated in the melt by ultrasonic vibration are used in the extrusion casting forming process to control the original Ti particles and the Al melt Reaction behavior, optimize the generated Al 3 The shape and size of Ti;

[0038...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com